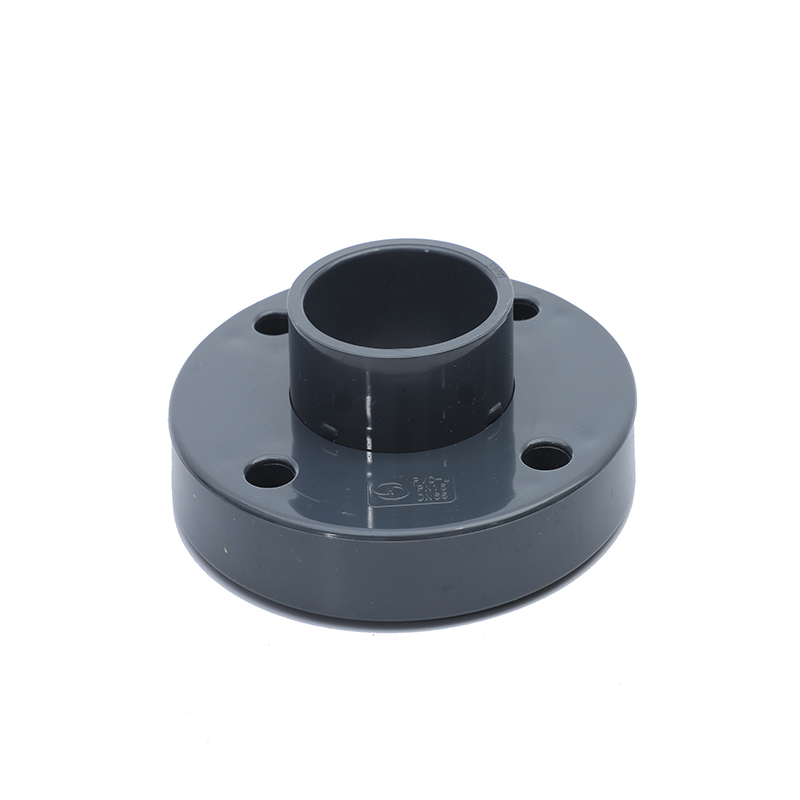

China Manufacturer of Stub End HDPE Flange - Quality & Durability

When it comes to reliable connections in your piping system, our Stub End HDPE Flange stands out as a top choice. Manufactured in China, we focus on quality and durability, ensuring each piece meets industry standards. It’s perfect for various applications, including water supply and drainage, making it a versatile addition to any project. I've seen firsthand how these flanges are engineered for easy installation and provide a secure fit. Plus, working directly with us as the manufacturer means you can expect competitive pricing and personalized support. We understand the unique needs of our B2B partners and aim to build lasting relationships. With our Stub End HDPE Flange, you can trust that you're getting a product designed to perform under pressure, no matter the environment. Let's enhance your operations and ensure efficiency together!

Stub End Hdpe Flange Application Your End-to-End Solution

Stub End HDPE flanges have become increasingly popular in various industries due to their unique properties and advantages. These components are particularly suited for applications requiring high resistance to corrosion, chemicals, and environmental stress. As an end-to-end solution for fluid transport systems, HDPE flanges ensure a secure, leak-proof connection that can withstand rigorous conditions, making them ideal for use in sectors such as water treatment, petrochemical, and construction. The installation of Stub End HDPE flanges streamlines the joining process, allowing for effortless maintenance and reduced downtime. Their lightweight nature simplifies handling and installation, making them a cost-effective choice for global procurement. Moreover, these flanges offer flexibility in design and application, accommodating a variety of piping configurations to meet the specific needs of any project. While selecting the right flanges for your project, consider the advantages of using HDPE materials, including longevity, resistance to harsh environments, and compliance with industry standards. By choosing Stub End HDPE flanges, you not only enhance the durability of your piping systems but also contribute to more sustainable development practices, as HDPE is fully recyclable. This versatile solution can ultimately minimize lifecycle costs and improve operational efficiency for your business.

Stub End HDPE Flange Application Your End-to-End Solution

| Application Area | Material Type | Connection Method | Temperature Range (°C) | Pressure Rating (PSI) |

|---|---|---|---|---|

| Water Supply Systems | HDPE | Socket Fusion | 0 to 40 | 160 |

| Wastewater Treatment | HDPE | Electrofusion | 0 to 50 | 150 |

| Irrigation Systems | HDPE | Flanged | 0 to 60 | 130 |

| Chemical Processing | HDPE | Socket Fusion | -40 to 60 | 100 |

Related Products