DIN Standard HDPE Bend Manufacturer in China | Quality Solutions

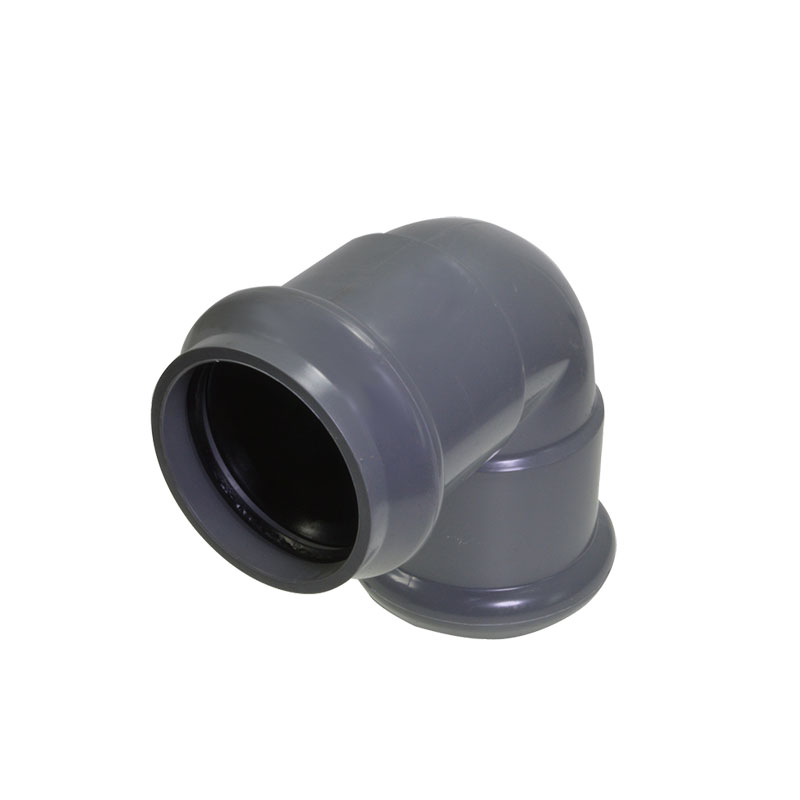

When I think of high-quality fittings for various applications, the DIN Standard HDPE Bend immediately comes to mind. Made from durable high-density polyethylene, these bends are perfect for ensuring seamless transitions in piping systems. As a manufacturer based in China, I take pride in offering top-notch products that meet international standards. Our HDPE bends not only provide excellent resistance to corrosion and chemicals but also contribute to the longevity of your installations. Whether you're in construction, water treatment, or other industrial sectors, our bends are designed to improve flow and efficiency. I understand the importance of reliability in your projects, and that’s why we ensure our products undergo rigorous quality checks before they reach you. Partnering with us means you get exceptional service and quality at competitive prices. Let’s enhance your operations with our proven DIN Standard HDPE Bend solutions!

DIN Standard HDPE Bend Market Leader For the Current Year

In the ever-evolving landscape of industrial materials, the DIN Standard HDPE bend has emerged as a crucial component for various applications, from construction to manufacturing. Recognized for its durability and flexibility, HDPE (high-density polyethylene) is not only resistant to environmental stressors but also offers unparalleled longevity. This makes it a preferred choice among global procurement professionals looking to optimize both performance and cost-effectiveness in their projects. As businesses strive for operational efficiency, sourcing high-quality HDPE bends that meet stringent DIN standards is essential. These standards ensure that the products are reliable, safe, and capable of withstanding the rigors of daily use. By aligning procurement strategies with trusted suppliers, companies can secure a competitive edge, ensuring their projects run smoothly while adhering to international quality norms. For procurement specialists, understanding the market dynamics of HDPE bends can significantly influence purchasing decisions. Buyers are encouraged to assess product specifications, supplier capabilities, and market trends to make informed choices. Investing in reliable and compliant HDPE products not only enhances project outcomes but also contributes to sustainable practices, setting the stage for long-term success in an increasingly competitive market.

DIN Standard HDPE Bend Market Leader For the Current Year

| Dimension (mm) | Bend Radius (mm) | Material Thickness (mm) | Weight (kg) | Application |

|---|---|---|---|---|

| 90 x 90 | 180 | 6 | 1.5 | Water Supply |

| 110 x 110 | 220 | 8 | 2.0 | Drainage |

| 160 x 160 | 320 | 10 | 3.5 | Sewage |

| 200 x 200 | 400 | 12 | 5.0 | Industrial Use |

| 250 x 250 | 500 | 14 | 7.0 | Construction |

Related Products