Top Electric Butterfly Valve Manufacturers in China for Quality Solutions

As a seasoned professional in industrial valves, I understand the crucial role electric butterfly valves play in efficient fluid control systems. Our electric butterfly valves, crafted with precision in China, offer unmatched durability and performance. They are designed to provide quick opening and closing, making them ideal for various applications, from water treatment to HVAC systems. When it comes to reliability, I trust our products to meet the rigorous demands of any project. Each valve demonstrates energy efficiency and excellent sealing capabilities, ensuring minimal leakage and optimal flow rates. Plus, being a direct manufacturer means we can offer competitive pricing without compromising on quality. By choosing our electric butterfly valves, you’re not just purchasing a product; you’re investing in a solution that simplifies operations and enhances system efficiency. Let’s work together to elevate your processes with our top-of-the-line electric butterfly valves today!

Electric Butterfly Valve Sets the Industry Standard Manufacturers You Can Rely On

Electric butterfly valves are becoming essential in various industries due to their reliability, efficiency, and ease of use. As end-users seek solutions that not only enhance operational efficiency but also ensure safety, the need for high-quality electric butterfly valve manufacturers is more significant than ever. These valves leverage advanced technology to provide precise control over flow, making them indispensable in applications ranging from water treatment to HVAC systems. When selecting a manufacturer, global purchasers should consider several critical factors. First, the quality of materials used in valve production is paramount, as it directly impacts durability and performance. Additionally, look for manufacturers that adhere to international standards, ensuring their products meet global compliance requirements. A strong reputation within the industry often indicates reliability, making it vital to evaluate the track record of potential suppliers through customer reviews and case studies. Furthermore, innovation plays a crucial role in the electric butterfly valve sector. Companies that invest in research and development are better positioned to deliver state-of-the-art solutions, adapting to the ever-changing demands of the market. As you explore your options, consider manufacturers who not only meet current standards but also push the boundaries of technology to offer enhanced features that ensure long-term performance and value.

Electric Butterfly Valve Sets the Industry Standard Manufacturers You Can Rely On

| Manufacturer | Product Type | Key Features | Applications | Certifications |

|---|---|---|---|---|

| Manufacturer A | Electric Butterfly Valve | High durability, Leak-proof design | Water treatment, HVAC systems | ISO 9001, CE |

| Manufacturer B | Electric Butterfly Valve | Corrosion-resistant, Compact design | Chemical processing, Food industry | API 609, NSF |

| Manufacturer C | Electric Butterfly Valve | Fast response time, Energy efficient | Power plants, Oil & gas | ISO 14001, ATEX |

| Manufacturer D | Electric Butterfly Valve | Low maintenance, Easy installation | Building automation, Pharmaceuticals | UL, RoHS |

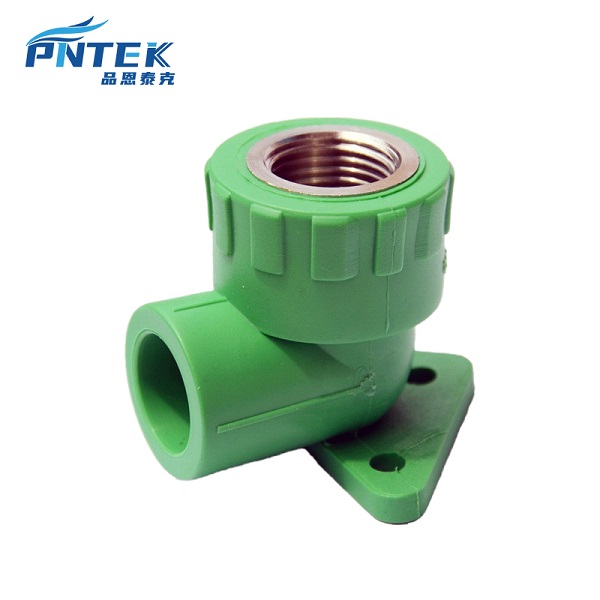

Related Products