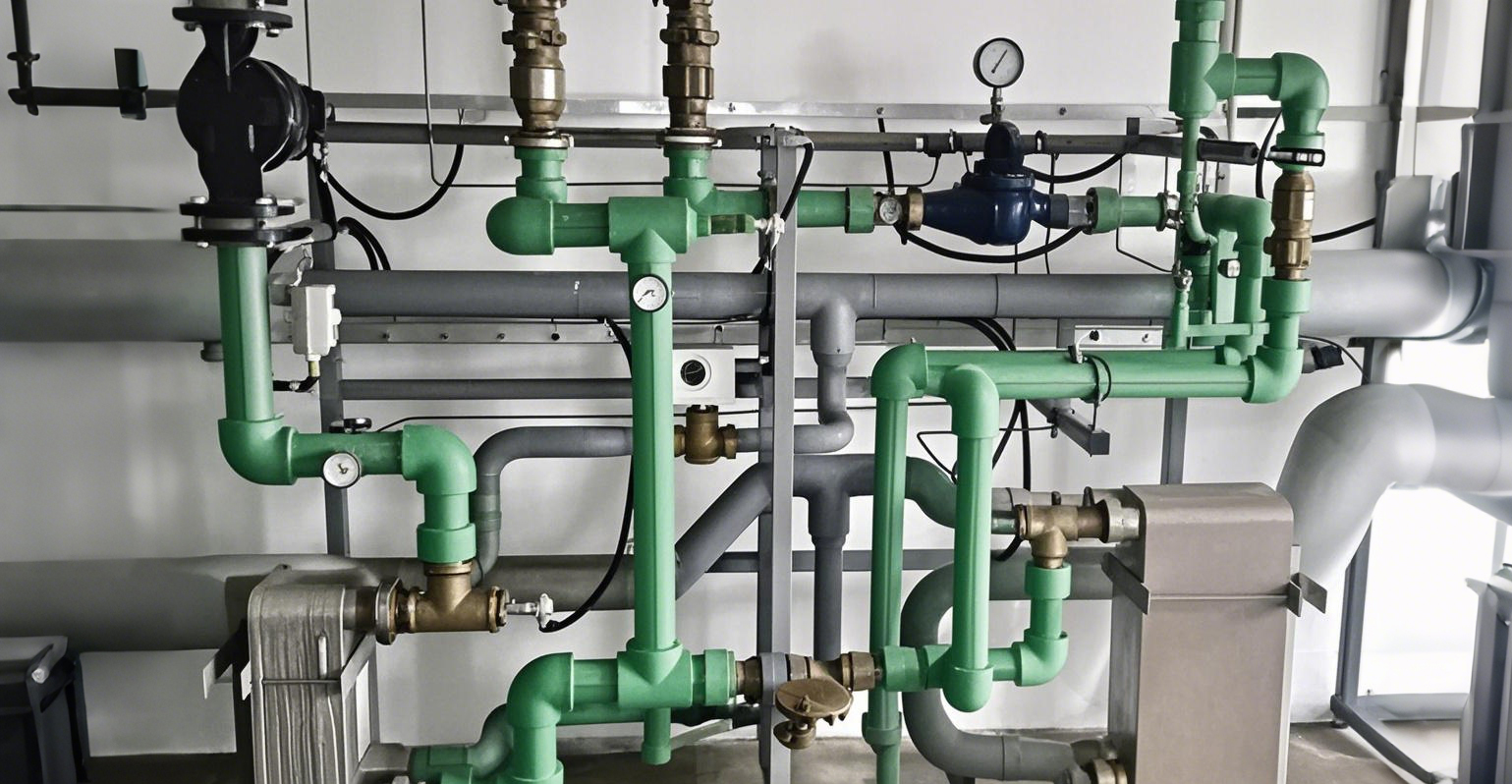

PPR pipe fittings are a game-changer for plumbing systems. They’re known for their durability and resistance to corrosion, making them ideal for long-term use. Their leak-proof connections ensure peace of mind, while their lightweight design simplifies installation. Whether for professionals or DIY enthusiasts, these fittings offer a reliable, cost-effective solution for any plumbing project.

Key Takeaways

- PPR pipe fittings are strong and do not rust, making them great for long-lasting plumbing.

- Heat fusion joins pipes tightly, stopping leaks and improving system strength.

- Checking and cleaning often can make PPR fittings last longer and work better.

What Are PPR Pipe Fittings?

Definition and Composition

PPR pipe fittings are essential components in modern plumbing systems. Made from polypropylene random copolymer (PPR), these fittings are designed to connect pipes securely and efficiently. The material’s unique properties, such as high resistance to heat and chemicals, make it ideal for both residential and industrial applications.

One standout feature of PPR is its ability to withstand extreme temperatures, making it suitable for hot and cold water systems. Additionally, its non-toxic and eco-friendly nature ensures safe water transportation without contamination. The chemical composition of PPR fittings also provides excellent resistance to acids, alkalis, and solvents, ensuring durability in various environments:

- Resistance to Acids: PPR remains stable when exposed to acidic solutions.

- Alkali Resistance: It resists damage from alkaline substances.

- Resistance to Solvents: PPR maintains integrity in industrial settings.

- Oxidation Resistance: It prevents degradation caused by oxygen exposure.

These qualities make PPR pipe fittings a reliable choice for long-term plumbing solutions.

Common Applications in Plumbing Systems

PPR pipe fittings are widely used in diverse plumbing applications. Their versatility and durability make them a preferred choice for both residential and commercial projects. Here are some common uses:

- Residential Plumbing: Ideal for hot and cold water supply systems in homes.

- Commercial Plumbing: Frequently used in office buildings, hotels, and hospitals.

- Industrial Applications: Suitable for transporting chemicals and other fluids in factories.

- Irrigation Systems: Perfect for agricultural and landscaping purposes.

According to industry standards like DIN 8077/8078 and EN ISO 15874, PPR pipe fittings meet stringent quality and safety requirements. These certifications ensure their reliability in various plumbing systems.

Did you know? The heat fusion welding process used with PPR fittings creates a leak-proof connection, reducing maintenance costs and enhancing efficiency.

With their lightweight design and resistance to corrosion, PPR pipe fittings simplify installation and ensure long-lasting performance. Whether for a small home project or a large industrial setup, they provide a dependable solution for plumbing needs.

Key Features of PPR Pipe Fittings

Durability and Long-Term Reliability

PPR pipe fittings are built to last. Their structural resilience allows them to handle impacts, even in cold weather, without cracking. This durability ensures they remain functional across a wide range of operating temperatures. Under normal conditions, these fittings can last over 50 years, making them a cost-effective choice for long-term plumbing solutions.

Unlike metal fittings, which may corrode or degrade over time, PPR fittings maintain their integrity. They resist mechanical stress and chemical degradation, thanks to the use of high-grade PPR resin. Additives like UV stabilizers and antioxidants further enhance their lifespan by protecting against environmental factors.

Resistance to Corrosion and Chemicals

One of the standout features of PPR pipe fittings is their exceptional resistance to corrosion and chemicals. This makes them ideal for transporting water and other fluids without the risk of contamination. Laboratory tests, such as immersion testing and accelerated aging, have shown that PPR fittings can withstand exposure to various chemicals without significant physical changes.

| Testing Method | Description |

|---|---|

| Immersion Testing | Involves immersing PPR samples in chemicals to observe physical and weight changes. |

| Accelerated Aging Tests | Simulates long-term exposure to predict chemical resistance in a shorter timeframe. |

This resistance ensures that PPR fittings perform reliably in both residential and industrial environments, reducing maintenance needs and extending their service life.

Thermal Stability for Hot and Cold Water Systems

PPR pipe fittings excel in handling both hot and cold water systems. They can withstand constant temperatures up to 70°C and short-term exposure to temperatures as high as 100°C. This makes them suitable for a variety of applications, from residential plumbing to industrial systems.

| Pressure Class | Working Pressure (at 20°C) | Max Continuous Temperature |

|---|---|---|

| S5/PN10 | 10 bar (1.0MPa) | 70°C (hot water) |

| S4/PN12.5 | 12.5 bar (1.25MPa) | 80°C (industrial applications) |

| S2.5/PN20 | 20 bar (2.0MPa) | 95°C (high-temperature systems) |

Thermal cycling tests have demonstrated that PPR fittings can endure thousands of temperature changes without failure. This stability ensures reliable performance in demanding conditions.

Leak-Proof Connections with Heat Fusion Technology

Heat fusion technology sets PPR pipe fittings apart from other options. This process involves melting the pipe and fitting together, creating a single, homogeneous piece. The result? A completely leak-proof and corrosion-resistant connection.

This advanced technology not only ensures a secure fit but also reduces the risk of future maintenance. By eliminating potential weak points, heat fusion provides peace of mind for both homeowners and professionals.

Lightweight and Easy to Handle

PPR pipe fittings are incredibly lightweight, making them easy to handle and transport. This feature simplifies installation, especially in large-scale projects. The reduced weight also lowers labor and transportation costs, enhancing overall efficiency.

For DIY enthusiasts, the lightweight nature of PPR fittings makes them a user-friendly option. Whether you’re working on a small home repair or a larger plumbing project, these fittings save time and effort.

Eco-Friendly and Non-Toxic Material

PPR pipe fittings are made from non-toxic, eco-friendly materials. They ensure safe water transportation without introducing harmful substances. This makes them an excellent choice for residential plumbing, where water quality is a top priority.

Additionally, their long lifespan and resistance to wear reduce waste, contributing to a more sustainable plumbing solution. Choosing PPR fittings means investing in a product that’s good for both your home and the environment.

Installation Tips for Reliable Connections

Essential Tools for Installation

Installing PPR pipe fittings requires the right tools to ensure a secure and leak-proof connection. Here’s a list of essential tools every installer should have:

- Pipe Cutter: For clean and precise cuts on PPR pipes.

- Heat Fusion Machine: A must-have for creating seamless connections through heat fusion.

- Measuring Tape: To ensure accurate pipe lengths.

- Marker or Pencil: For marking cutting points.

- Deburring Tool: To smooth out rough edges after cutting.

- Safety Gear: Gloves and safety goggles to protect against heat and sharp edges.

Using these tools simplifies the installation process and ensures professional-quality results. Heat fusion, in particular, is a critical step that requires precision and the right equipment.

Tip: Investing in high-quality tools can save time and reduce the risk of errors during installation.

Step-by-Step Installation Guide

Follow these steps to install PPR pipe fittings correctly:

- Measure and Cut: Use a measuring tape to determine the required pipe length. Cut the pipe cleanly using a pipe cutter.

- Deburr the Edges: Smooth out the cut edges with a deburring tool to prevent uneven connections.

- Mark the Insertion Depth: Use a marker to indicate how far the pipe should be inserted into the fitting.

- Heat the Pipe and Fitting: Set the heat fusion machine to the recommended temperature (usually around 260°C). Heat both the pipe and fitting for the specified time.

- Join the Components: Quickly insert the pipe into the fitting, aligning them properly. Hold them in place for a few seconds to allow the material to fuse.

- Cool and Inspect: Let the connection cool naturally. Inspect the joint to ensure it’s seamless and leak-proof.

This process highlights why PPR pipe fittings are favored for their ease of installation. Heat fusion not only speeds up the process but also enhances the durability and reliability of the system. For example, a project involving 3,500 feet of PPR pipes reported zero leaks after installation, showcasing the effectiveness of this method.

| Evidence Type | Details |

|---|---|

| Installation Process | The installation of nearly 3,500 ft of Aquatherm Blue Pipe was completed with zero leaks reported. |

| Training Effectiveness | CSU maintenance staff noted that the training was effective, allowing them to cut installation time by 25%. |

| Cost Savings | CSU saved an estimated 20% on labor costs using PP-R compared to traditional materials. |

Common Mistakes to Avoid

Even with the right tools and steps, mistakes can happen. Here are some common errors to watch out for:

- Incorrect Heating Time: Overheating or underheating the pipe and fitting can weaken the connection.

- Misalignment: Failing to align the pipe and fitting properly during heat fusion can result in leaks.

- Skipping Deburring: Rough edges can compromise the seal and lead to leaks over time.

- Rushing the Cooling Process: Moving the joint before it cools completely can weaken the bond.

Avoiding these mistakes ensures a reliable and long-lasting plumbing system. Proper training and attention to detail can significantly reduce errors and improve installation success rates.

Safety Precautions During Installation

Safety should always be a priority when installing PPR pipe fittings. Here are some key precautions to follow:

- Wear Protective Gear: Use gloves and safety goggles to protect against burns and sharp edges.

- Follow Manufacturer Guidelines: Adhere to the recommended heating times and temperatures for heat fusion.

- Ensure Proper Ventilation: Work in a well-ventilated area to avoid inhaling fumes from the heat fusion process.

- Comply with Regulations: Familiarize yourself with OSHA and ANSI standards to ensure a safe working environment.

| Regulation Type | Description |

|---|---|

| OSHA Standards | Set and enforce standards for safe working conditions, covering machine safety, hazardous energy control, and PPE requirements. |

| ANSI Standards | Provide best practices for machinery safety, including guidelines on risk assessment and machine guarding. |

| Local Requirements | Vary by jurisdiction and must be researched to ensure compliance with all applicable safety regulations. |

By following these precautions, installers can minimize risks and ensure a safe and efficient installation process.

Note: Always double-check your tools and equipment before starting the installation to avoid unexpected issues.

Maintenance and Longevity

Regular Inspection and Monitoring

Regular inspections keep plumbing systems in top shape. Checking PPR pipe fittings for signs of wear, leaks, or damage helps catch issues early. A quick visual inspection every few months can prevent costly repairs later. Look for cracks, discoloration, or loose connections. If any problems appear, address them immediately to avoid further damage.

For larger systems, professional monitoring tools can track water pressure and flow rates. These tools detect hidden leaks or blockages that might not be visible. Staying proactive with inspections ensures the plumbing system runs smoothly for years.

Cleaning and Preventing Blockages

Keeping pipes clean is essential for maintaining water flow. Over time, mineral deposits or debris can build up inside PPR pipe fittings. Flushing the system with clean water removes minor blockages. For tougher clogs, use a non-corrosive cleaning solution designed for PPR materials.

Preventing blockages is just as important. Install strainers or filters at key points in the system to catch debris before it enters the pipes. Regularly clean these filters to maintain their effectiveness. A clean system not only improves performance but also extends the lifespan of the fittings.

Tips for Extending the Lifespan of PPR Pipe Fittings

A few simple practices can make PPR pipe fittings last even longer. First, avoid exposing them to direct sunlight for extended periods, as UV rays can weaken the material. Second, maintain consistent water pressure to reduce stress on the fittings. Sudden pressure spikes can cause damage over time.

Additionally, always use high-quality fittings and follow proper installation techniques. Poor-quality materials or incorrect installation can shorten the lifespan of the system. Finally, schedule periodic maintenance with a professional plumber to ensure everything stays in excellent condition.

Pro Tip: Investing in high-quality PPR pipe fittings from the start saves money and effort in the long run.

PPR pipe fittings deliver unmatched reliability with their corrosion resistance, durability, and leak-proof design. Their ability to withstand high temperatures and long lifespan makes them ideal for modern plumbing systems. These recyclable fittings align with sustainable construction practices, offering a dependable and eco-friendly solution. For more details, contact Kimmy at kimmy@pntek.com.cn or 0086-13306660211.

FAQ

1. How long do PPR pipe fittings last?

PPR pipe fittings can last over 50 years under normal conditions. Their durability makes them a cost-effective choice for long-term plumbing solutions.

2. Are PPR pipe fittings safe for drinking water?

Yes, PPR fittings are made from non-toxic, eco-friendly materials. They ensure safe water transportation without contamination, making them ideal for residential plumbing systems.

3. Can PPR pipe fittings handle high temperatures?

Absolutely! PPR fittings can withstand temperatures up to 95°C, making them suitable for hot water systems and industrial applications.

Tip: Always choose high-quality PPR fittings for better performance and longevity.

Post time: May-09-2025