Energy-efficient plumbing starts with the right materials. PPR fittings stand out for their thermal insulation, durability, and eco-friendliness. They help reduce energy waste and improve water flow. These fittings also ensure a system that lasts longer, making them a smart choice for homes and businesses aiming for sustainability.

Key Takeaways

- PPR fittings keep heat inside pipes, saving energy and money.

- Checking and cleaning pipes often stops problems and saves energy.

- PPR fittings help the planet by cutting pollution and being eco-friendly.

Unique Properties of PPR Fittings for Energy Efficiency

Thermal Insulation to Minimize Heat Loss

PPR fittings excel at keeping water temperatures stable. Their material has low thermal conductivity, which means less heat escapes from hot water pipes. This property reduces the need for reheating water, saving energy in the process. Whether it’s a residential or commercial plumbing system, these fittings help maintain efficiency by minimizing heat loss.

Tip: Insulating your plumbing system with PPR fittings can lower energy bills and improve overall system performance.

Smooth Interior for Enhanced Water Flow

The smooth inner surface of PPR fittings plays a crucial role in optimizing water flow. It reduces friction, allowing water to move effortlessly through the pipes. This design minimizes pressure drops and turbulence, which can otherwise lead to higher energy consumption. Additionally, the smooth interior prevents sediment buildup, ensuring consistent flow over time.

| Feature | Benefit |

|---|---|

| Reduced friction loss | Improves water flow efficiency and lowers pump energy consumption |

| Minimal flow resistance | Prevents deposit accumulation, maintaining optimal water flow |

| Reduced pressure drop | Enhances flow characteristics and decreases energy usage |

Corrosion Resistance for Long-Lasting Durability

Unlike metal pipes, PPR fittings resist corrosion, even when exposed to harsh chemicals or varying water qualities. This durability ensures a longer lifespan for plumbing systems, reducing the need for frequent replacements. Performance tests, such as immersion testing and accelerated aging, confirm their ability to withstand challenging conditions over extended periods.

| Testing Method | Description |

|---|---|

| Immersion Testing | Samples are immersed in chemicals for weeks or months to evaluate resistance. |

| Accelerated Aging Tests | Simulates long-term exposure under severe conditions in a shorter timeframe. |

Note: The corrosion resistance of PPR fittings not only extends their lifespan but also contributes to energy efficiency by maintaining system integrity.

Installation Techniques to Maximize Efficiency with PPR Fittings

Hot Fusion Welding for Leak-Proof Connections

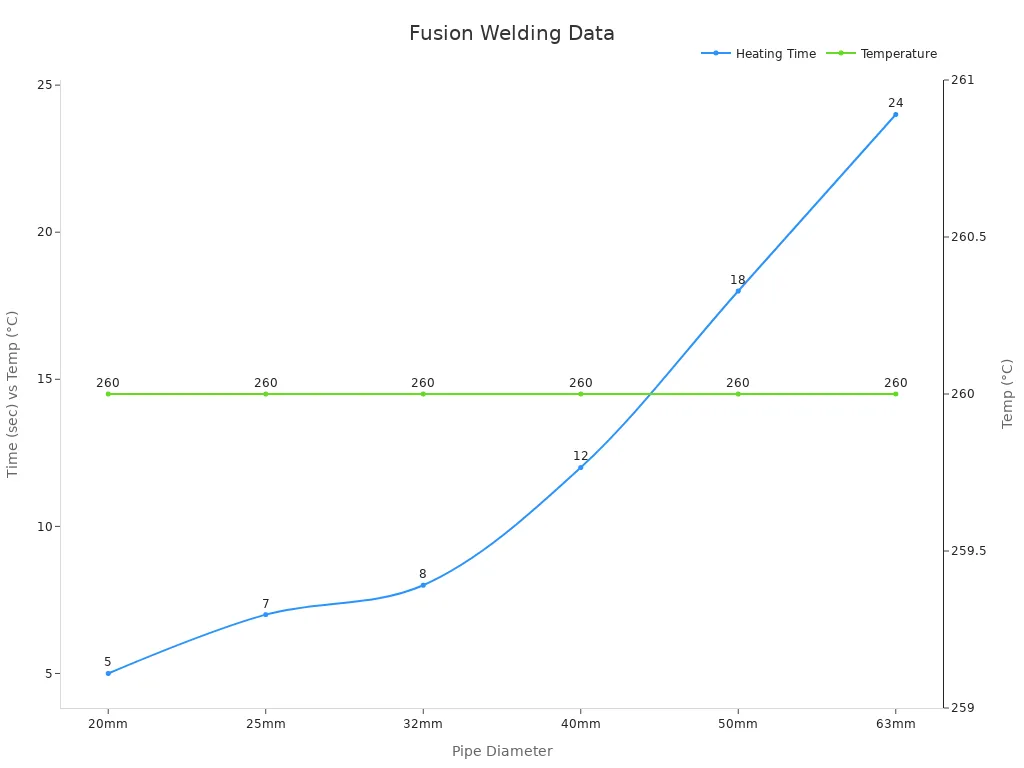

Hot fusion welding is one of the most effective methods for connecting PPR fittings. This technique involves heating the pipe and fitting to a specific temperature, allowing them to fuse into a single, seamless unit. The result is a leak-proof connection that enhances the efficiency and reliability of the plumbing system.

The process requires precise timing and temperature control. For example, a 20mm pipe needs to be heated for 5 seconds at 260°C, while a 63mm pipe requires 24 seconds at the same temperature. Proper alignment during the cooling phase is equally important, as it ensures a strong molecular bond.

| Pipe Diameter | Heating Time | Temperature |

|---|---|---|

| 20mm | 5 seconds | 260°C |

| 25mm | 7 seconds | 260°C |

| 32mm | 8 seconds | 260°C |

| 40mm | 12 seconds | 260°C |

| 50mm | 18 seconds | 260°C |

| 63mm | 24 seconds | 260°C |

Tip: Always follow the recommended heating times and temperatures for each pipe size to achieve the best results.

Proper Pipe Alignment to Prevent Energy Loss

Proper pipe alignment plays a critical role in maintaining energy efficiency. Misaligned pipes can cause unnecessary friction and pressure drops, leading to higher energy consumption. By ensuring that pipes are correctly aligned, the system can operate smoothly and efficiently.

Key guidelines for reducing energy loss include:

- Ensuring pipes are straight and properly supported to minimize friction.

- Avoiding sharp bends or unnecessary fittings that can disrupt water flow.

- Using the correct pipe diameter to match the system’s requirements.

When pipes are aligned correctly, the plumbing system experiences less strain, which helps reduce energy usage and prolong the lifespan of the components.

Supporting Pipes to Maintain System Integrity

Supporting pipes is essential for maintaining the integrity of the plumbing system. Without proper support, pipes can sag or shift over time, leading to misalignment and potential damage. This not only affects the system’s efficiency but also increases the risk of leaks or failures.

To prevent these issues, use pipe clamps or brackets at regular intervals. The spacing between supports depends on the pipe’s diameter and material. For PPR fittings, manufacturers often provide specific guidelines to ensure optimal support.

Note: Regularly inspect pipe supports to ensure they remain secure and free from wear or corrosion.

By combining hot fusion welding, proper alignment, and adequate support, PPR fittings can deliver a highly efficient and durable plumbing system.

Maintenance Practices for Sustained Energy Efficiency

Regular Inspections to Detect Issues Early

Regular inspections are essential for keeping plumbing systems energy-efficient. They help identify small problems before they turn into costly repairs. For example, a loose connection or a minor leak can waste water and energy if left unchecked. By scheduling routine checks, homeowners and businesses can ensure their plumbing systems remain in top condition.

Tip: Create a checklist for inspections. Look for signs of leaks, unusual noises, or changes in water pressure.

Professional plumbers can also use advanced tools like thermal imaging cameras to detect hidden issues. These inspections not only save energy but also extend the lifespan of the system.

Cleaning to Prevent Sediment Buildup

Over time, sediment can accumulate inside pipes and fittings, reducing water flow and increasing energy consumption. Cleaning the plumbing system regularly prevents this buildup and ensures smooth operation. For PPR fittings, a simple flush with clean water is often enough to remove debris.

- Benefits of regular cleaning:

- Improves water flow efficiency.

- Reduces strain on pumps and heaters.

- Prevents long-term damage to the system.

Note: Always follow the manufacturer’s guidelines when cleaning to avoid damaging the fittings.

Replacing Damaged Fittings for Optimal Performance

Damaged or worn-out fittings can compromise the efficiency of a plumbing system. Replacing them promptly ensures optimal performance and prevents energy loss. PPR fittings are known for their durability, but even they may need replacement after years of use or due to accidental damage.

When replacing fittings, it’s important to choose high-quality materials that match the existing system. Proper installation is equally crucial to avoid leaks or misalignments.

Reminder: Keep spare fittings on hand for quick replacements. This minimizes downtime and keeps the system running efficiently.

By following these maintenance practices, plumbing systems can remain energy-efficient and reliable for years to come.

Environmental Advantages of PPR Fittings

Reduced Energy Consumption in Plumbing Systems

PPR fittings help reduce energy use in plumbing systems by retaining heat more effectively than traditional materials. Their low thermal conductivity ensures that hot water stays warm as it travels through the pipes. This means less energy is needed to reheat water, which can significantly lower energy bills. Compared to metal pipes like copper or steel, PPR fittings are much better at conserving heat. This makes them an environmentally friendly choice for both homes and businesses.

Tip: Switching to PPR fittings can make a noticeable difference in energy efficiency, especially in systems that handle hot water frequently.

Lower Carbon Footprint Compared to Traditional Materials

Using PPR fittings can also help reduce the carbon footprint of plumbing systems. Unlike metal pipes, which require energy-intensive processes to produce, PPR fittings are manufactured with less energy. Additionally, their lightweight design reduces transportation emissions. By choosing PPR fittings, homeowners and businesses can contribute to a greener planet while enjoying a durable and efficient plumbing system.

Recyclability and Sustainable Manufacturing

PPR fittings stand out for their recyclability. Once they reach the end of their lifespan, they can be recycled into new products, reducing waste. The manufacturing process for PPR fittings also uses eco-friendly practices, minimizing environmental impact. This combination of recyclability and sustainable production makes PPR fittings a smart choice for those who care about the environment.

Note: Choosing recyclable materials like PPR fittings supports a circular economy and helps reduce landfill waste.

About Our Company

Expertise in Plastic Pipes and Fittings

Our company has built a strong reputation in the plastic pipes and fittings industry. With years of experience, we’ve developed a deep understanding of what it takes to create reliable and efficient products. Industry leaders like Derek Muckle, who has over 25 years of expertise, have contributed to advancements in this field.

| Name | Position | Experience |

|---|---|---|

| Derek Muckle | President of the BPF Pipes Group | Over 25 years in the sector |

| Director of Innovation and Technology at Radius Systems | Developing plastic pipes and fittings for water, wastewater, and gas industries |

This level of expertise ensures that every product meets the highest standards of performance and durability.

Commitment to Quality and Innovation

Quality and innovation are at the heart of everything we do. Our team constantly works to improve designs and manufacturing processes. We invest in innovation and prioritize staff training to stay ahead in the industry.

| Metric Type | Description |

|---|---|

| Financial KPIs | Measures the percentage of capital invested in innovation and the profit impact of innovations. |

| Staff Competency Metrics | Tracks participation in innovation training and study hours required for staff. |

| Leadership Culture Metrics | Assesses how innovative the company’s leadership culture is and identifies areas for improvement. |

This commitment ensures that our products not only meet but exceed customer expectations.

Wide Range of Products for Plumbing and Irrigation

We offer a diverse selection of products designed for plumbing and irrigation systems. From PPR fittings to advanced irrigation valves, our catalog covers a wide range of needs.

| Product/Resource | Description |

|---|---|

| Irrigation Catalog | Comprehensive catalog showcasing irrigation products. |

| Case Studies | Detailed case studies demonstrating product applications. |

| 2000 Series Heavy Duty Irrigation Valves Specifications | Specifications for heavy-duty irrigation valves. |

Our products are designed to deliver efficiency and reliability, making them ideal for both residential and commercial applications.

PPR fittings offer a smart solution for energy-efficient plumbing. Their corrosion resistance and welded joints ensure long-term reliability, unlike traditional materials prone to leaks or damage. These fittings can last up to 50 years, making them a sustainable choice for homes and businesses. Upgrading to PPR fittings enhances durability, reduces energy use, and supports environmental goals.

| Advantage | PPR Fittings | Other Materials (Metal/PVC) |

|---|---|---|

| Corrosion Resistance | Does not corrode, extending service life | Prone to corrosion, reducing lifespan |

| Joint Integrity | Welded joints, less prone to leaks | Mechanically joined, more leak-prone |

| Thermal Expansion | Lower thermal expansion | Higher thermal expansion, risk of damage |

Tip: Choose PPR fittings for a plumbing system that’s efficient, durable, and eco-friendly.

For more information, contact Kimmy at kimmy@pntek.com.cn.

FAQ

What makes PPR fittings better than traditional materials?

PPR fittings resist corrosion, retain heat, and last longer. Their smooth interior improves water flow, making them more efficient and eco-friendly than metal or PVC pipes.

Can PPR fittings handle hot water systems?

Yes! PPR fittings are perfect for hot water systems. Their thermal insulation minimizes heat loss, ensuring energy efficiency and consistent water temperature.

How long do PPR fittings typically last?

PPR fittings can last up to 50 years. Their durability and resistance to wear make them a reliable choice for long-term plumbing solutions.

Tip: Regular maintenance can extend the lifespan of your PPR fittings even further!

Post time: May-08-2025