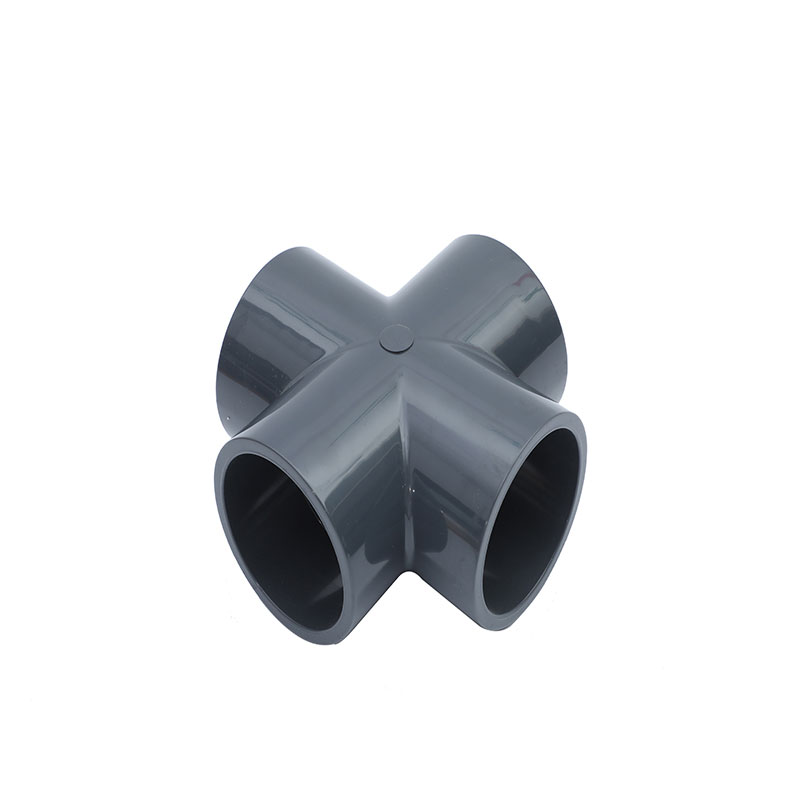

Injection Molded PE Cross Manufacturer in China for Quality Solutions

Are you in need of high-quality Injection Molded PE Cross? I understand how crucial it is to find reliable products that meet your specifications, especially when sourcing from manufacturers in China. Our Injection Molded PE Cross is designed for durability and versatility, making it perfect for various applications in your industry. I’ve seen firsthand how these cross pieces can enhance the performance of your projects, ensuring a strong connection with minimal risk of failure. Working with a trusted manufacturer in China means you not only get competitive pricing but also consistent quality assurance. Whether you’re in construction, plumbing, or another sector, our Injection Molded PE Cross can help streamline your operations while providing the reliability you need. Let's take your business to the next level together with products that stand the test of time. Reach out to discuss how we can meet your specific requirements!

Injection Molded PE Cross in 2025 Exceeds Industry Benchmarks

In recent trends, the injection molded PE cross has emerged as a game-changer in various industries, showing remarkable performance that exceeds established industry benchmarks for 2025. This innovation directly addresses the growing demand for durable, lightweight, and cost-effective solutions in diverse applications, ranging from construction to automotive manufacturing. As global suppliers seek high-quality materials that meet stringent operational standards, the injection molded PE cross stands out for its superior strength, flexibility, and resistance to environmental factors. The efficiency of injection molding technology in producing these components not only enhances manufacturing processes but also reduces waste and energy consumption. With the industry moving towards sustainability, the advantages of using polyethylene (PE) are notably significant. This material is not only recyclable but also offers a longer lifespan compared to traditional alternatives, making it an attractive option for conscientious manufacturers looking to optimize their supply chains while adhering to eco-friendly practices. As we look ahead to 2025 and beyond, procurement professionals and global buyers must consider the injection molded PE cross as a pivotal element in their sourcing strategies. With its unmatched quality and reliability, this product enables businesses to improve their operational efficiencies and maintain a competitive edge in an ever-evolving marketplace. Embracing such innovations will be crucial for those aiming to thrive in the future landscape of manufacturing.

Injection Molded PE Cross in 2025 Exceeds Industry Benchmarks

| Dimension | 2023 Benchmark | 2025 Projection | Percentage Change |

|---|---|---|---|

| Production Rate (units/day) | 500 | 650 | 30% |

| Material Cost ($/kg) | 2.00 | 1.80 | -10% |

| Defect Rate (%) | 4.5 | 2.0 | -55% |

| Energy Consumption (kWh/unit) | 1.2 | 0.95 | -20.83% |

| Lead Time (days) | 14 | 10 | -28.57% |

Related Products