Top China Manufacturer of Electric Ball Valve for Reliable Performance

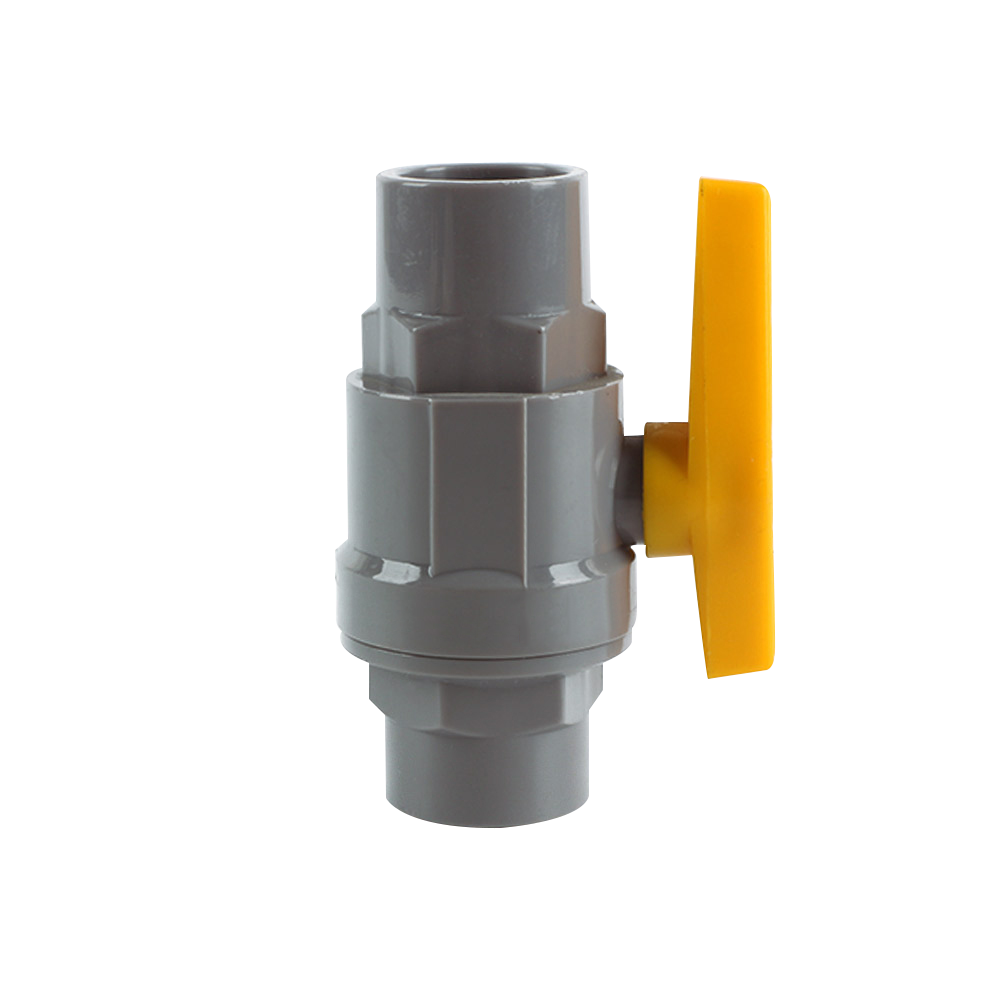

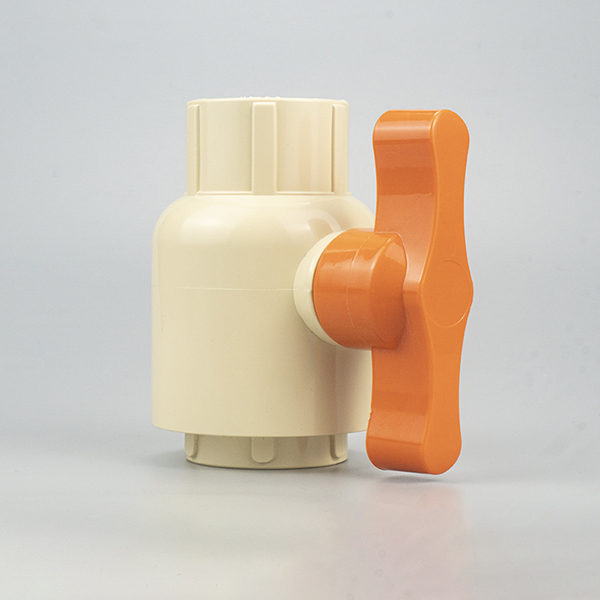

When I think of reliable solutions for fluid control, the Electric Ball Valve immediately comes to mind. As a buyer, I appreciate how these valves offer precision and efficiency, especially when sourced from a reputable manufacturer in China. The ability to seamlessly automate processes with these electric ball valves not only enhances productivity but also reduces operational costs. Whether I’m working on a manufacturing project or handling HVAC systems, I find these valves adaptable for various applications. They are designed to handle high pressures and provide excellent sealing, ensuring that there’s no leakage during operation. Plus, the ease of installation and maintenance makes them a go-to choice for many projects. By choosing a manufacturer in China, I can access a wide range of options that meet international quality standards without breaking the bank. Investing in Electric Ball Valves is a smart move that I’m confident will pay off in the long run.

Electric Ball Valve Manufacturer From Concept to Delivery

In the rapidly evolving landscape of industrial automation, electric ball valves play a pivotal role in enhancing operational efficiency and precision. From the initial concept stage to the final delivery, the process of manufacturing these critical components entails a meticulous approach tailored to meet the diverse needs of global buyers. The journey begins with innovative design practices that leverage advanced technology, ensuring not only functional reliability but also compliance with international standards. As an electric ball valve manufacturer, the focus extends beyond mere production. Rigorous quality control measures are integrated throughout the process, allowing for consistent performance and durability that can withstand varying environmental conditions. Moreover, custom solutions are offered to meet specific application requirements, highlighting the ability to adapt to the unique demands of different industries, including water treatment, HVAC, and food processing. In a world where efficiency and sustainability are paramount, the seamless integration of electric ball valves into existing systems can significantly reduce energy consumption and enhance automation capabilities. By choosing a reliable partner committed to excellence in quality and service, global purchasers can not only ensure superior product performance but also foster long-term collaboration that drives innovation and growth in their operations.

Electric Ball Valve Manufacturer From Concept to Delivery

| Phase | Description | Key Deliverables | Duration | Responsible Team |

|---|---|---|---|---|

| Concept Development | Initial brainstorming and concept sketches. | Concept sketches, specifications document. | 2 weeks | Design Team |

| Design Phase | Detailed design and engineering analysis. | 3D models, engineering drawings. | 4 weeks | Engineering Team |

| Prototyping | Creating prototypes for testing and validation. | Prototype units, testing reports. | 6 weeks | R&D Team |

| Testing & Validation | Comprehensive testing of prototypes. | Test results, compliance certifications. | 3 weeks | Quality Assurance Team |

| Production Planning | Planning the production line and logistics. | Production schedule, material lists. | 2 weeks | Operations Team |

| Manufacturing | Full-scale production of electric ball valves. | Finished products, packaging. | Variable | Manufacturing Team |

| Delivery | Shipping products to clients. | Delivery confirmation, shipping documentation. | 1 week | Logistics Team |

Related Products