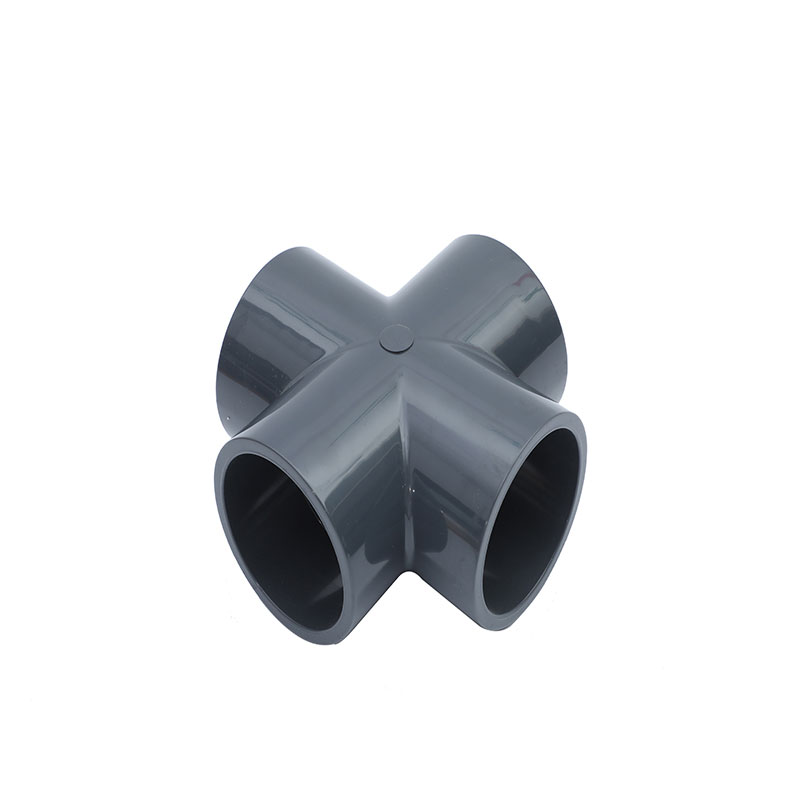

Top China Manufacturer of DIN Standard HDPE Cross for Durable Solutions

When it comes to DIN Standard HDPE Cross fittings, quality and reliability is all that matters. As a buyer, you want products that meet international standards, and that's exactly what we offer. Sourced directly from a trusted China manufacturer, our HDPE crosses are designed to ensure optimal performance in any application. With exceptional resistance to corrosion and durability, these fittings can withstand even the most challenging environments. I know how crucial it is for you to find the right supplier, and our commitment to excellent service and competitive pricing makes us a top choice. Each HDPE cross goes through rigorous quality checks, ensuring you get only the best for your projects. Whether you’re in construction, plumbing, or any other industry, our DIN Standard HDPE Cross fittings will meet your needs perfectly. Don’t hesitate to reach out for samples or inquire about bulk orders. Quality is just a step away!

DIN Standard HDPE Cross Pioneers in the Field Sets the Industry Standard

In the ever-evolving landscape of high-density polyethylene (HDPE) products, DIN standards have emerged as a critical benchmark for quality and reliability. These standards ensure that materials meet rigorous safety, sustainability, and performance criteria, which is essential for various applications, including construction, agriculture, and infrastructure development. As industries globally prioritize eco-friendly materials, HDPE’s versatility and durability position it as a front-runner. Innovative manufacturers are leading the charge, developing cross-pioneering solutions that set new industry benchmarks and enhance operational efficiency. The shift towards using HDPE products governed by DIN standards not only assures buyers of quality but also enhances supply chain transparency. Compliance with these standards enables global procurement specialists to make informed decisions based on consistent product specifications. Moreover, manufacturers are increasingly focusing on sustainable practices, such as recycling and reduced material waste, which align with the environmental goals of many businesses today. Global procurement professionals seeking reliable partners can benefit from engaging with manufacturers who prioritize these standards, thereby ensuring their supply chains are resilient and sustainable. In conclusion, the adoption of DIN standards in HDPE manufacturing not only elevates product quality but also reinforces the commitment to sustainability and innovation within the industry. As global procurement trends shift towards accountability and environmental consideration, partners that uphold these high standards will stand out as leaders, offering superior products that meet the demands of modern markets.

DIN Standard HDPE Cross Pioneers in the Field Sets the Industry Standard

| Dimension | Material | Standard Compliance | Application Area | Industry |

|---|---|---|---|---|

| DN20 | HDPE | DIN 8074 | Water Supply | Construction |

| DN40 | HDPE | DIN 16845 | Irrigation | Agriculture |

| DN50 | HDPE | DIN 19533 | Gas Supply | Energy |

| DN80 | HDPE | DIN EN 12201 | Sewage Systems | Environmental |

| DN100 | HDPE | DIN EN 1555 | Industrial Waste | Manufacturing |

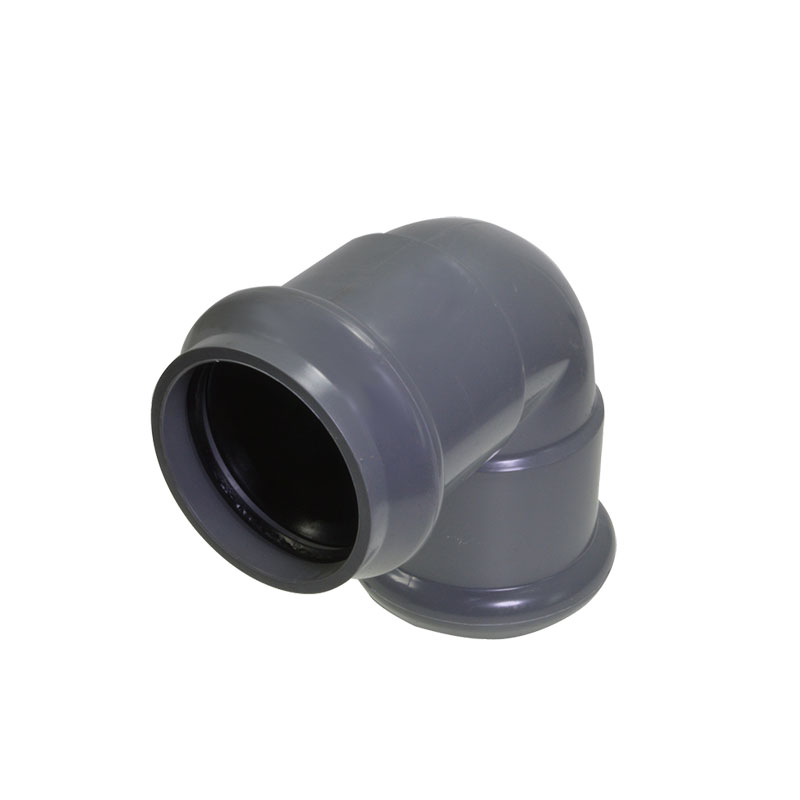

Related Products