China Manufacturer of Rubber Expansion Joints with PE Ends

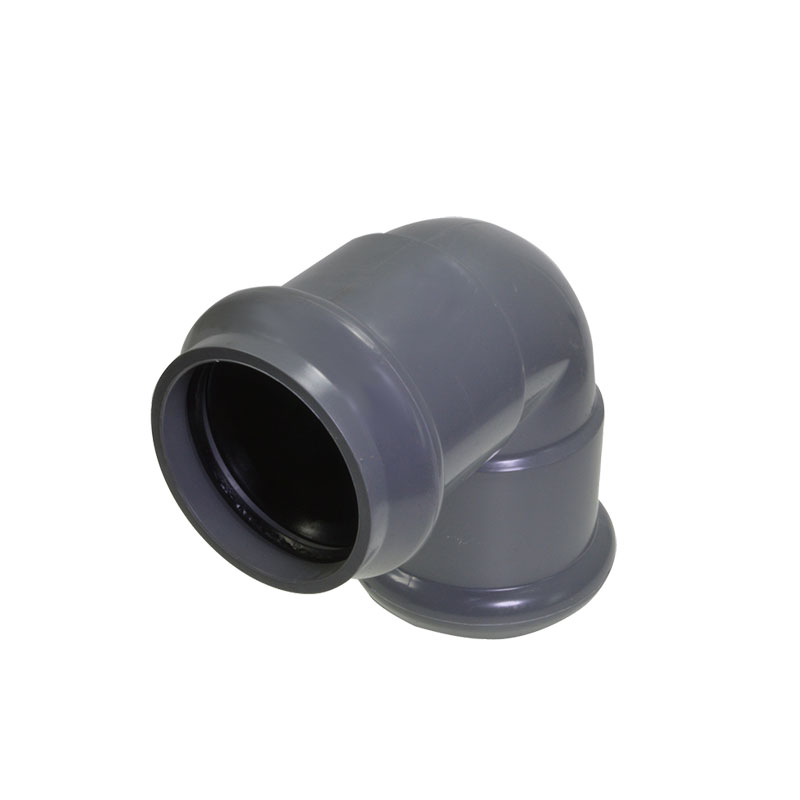

When it comes to managing industrial needs, choosing the right components is crucial. Our Rubber Expansion Joints with PE ends are designed to absorb vibrations and thermal movements in various piping systems. As a manufacturer based in China, we pride ourselves on delivering high-quality products that meet international standards. These expansion joints provide excellent flexibility and durability, ensuring the longevity of your system. They're perfect for applications in chemical processing, water treatment, and HVAC systems. Knowing that every project is unique, we offer customization options to suit your specific requirements. With our competitive pricing and reliable supply chain, we are here to support you in achieving operational efficiency. Whether you are replacing existing joints or planning a new installation, our Rubber Expansion Joints will exceed your expectations. Let's work together to ensure your projects succeed with the best solutions available!

Rubber Expansion Joint PE ends Application From Concept to Delivery

Rubber expansion joints are essential components in various industrial applications, offering flexibility and vibration absorption in piping systems. As industries worldwide strive for efficiency and reliability, the demand for high-quality expansion joints with PE ends is on the rise. These joints are designed to accommodate thermal expansion, contraction, and misalignment, ensuring the longevity and integrity of piping systems. The journey from concept to delivery of rubber expansion joints involves meticulous design, rigorous testing, and quality control. Engineers utilize advanced materials and manufacturing techniques to create joints that can withstand high pressures and extreme temperatures while maintaining flexibility. This process ensures that each product not only meets but exceeds industry standards, providing peace of mind to global buyers. Furthermore, effective inventory management and streamlined logistics are crucial, enabling timely delivery to meet the dynamic needs of various sectors around the world, including construction, oil and gas, and wastewater treatment. In conclusion, investing in rubber expansion joints with PE ends is a strategic decision for companies looking to enhance their operational efficiency. By prioritizing quality and reliability in every phase—concept to delivery—businesses are better equipped to manage their piping systems effectively. This focus not only aids in reducing maintenance costs but also bolsters overall system performance, ensuring that industrial operations can run smoothly and without interruption.

Rubber Expansion Joint PE ends Application From Concept to Delivery

| Application Area | Material Type | Size Range (inches) | Temperature Range (°C) | Pressure Rating (psi) | Delivery Time (weeks) |

|---|---|---|---|---|---|

| Water Treatment | EPDM | 2 - 24 | -10 to 80 | 150 | 4 |

| Chemical Processing | Nitrile | 3 - 30 | -20 to 100 | 200 | 6 |

| HVAC Systems | Silicone | 4 - 36 | -30 to 200 | 300 | 5 |

| Oil and Gas | Fluoroelastomer | 1 - 20 | -15 to 150 | 250 | 8 |

| Food Industry | Natural Rubber | 1 - 12 | 0 to 90 | 100 | 3 |

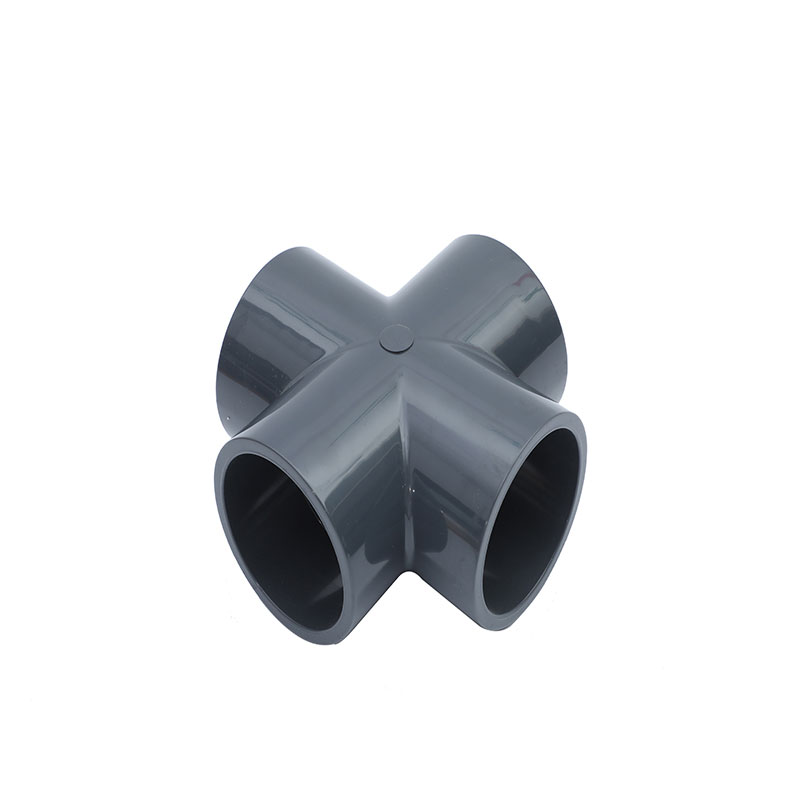

Related Products