HDPE Pressure Testing Fitting Manufacturer in China – Quality Assured

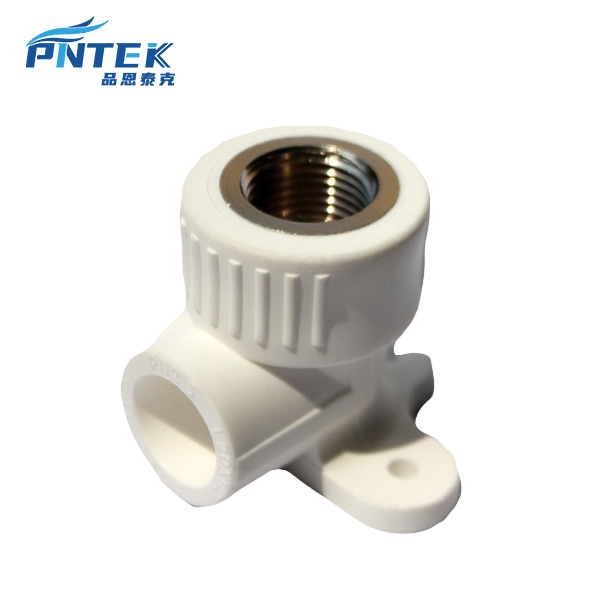

When it comes to HDPE pressure testing fittings, I understand how crucial quality and reliability are for your projects. Sourced directly from a leading manufacturer in China, these fittings are designed to withstand high-pressure applications while ensuring optimal performance. My extensive experience in the industry has shown me that the right fitting can make all the difference in your pipeline systems. Our HDPE pressure testing fittings are rigorously tested for durability and safety, providing peace of mind for all your installations. With a range of sizes and specifications, you'll find exactly what you need for your specific requirements. Investing in our fittings means you are choosing a product that not only meets international standards but also helps streamline your operations. Don't hesitate to reach out if you have any questions or need assistance with your order.

Hdpe Pressure Testing Fitting For the Current Year Exceeds Industry Benchmarks

The demand for high-quality HDPE pressure testing fittings has surged as industries strive to enhance performance and safety standards. Our latest advancements in design and manufacturing techniques have enabled us to deliver fittings that not only meet but exceed current industry benchmarks. This is crucial as businesses worldwide seek reliable solutions to ensure pipeline integrity, especially in sectors like water distribution, oil and gas, and construction. Our cutting-edge pressure testing fittings are engineered to withstand extreme conditions while providing precise measurements. With rigorous testing protocols and adherence to international standards, these products have become a trusted choice for procurement professionals. By incorporating innovative materials and technologies, we've significantly improved the durability and efficiency of our fittings, allowing for seamless integration into existing systems. As global procurement trends continue to evolve, investing in superior HDPE fittings becomes essential for operational excellence. By choosing products that surpass conventional benchmarks, companies can enhance their reliability and reduce maintenance costs over time. Embracing these advancements not only strengthens their market position but also aligns with sustainable practices, paving the way for a more resilient future in various industries.

Hdpe Pressure Testing Fitting For the Current Year Exceeds Industry Benchmarks

| Test Date | Fitting Type | Pressure (psi) | Duration (minutes) | Status |

|---|---|---|---|---|

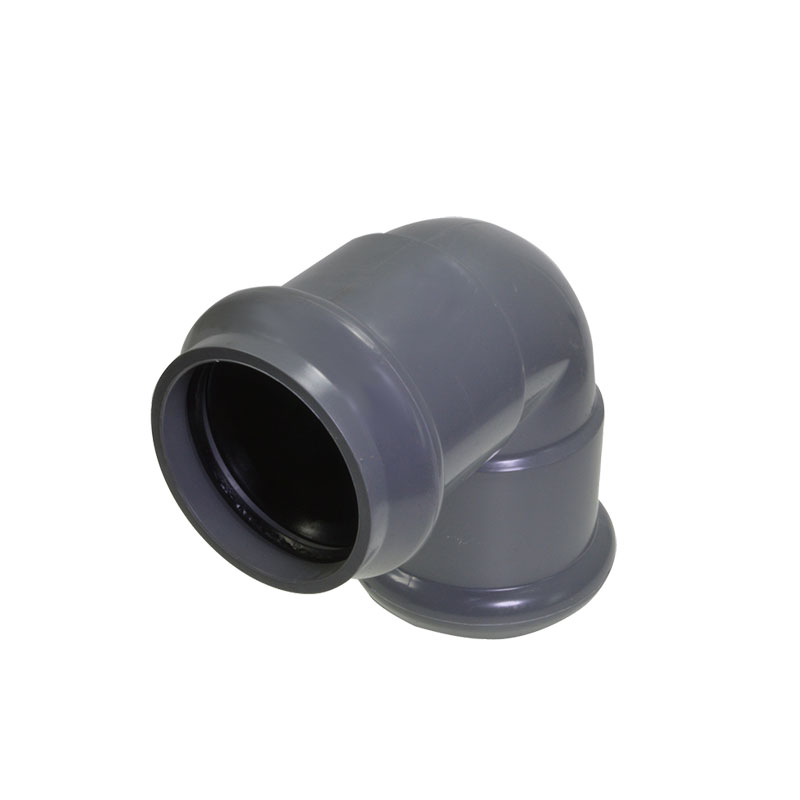

| 2023-01-15 | Elbow 90° | 150 | 30 | Passed |

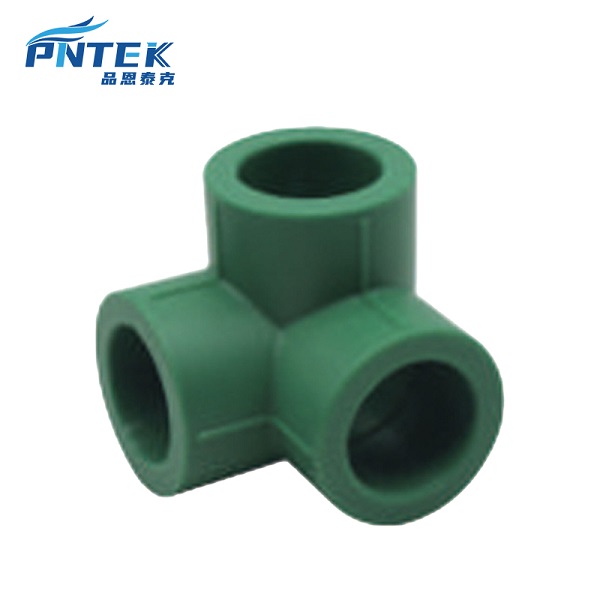

| 2023-02-10 | Tee | 160 | 45 | Passed |

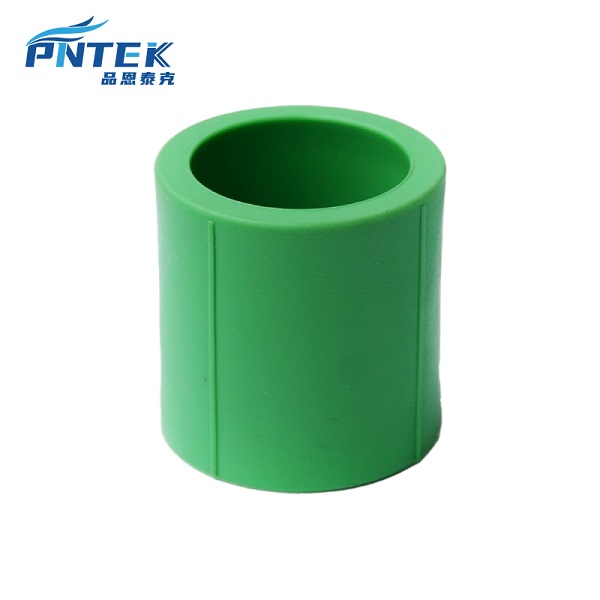

| 2023-03-22 | Coupling | 140 | 50 | Passed |

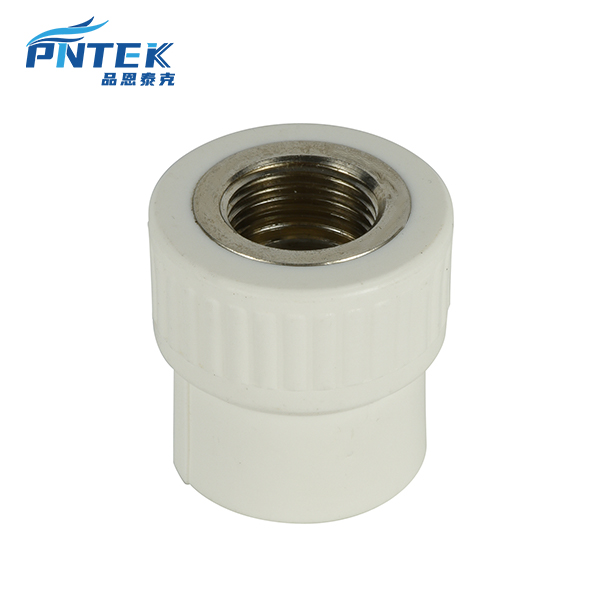

| 2023-04-05 | Cap | 170 | 60 | Passed |

| 2023-05-11 | Reducer | 155 | 40 | Passed |

Related Products