Plumbing systems have come a long way, but not all materials meet today’s sustainability standards. The PPR stop valve stands out as a game-changer. It combines durability with eco-friendly properties, making it ideal for modern plumbing. Its ability to resist corrosion ensures long-lasting performance while promoting energy efficiency and water quality.

Key Takeaways

- PPR stop valves are strong and good for the environment. They are perfect for today’s plumbing systems.

- They don’t rust, so they last over 50 years. This means you won’t need to replace them often.

- Putting in PPR stop valves is simple and cheap. It helps save time and money on plumbing work.

Understanding the Role of PPR Stop Valves

What Is a PPR Stop Valve?

A PPR stop valve is a plumbing component designed to control the flow of water in pipelines. Made from Polypropylene Random Copolymer (PP-R), it offers durability, corrosion resistance, and eco-friendly properties. Unlike traditional valves, it’s lightweight and easy to install, making it a popular choice for modern plumbing systems.

Its technical specifications highlight its versatility. For instance:

| Specification | Details |

|---|---|

| Material Properties | Green building material, PP-R raw material composed of carbon and hydrogen. |

| Installation | Hot melt connection for quick and reliable installation. |

| Thermal Insulation | Thermal conductivity coefficient of 0.24W/m·k, minimal heat loss. |

| Weight and Strength | Specific gravity is 1/8 of steel, high strength, good toughness. |

| Applications | Used in water supply, drainage, gas, power, and agricultural irrigation. |

These features make PPR stop valves ideal for residential, commercial, and industrial applications.

Importance of Stop Valves in Plumbing Systems

Stop valves play a critical role in maintaining the efficiency and safety of plumbing systems. They regulate water flow, prevent leaks, and ensure consistent pressure levels. Without them, plumbing systems would face frequent disruptions and costly repairs.

Key benefits include:

- Preventing leaks to avoid water damage and mold growth.

- Reducing water bills by stopping unnecessary wastage.

- Ensuring system integrity and safety, especially in high-pressure situations.

For example, brass stop valves are known for their ability to handle high-pressure scenarios, optimizing system efficiency and preventing damage. Similarly, PPR stop valves offer added advantages like corrosion resistance and a longer lifespan, making them a reliable choice for sustainable plumbing systems.

Key Advantages of PPR Stop Valves

Corrosion Resistance and Longevity

One of the standout features of PPR stop valves is their exceptional resistance to corrosion. Unlike traditional metal valves, which can rust or degrade over time, PPR stop valves are made from Polypropylene Random Copolymer (PP-R). This material resists chemical reactions and electrochemical corrosion, ensuring long-lasting performance even in challenging environments.

Laboratory tests have demonstrated the durability of these valves. Here’s a quick overview:

| Attribute | Description |

|---|---|

| Non-toxic | No heavy metal additives, preventing contamination. |

| Corrosion Resistant | Resists chemical matters and electrochemical corrosion. |

| Long Life | Expected service life of over 50 years under normal conditions. |

With a lifespan exceeding 50 years under standard conditions, PPR stop valves provide a reliable solution for both residential and commercial plumbing systems. Their longevity reduces the need for frequent replacements, saving time and resources.

Eco-Friendly and Sustainable Design

Sustainability is a growing concern in modern plumbing, and PPR stop valves address this need effectively. These valves are made from non-toxic materials, ensuring they don’t release harmful substances into the water supply. This makes them safe for use in drinking water systems.

Additionally, the production process of PPR stop valves supports environmental responsibility. The materials can be recycled, reducing waste and conserving resources. Even the manufacturing waste is repurposed, minimizing the environmental footprint. By choosing PPR stop valves, users contribute to a greener future while enjoying a high-performing product.

Cost-Effectiveness and Energy Efficiency

While PPR stop valves may require a slightly higher initial investment, their long-term benefits far outweigh the upfront cost. Here’s why they’re a cost-effective choice:

- Their durability and longevity mean fewer replacements and repairs, lowering maintenance expenses.

- The lightweight design reduces shipping and handling costs.

- Excellent thermal insulation minimizes heat loss, improving energy efficiency in hot water systems.

These features make PPR stop valves an economical option for homeowners and businesses alike. Over time, the savings on maintenance and energy bills add up, making them a smart investment.

Lightweight and Easy Installation

Installing a PPR stop valve is a hassle-free process. Thanks to its lightweight design, handling and transporting these valves is much easier compared to traditional metal alternatives. This reduces labor costs and speeds up installation.

The hot melt and electrofusion connection methods ensure a secure and leak-proof fit. In fact, the joint strength often surpasses that of the pipe itself, providing added reliability. Whether for residential or industrial use, the ease of installation makes PPR stop valves a preferred choice for plumbers and contractors.

Applications of PPR Stop Valves

Residential Plumbing Systems

PPR stop valves are a perfect fit for residential plumbing systems. They help homeowners control water flow efficiently, whether it’s for sinks, showers, or toilets. Their corrosion-resistant material ensures clean water delivery without contamination. This makes them ideal for both cold and hot water pipelines.

In homes, these valves also shine in energy efficiency. Their excellent thermal insulation keeps hot water hot and cold water cold, reducing energy loss. This feature is especially useful in households with water heaters, as it helps maintain consistent temperatures. Plus, their lightweight design makes installation quick and hassle-free, saving time and labor costs.

For families concerned about safety, PPR stop valves offer peace of mind. Their non-toxic material ensures water remains safe for drinking and everyday use. With a lifespan of over 50 years, they provide a long-term solution for residential plumbing needs.

Commercial and Industrial Use

In commercial and industrial settings, PPR stop valves play a vital role in maintaining system efficiency. Their ability to handle high-pressure and high-temperature conditions makes them a reliable choice for various applications. From water supply systems to heating networks, these valves deliver consistent performance.

Here’s a closer look at their applications:

| Application Type | Description |

|---|---|

| Water Supply Systems | Efficiently controls water flow, essential for opening and closing supply to sinks and toilets. |

| Heating Systems | Regulates hot water flow to radiators and underfloor heating, leveraging heat resistance. |

| Industrial Usage | Controls flow of chemicals and fluids, with corrosion-resistant properties for durability. |

Their corrosion resistance ensures durability, even in environments where chemicals or harsh substances are present. This makes them a go-to option for industries like manufacturing and chemical processing. Additionally, their lightweight design simplifies installation in large-scale projects, reducing labor costs and downtime.

Businesses also benefit from the cost-effectiveness of PPR stop valves. Their long lifespan and minimal maintenance requirements translate to significant savings over time. Whether it’s a commercial building or an industrial plant, these valves provide a sustainable and efficient solution.

Agricultural and Irrigation Systems

PPR stop valves are also widely used in agriculture and irrigation. Farmers rely on these valves to control water flow in irrigation pipelines, ensuring crops receive the right amount of water. Their resistance to corrosion and chemicals makes them suitable for use with fertilizers and other agricultural solutions.

In irrigation systems, these valves help conserve water by preventing leaks and ensuring precise flow control. This is especially important in areas where water resources are limited. Their lightweight design makes them easy to install in large fields, while their durability ensures they can withstand outdoor conditions for years.

For greenhouse irrigation, PPR stop valves are an excellent choice. They maintain consistent water pressure, which is crucial for delicate plants. Their non-toxic material also ensures that water remains safe for crops, promoting healthy growth.

Choosing the Right PPR Stop Valve

Compatibility with Plumbing Systems

Selecting the right PPR stop valve starts with ensuring it fits your plumbing system. A mismatch can lead to inefficiencies or even system failures. To make the right choice, consider these key factors:

| Compatibility Factor | Description |

|---|---|

| Size | Ensure that the size of the valve matches the size of the pipes it connects to. |

| Pressure and Temperature | Check the pressure and temperature requirements of your system to avoid overloading the valve. |

| Application-Specific Features | Look for features like handle types or reinforced designs based on your specific application. |

For example, a residential system might need a smaller valve, while industrial setups often require larger, reinforced options. By assessing these factors, users can ensure seamless integration and optimal performance.

Regulatory Standards and Certifications

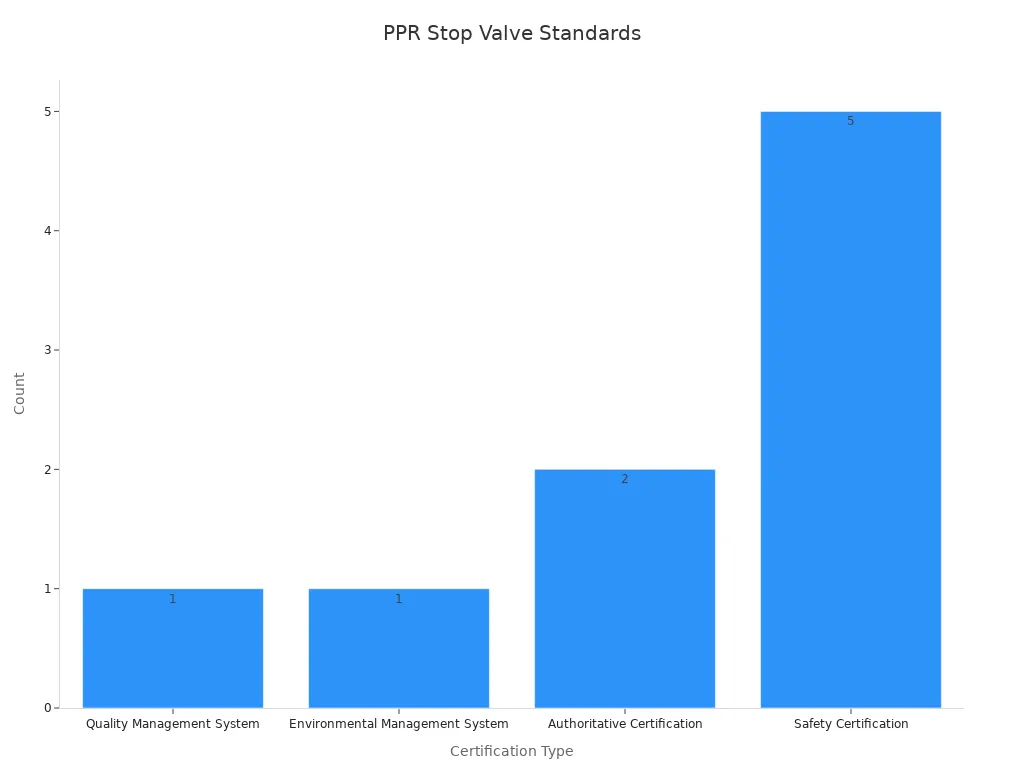

When choosing a PPR stop valve, certifications matter. They confirm the product meets safety and quality standards. Reputable valves often carry certifications from recognized bodies, such as ISO or CE. These certifications guarantee the valve’s reliability and compliance with global standards.

Here’s a quick look at some common certifications:

| Certification Body | Certification Type |

|---|---|

| ISO9001 | Quality Management System |

| ISO14001 | Environmental Management System |

| CE | Safety Certification |

| TUV | Authoritative Certification |

Choosing a certified valve ensures safety, durability, and peace of mind. It’s a small step that makes a big difference.

Size and Pressure Considerations

The size and pressure rating of a PPR stop valve are critical for its performance. A valve that’s too small or weak for the system can cause leaks or failures. Always match the valve size to the pipe diameter and check the pressure rating to ensure it can handle the system’s demands.

For high-pressure systems, reinforced valves are a must. They prevent damage and maintain efficiency. On the other hand, low-pressure systems can use standard valves, which are more cost-effective. By considering these factors, users can avoid costly repairs and ensure long-term reliability.

Maintenance Tips for PPR Stop Valves

Routine Cleaning and Inspection

Keeping a PPR stop valve in top condition doesn’t require much effort, but regular care goes a long way. Routine cleaning and inspection help prevent minor issues from turning into costly repairs.

Start by checking the valve for any visible signs of wear or damage. Look for cracks, leaks, or discoloration around the joints. If you spot any buildup, such as mineral deposits or dirt, clean it off using a soft cloth and mild detergent. Avoid abrasive cleaners, as they can damage the valve’s surface.

It’s also a good idea to test the valve’s functionality. Turn it on and off to ensure it operates smoothly. If it feels stiff or difficult to turn, applying a small amount of food-grade lubricant can help. Regular inspections like these can extend the valve’s lifespan and keep your plumbing system running efficiently.

Tip: Schedule inspections every six months to catch potential problems early.

Ensuring Long-Term Performance

To maximize the lifespan of a PPR stop valve, proper maintenance is key. One of the most important steps is to avoid exposing the valve to extreme conditions. For example, ensure the water pressure and temperature stay within the recommended range. This prevents unnecessary stress on the valve.

Another helpful practice is flushing the plumbing system periodically. This removes debris or sediment that could clog the valve over time. If the valve is part of a hot water system, insulating the pipes can also help maintain consistent temperatures and reduce wear.

Finally, always follow the manufacturer’s guidelines for maintenance. These instructions are tailored to the specific design and material of the valve, ensuring optimal performance. By taking these simple steps, users can enjoy the reliability and efficiency of their PPR stop valve for decades.

PPR stop valves stand out as the ultimate solution for sustainable plumbing. Their durability ensures long-term reliability, while their eco-friendly design supports environmental responsibility. These valves work seamlessly across residential, commercial, and agricultural systems. With low maintenance needs and cost-saving benefits, they’re a smart choice for anyone looking to upgrade their plumbing systems.

FAQ

What makes PPR stop valves better than traditional metal valves?

PPR stop valves resist corrosion, last longer, and are eco-friendly. Their lightweight design also makes installation easier compared to heavy metal valves.

Post time: May-28-2025