High Pressure PE Cross Manufacturer in China - Quality & Reliability

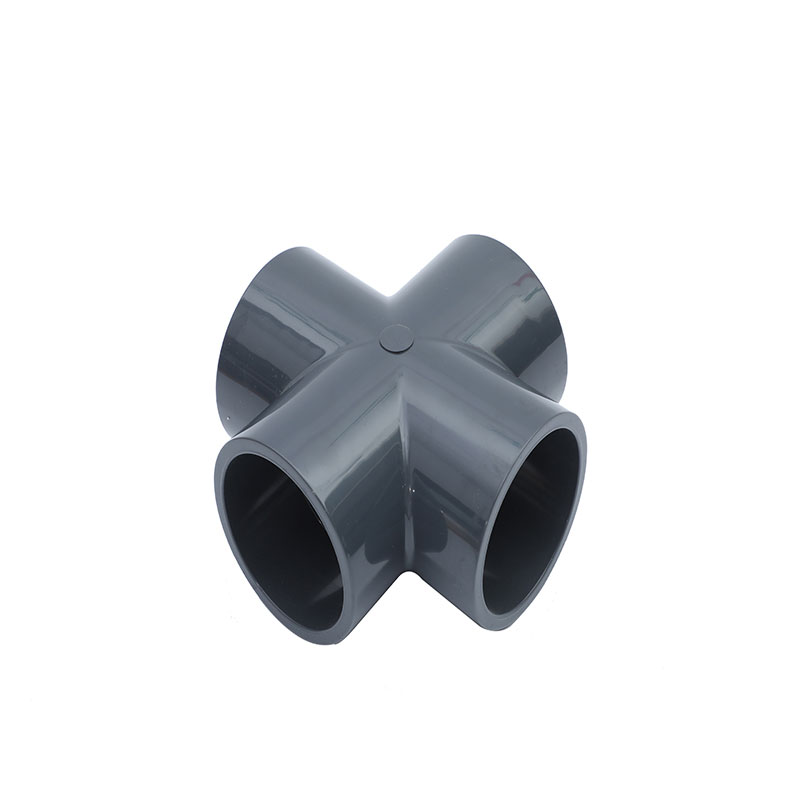

When I think about reliable and durable piping solutions, High Pressure PE Cross comes to my mind immediately. Manufactured in China, this product offers exceptional strength and resistance against harsh conditions, making it perfect for various applications. With its unique design, it ensures seamless connections, significantly reducing the risk of leaks and failures in high-pressure environments. As a manufacturer dedicated to quality, we prioritize using top-grade materials that not only meet industry standards but also exceed expectations. It’s essential for B2B purchasers like you to have dependable components that enhance operational efficiency. Plus, the competitive pricing we offer allows you to keep your project costs manageable while not compromising on quality. Let's work together to find the best solution for your specific needs with our High Pressure PE Cross, ensuring a long-lasting performance for your business.

High Pressure PE Cross Now Trending Where Innovation Meets 2025

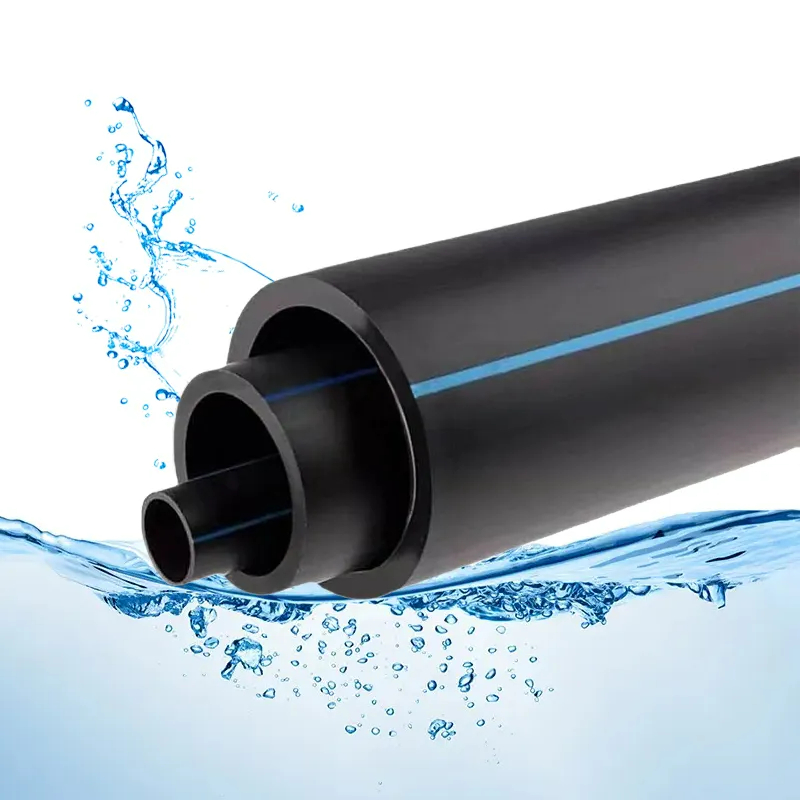

In today's rapidly evolving market, high-pressure polyethylene (PE) cross-laminated products are gaining significant traction as they blend innovation with efficiency. These advanced materials are not only durable but also versatile, making them ideal for various applications across industries such as packaging, construction, and automotive. As businesses seek sustainable solutions, high-pressure PE cross products are setting new standards, thanks to their lightweight nature and resistance to extreme conditions. As we move toward 2025, the demand for these innovative materials is expected to surge, driven by their ability to enhance product performance while minimizing environmental impact. Companies looking to optimize their supply chains and reduce costs will find high-pressure PE cross-laminated options an attractive choice. These products not only provide reliability but also support eco-friendly initiatives, aligning with the global push for sustainability that resonates with consumers and businesses alike. Investing in high-pressure PE cross technology places procurement professionals at the forefront of innovation. By integrating these materials into product lines, businesses can enhance their competitive advantage, respond to market trends, and ultimately drive growth. As the industry navigates the complexities of modern demand, embracing such breakthroughs is essential for those aiming to thrive in a dynamic marketplace.

High Pressure PE Cross Now Trending Where Innovation Meets 2025

| Dimension (mm) | Tensile Strength (MPa) | Density (g/cm³) | Temperature Resistance (°C) | Applications |

|---|---|---|---|---|

| 25 x 25 | 60 | 0.95 | 80 | Agriculture |

| 32 x 32 | 65 | 0.94 | 75 | Irrigation |

| 50 x 50 | 70 | 0.96 | 90 | Industrial Use |

| 40 x 40 | 75 | 0.93 | 85 | Construction |

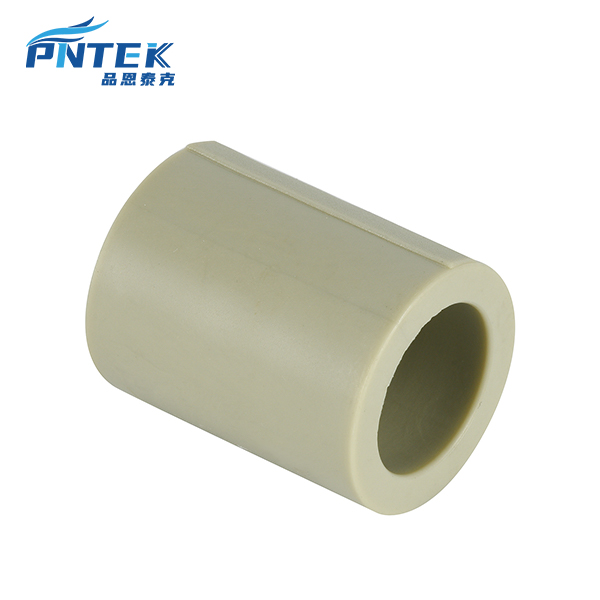

Related Products

OEM High Quality140MM 160MM 168MM 200MM Stainless Steel UPVC Big Size Ball Valve For Project DN200

Read More