DN800 Injection Molded Elbow Manufacturer in China - Quality & Durability

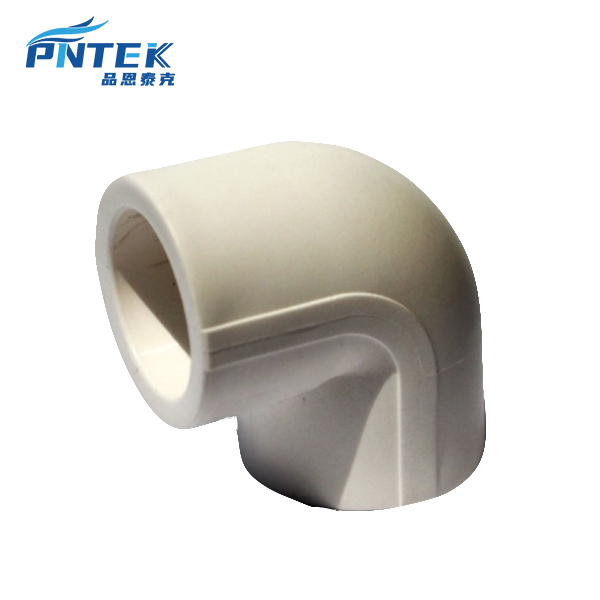

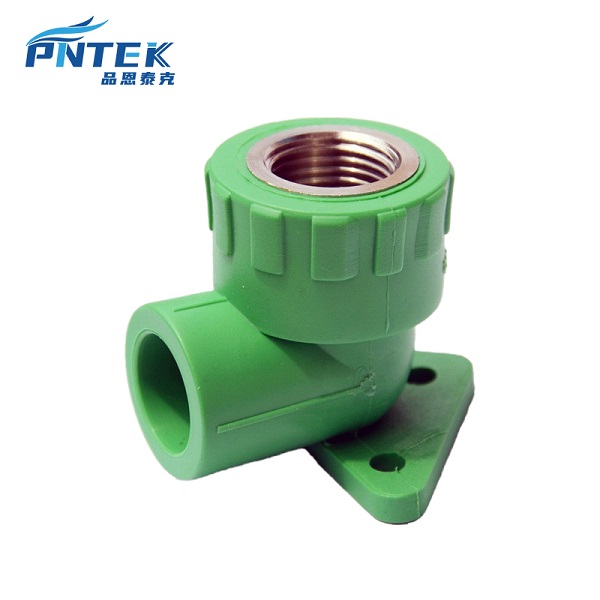

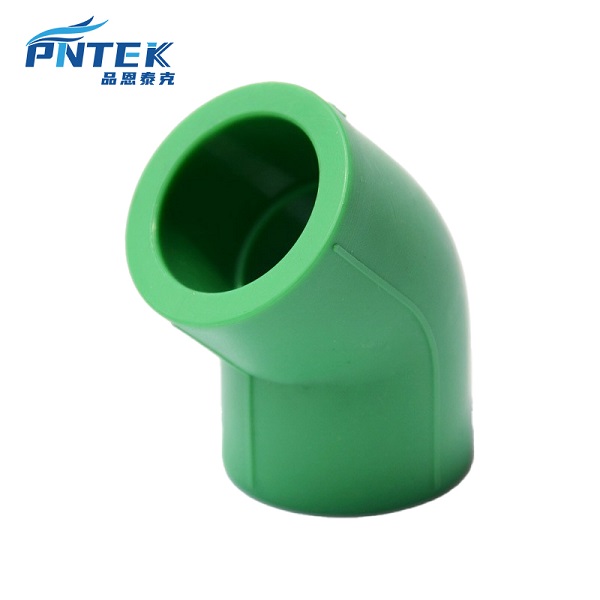

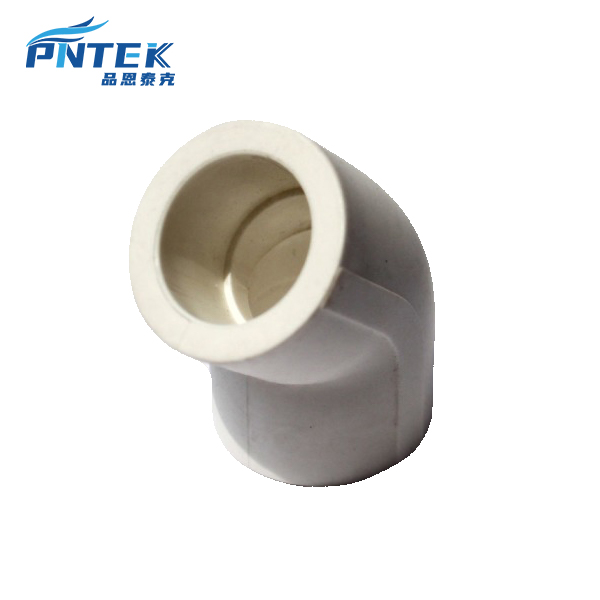

When I first came across the DN800 Injection Molded Elbow, I knew it was a game-changer for pipe fittings. This product stands out due to its robust construction and precise engineering, making it ideal for demanding industrial applications. As a professional in this space, I've seen how this elbow seamlessly fits into various systems, ensuring optimal flow and durability. Manufactured in China, this elbow combines quality and affordability, catering to businesses looking to enhance their operations without breaking the bank. I appreciate how the injection molding process provides a consistent and reliable design, reducing the potential for leaks and failures. Whether you're updating your infrastructure or starting a new project, opting for the DN800 Injection Molded Elbow from a trusted manufacturer is a smart choice. This product not only meets industry standards but also exceeds expectations, making it a valuable addition to any B2B purchaser’s lineup.

DN800 Injection Molded Elbow Manufacturer Pioneers in the Field

In the realm of industrial manufacturing, the demand for high-quality components is paramount, particularly in the field of piping systems. Among these, the DN800 injection molded elbow stands out as a critical product that enhances the efficiency and reliability of various systems. This innovative component is crafted using advanced injection molding techniques, ensuring precision, durability, and a perfect fit for any installation. Manufacturers who prioritize the use of cutting-edge technology and materials not only improve product performance but also contribute to a sustainable and efficient manufacturing process. As global procurement becomes increasingly competitive, sourcing reliable suppliers who can meet stringent quality and delivery requirements is essential. An enlightened approach to choosing a manufacturer involves looking for those who not only have a proven track record but also possess expertise in executing orders in a timely manner while maintaining exceptional standards. The importance of partnerships with quality-focused manufacturers cannot be overstated, as they play a vital role in the success and longevity of industrial projects. Furthermore, as industries strive toward greater sustainability, embracing products that are designed for extended life cycles and reduced environmental impact is crucial. Injection molded elbows, particularly those made from high-grade materials, offer not only the necessary mechanical strength but also resistance to corrosion and wear. This positions them as a superior choice for various applications, from water supply and drainage to gas distribution systems. Ultimately, selecting a leading manufacturer for these components can significantly enhance operational performance and open doors to new market opportunities worldwide.

DN800 Injection Molded Elbow Manufacturer Pioneers in the Field

| Feature | Details |

|---|---|

| Material Used | Polypropylene (PP), PVC |

| Manufacturing Process | Injection Molding |

| Size Options | DN50, DN100, DN150, DN200, DN800 |

| Applications | Water Supply, Chemical Transportation, HVAC |

| Standards Compliance | ISO 9001, ASTM Standards |

| Temperature Resistance | -20°C to 60°C |

| Connection Type | Socket Weld, Butt Weld |

| Warranty Period | 5 Years |

Related Products