Plumbing systems have come a long way, and ppr fittings are leading the charge. These fittings stand out for their ability to tackle common plumbing challenges like leaks and corrosion while boosting efficiency. Here’s why they’re a game-changer:

- They handle temperatures from 70°C to 95°C (158°F to 203°F) without breaking a sweat.

- Their low thermal conductivity keeps heat loss or gain to a minimum.

- They resist scaling and corrosion, ensuring fewer repairs and longer service life.

With these benefits, they’re a smart choice for modern plumbing systems.

Key Takeaways

- PPR fittings are strong and don’t rust, lasting 50+ years.

- They don’t lose much heat, saving energy and lowering bills.

- Heat fusion makes tight connections, stopping leaks and water damage.

Unique Properties of PPR Fittings

Durability and Corrosion Resistance

PPR fittings are built to last. Their resistance to corrosion makes them ideal for plumbing systems exposed to water and chemicals. Unlike metal pipes, which can rust or degrade over time, PPR fittings maintain their integrity even in harsh conditions. A study on the mechanical behavior of PPR pipes under pressure highlights their durability. Tests show that these fittings can withstand damage and perform reliably under extreme pressure and temperature. This durability reduces the need for frequent replacements, saving time and money in the long run.

Thermal Insulation and Temperature Tolerance

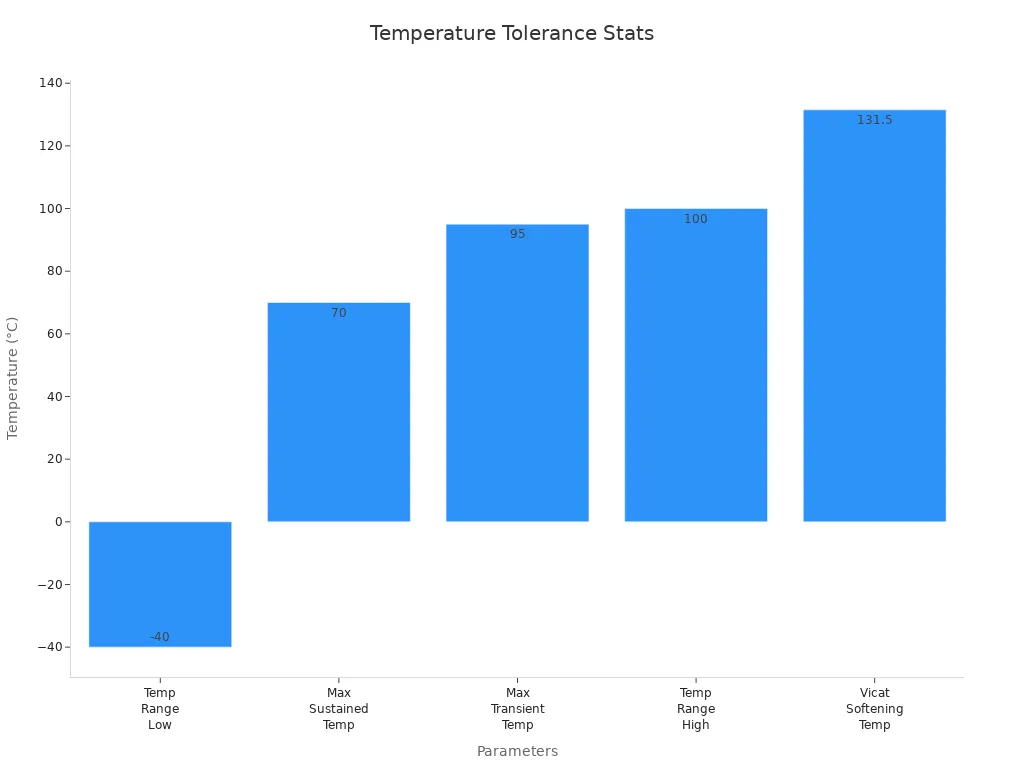

PPR fittings excel in managing temperature. Their low heat conductivity of 0.21 w/mk ensures minimal energy loss, keeping water temperatures stable. Whether it’s freezing cold or scorching hot, these fittings can handle it. They operate effectively in temperatures ranging from -40°C to +100°C, with a maximum sustained working temperature of 70°C. For high-temperature applications, their Vicat softening temperature of 131.5°C ensures reliability. The chart below illustrates their impressive temperature tolerance:

Eco-Friendly and Non-Toxic Material

PPR fittings are a safe and sustainable choice. Made from non-toxic materials, they ensure clean water delivery without contamination. Certified as food-grade pipes under DIN 1998 T2 standards, they meet the highest safety requirements for drinking water systems. Their eco-friendly composition also resists acids, alkalis, and solvents, making them suitable for various environments. By choosing PPR fittings, users contribute to a healthier planet while enjoying a reliable plumbing system.

How PPR Fittings Solve Common Plumbing Issues

Preventing Leaks and Ensuring Secure Connections

Leaks are one of the most frustrating plumbing issues. They waste water, increase utility bills, and can cause structural damage over time. PPR fittings tackle this problem head-on with their innovative heat fusion technology. This method creates leak-proof connections by welding the fittings together, forming a single, seamless unit. Unlike traditional threaded or glued joints, these connections remain secure even under high pressure or temperature fluctuations.

Experimental tests confirm the reliability of PPR fittings in preventing leaks. For instance, during a thermal cycling test, fittings were subjected to 500 cycles of alternating temperatures between 20°C and 95°C. The results showed no joint failures, proving their dimensional stability and ability to withstand extreme conditions. Additionally, long-term hydrostatic pressure tests demonstrated that PPR fittings could endure 1,000 hours at 80°C and 1.6 MPa without visible cracks or degradation.

| Test Type | Parameters | Results |

|---|---|---|

| Short-Term High-Temperature | 95°C: Structural integrity up to 3.2 MPa | No leaks or failures detected. |

| Long-Term Hydrostatic Pressure | 1,000 hours at 80°C, 1.6 MPa | <0.5% deformation, no visible cracks or degradation. |

| Thermal Cycling | 20°C ↔ 95°C, 500 cycles | No joint failures, confirming dimensional stability. |

These results highlight why PPR fittings are trusted for secure and leak-free plumbing systems.

Eliminating Corrosion and Blockages

Corrosion and blockages can wreak havoc on plumbing systems. They reduce water flow, damage pipes, and lead to costly repairs. PPR fittings eliminate these issues thanks to their corrosion-resistant properties. Unlike metal pipes, which can rust or accumulate mineral deposits, PPR fittings maintain smooth inner surfaces that resist scaling and buildup.

Their chemical inertness ensures that they don’t react with water or other substances, making them ideal for environments with high acidity or alkalinity. This feature is particularly beneficial for underground systems, where exposure to ground moisture and salts can accelerate corrosion in traditional pipes. By preventing blockages and corrosion, PPR fittings keep plumbing systems running smoothly for years.

Maintaining Consistent Water Pressure and Flow

Consistent water pressure is essential for a functional plumbing system. PPR fittings excel in this area by ensuring efficient water flow and minimizing pressure loss. Their smooth inner surfaces reduce friction, allowing water to move freely without obstructions. This design prevents turbulence and ensures steady pressure, even in high-demand systems.

Several performance metrics highlight their ability to maintain water pressure and flow:

- PPR fittings resist minerals, salts, and ground moisture, making them ideal for underground systems.

- They maintain strength under long-term burial conditions.

- They perform well under both cold and high-pressure flows.

| Metric | Description |

|---|---|

| Smooth Inner Surfaces | Reduces friction, ensuring efficient water flow. |

| Leak-Proof Connections | Created through heat fusion technology, ensuring reliable water flow. |

| Resistance to Corrosion | Prevents buildup of scale, maintaining smooth water flow over time. |

| High Temperature and Pressure | Suitable for various applications, ensuring durability under extreme conditions. |

Additionally, their lightweight yet strong design makes installation easier, while their resistance to rust ensures long-term functionality. With PPR fittings, users can enjoy consistent water pressure and flow without worrying about interruptions or inefficiencies.

Long-Term Benefits of PPR Fittings

Reduced Maintenance and Repair Costs

Plumbing repairs can be a hassle. They disrupt daily life and often come with hefty bills. PPR fittings help reduce these headaches. Their durability and resistance to corrosion mean fewer breakdowns over time. Unlike metal pipes that rust or develop leaks, PPR fittings maintain their integrity for decades. This reliability translates to fewer service calls and lower repair costs.

The heat fusion technology used in PPR fittings also plays a big role. It creates leak-proof joints that don’t loosen or wear out easily. This secure connection minimizes the risk of water damage, which can lead to expensive repairs. Over time, homeowners and businesses save money by avoiding frequent maintenance and replacements.

Energy Efficiency and Lower Utility Bills

Energy efficiency is a major advantage of PPR fittings. Their low thermal conductivity of 0.21 W/(m·K) ensures minimal heat loss, making them ideal for hot water systems. By maintaining water temperature, they reduce the energy needed to reheat water. This feature is especially beneficial in homes and industries where water heating accounts for a significant portion of energy use.

Here’s how PPR fittings contribute to energy savings:

- They provide 3-5 times better insulation than traditional plastic pipes.

- Leak-proof joints prevent energy loss, saving up to 15% in older systems.

- Their smooth interior surface reduces friction, improving water flow and efficiency.

| Evidence | Description |

|---|---|

| Thermal Conductivity | PPR pipes lose 99.95% less heat compared to copper pipes. |

| Insulation Properties | Superior insulation keeps water hot or cold for longer periods. |

| Leak Prevention | Heat fusion welding ensures no leaks, reducing energy waste. |

| Longevity | A 50-year lifespan means fewer replacements, saving energy over time. |

These features not only lower utility bills but also make PPR fittings an eco-friendly choice for energy-conscious users.

Environmental Sustainability and Longevity

Sustainability is more important than ever. PPR fittings align with this goal by offering a long-lasting and environmentally friendly solution. Made from non-toxic materials, they ensure safe water delivery without harming the environment. Their resistance to chemicals and scaling also prevents contamination, keeping water systems clean and efficient.

The longevity of PPR fittings further enhances their sustainability. With a service life of over 50 years, they reduce the need for frequent replacements. This durability minimizes waste and conserves resources. Additionally, their lightweight design lowers transportation emissions, making them a greener alternative to traditional metal pipes.

By choosing PPR fittings, users contribute to a healthier planet while enjoying a reliable plumbing system. It’s a win-win for both the environment and the user.

PPR fittings offer a reliable and efficient solution for modern plumbing. Their durability, thermal insulation, and eco-friendly design address common issues like leaks and corrosion. With a lifespan exceeding 50 years, they reduce maintenance costs and environmental impact. The table below highlights their key advantages:

| Advantage | Description |

|---|---|

| Durability and Longevity | PPR pipes can last over 50 years, resistant to corrosion and scaling. |

| Leak-Proof | Heat fusion welding creates strong, seamless connections, minimizing leaks. |

| Eco-Friendly | Non-toxic and recyclable, making it environmentally friendly. |

| Cost-Effective | Long lifespan and reduced costs make PPR economical over time. |

Investing in PPR fittings ensures a plumbing system that performs efficiently for decades.

FAQ

What makes PPR fittings better than metal pipes?

PPR fittings resist corrosion, scale buildup, and leaks. Their lightweight design simplifies installation, while their durability ensures a service life of over 50 years.

Can PPR fittings handle extreme temperatures?

Yes! They work in temperatures from -40°C to +100°C. Their Vicat softening temperature of 131.5°C makes them reliable for hot water systems.

Tip: PPR fittings are perfect for both residential and commercial plumbing projects. Their versatility makes them a go-to choice for modern systems.

Are PPR fittings eco-friendly?

Absolutely! PPR fittings are non-toxic, recyclable, and safe for drinking water. Their long lifespan reduces waste, making them a sustainable plumbing solution.

Post time: May-30-2025