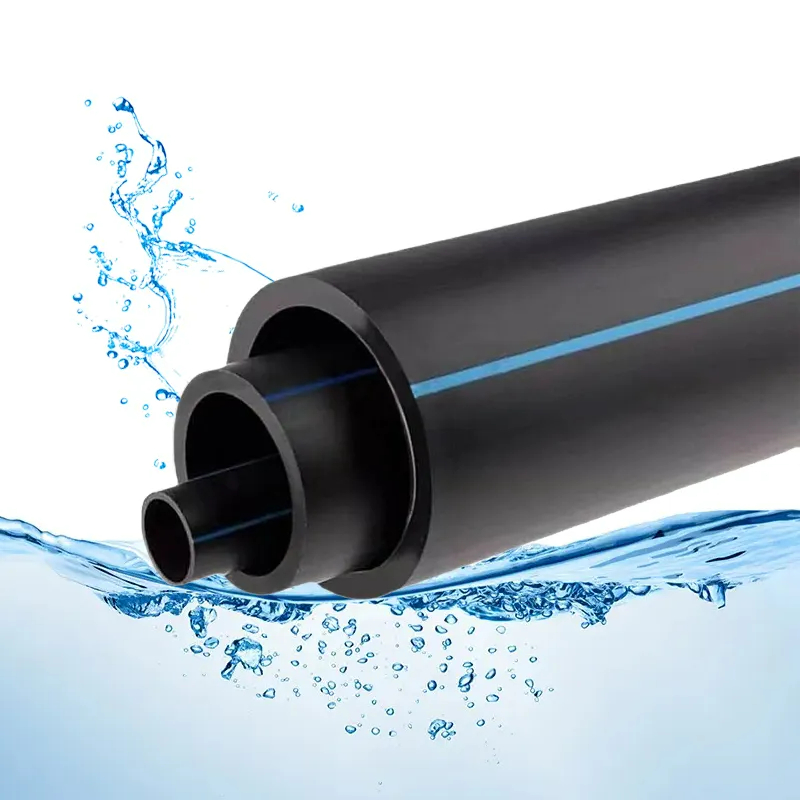

Top China Manufacturer of HDPE Stress Relief Joints for Optimal Performance

I specialize in providing top-quality HDPE Stress Relief Joints tailored for diverse industrial applications. Our products are designed with durability and performance in mind, ensuring that stress is effectively managed within your piping systems. As a leading manufacturer in China, I understand the unique demands of various sectors and prioritize your needs when crafting these essential components. Each joint is engineered to withstand harsh conditions while prolonging the lifespan of your systems, giving you peace of mind. We focus on quality assurance throughout the production process, so you can trust that you’re getting reliable, high-performance solutions. With competitive pricing and exceptional customer service, my goal is to help you find the right solutions for your projects. If you’re aiming for efficiency and longevity in your operations, our HDPE Stress Relief Joints are the smart choice. Let me help you elevate your production standards today!

HDPE Stress Relief Joint Industry Leaders From Concept to Delivery

The global demand for high-density polyethylene (HDPE) stress relief joints has been steadily increasing, driven by industries needing reliable and efficient solutions for their piping systems. As a specialized solution, HDPE stress relief joints are crucial in mitigating the stresses that arise from thermal expansions, contractions, and other dynamic factors in pipelines. By implementing these joints, companies can enhance the longevity and safety of their systems, ensuring operational efficiency while minimizing the risk of costly downtime. Innovative designs and manufacturing processes have positioned industry leaders to deliver exceptional HDPE stress relief joints that not only meet international standards but also cater to specific application needs. From conceptualization to delivery, these leaders embody a commitment to quality, utilizing advanced materials and cutting-edge technology to produce joints that enhance performance and durability. With a focus on sustainability, the industry's advancements contribute to environmentally friendly practices, aligning with the increasing demand for responsible sourcing in global procurement. Collaboration between manufacturers, engineers, and procurement professionals is essential for optimizing supply chain efficiency. As businesses continue to seek out high-quality HDPE stress relief joints, establishing strategic partnerships with reliable providers can significantly impact project success. Embracing innovation and understanding market trends will empower procurement leaders to make informed decisions that enhance their operational capabilities and drive forward-looking solutions in the ever-evolving industrial landscape.

HDPE Stress Relief Joint Industry Leaders From Concept to Delivery

| Joint Type | Material | Applications | Temperature Range (°C) | Pressure Rating (psi) |

|---|---|---|---|---|

| Butt Fusion | HDPE | Water Supply, Gas Distribution | -40 to 60 | 200 |

| Electrofusion | HDPE | Sewage Systems, Oil & Gas | -30 to 50 | 150 |

| Mechanical Joint | HDPE | Irrigation, Drainage | -20 to 50 | 100 |

| Socket Fusion | HDPE | Chemical Transfer, Industrial | -30 to 60 | 175 |

Related Products