China Manufacturer of Pe Electrofusion Fittings for Quality Connections

When it comes to robust and reliable piping solutions, Pe Electrofusion Fittings are your best choice. I’ve been in the industry for years, and I can confidently say these fittings are a game-changer in connections, especially in HDPE applications. Manufactured in China, our products maintain stringent quality standards, ensuring durability and resistance to harsh conditions. The electrofusion process guarantees a seamless bond, reducing the risk of leaks and failures, making it ideal for various sectors like water, gas, and industrial applications. As a manufacturer, we prioritize precision in our products, so you can trust us to deliver fittings that meet your specific requirements. By choosing our Pe Electrofusion Fittings, you’re investing in long-term performance and peace of mind. Let's connect and take your projects to the next level with our innovative solutions tailored for modern needs. Don’t miss out on the opportunity to enhance your pipeline infrastructure!

Pe Electrofusion Fittings in 2025 Pioneers in the Field

As we approach 2025, the demand for innovative solutions in piping systems is on the rise, particularly in the realm of PE electrofusion fittings. These advanced connections have revolutionized the way industries approach plastic piping systems, offering unparalleled reliability and performance. With the global market expanding, it is crucial for procurement professionals to stay informed about the latest trends and developments in this sector. The evolution of PE electrofusion technology has greatly enhanced the installation and longevity of piping systems, especially in environments requiring stringent safety standards. These fittings allow for seamless integration, which not only minimizes the risk of leaks but also streamlines the installation process, providing significant cost savings over time. As we move forward, innovations in materials and manufacturing will only enhance these benefits, making electrofusion fittings even more appealing to global buyers who prioritize efficiency and sustainability in their projects. In the quest for sustainable resource management, the adaptability of PE electrofusion fittings is noteworthy. They are suitable for various applications, including water supply, gas distribution, and industrial processes, aligning perfectly with the growing emphasis on eco-friendly solutions. As we look to the future, the focus will be on enhancing product performance while ensuring minimal environmental impact, paving the way for a new era in piping technology. Procurement leaders must adapt to these changes to leverage the advantages that come with adopting cutting-edge solutions in their supply chains.

Pe Electrofusion Fittings in 2025 Pioneers in the Field

| Category | Material | Standard | Applications | Features |

|---|---|---|---|---|

| Electrofusion Coupling | Polyethylene | ISO 4427 | Gas and Water Distribution | Durable, Corrosion Resistant |

| Electrofusion Saddle | Polyethylene | ASTM D2513 | Tap Installations | Easy Installation, Reliable Connection |

| Electrofusion Tee | Polyethylene | EN 12201 | Industrial and Residential | High Strength, Pressure Safe |

| Electrofusion End Cap | Polyethylene | AS/NZS 4130 | Pipe Termination | Leak Resistant, Long-lasting |

| Electrofusion Reducer | Polyethylene | DIN 8074 | Flow Transition | Flexible Application, Cost-effective |

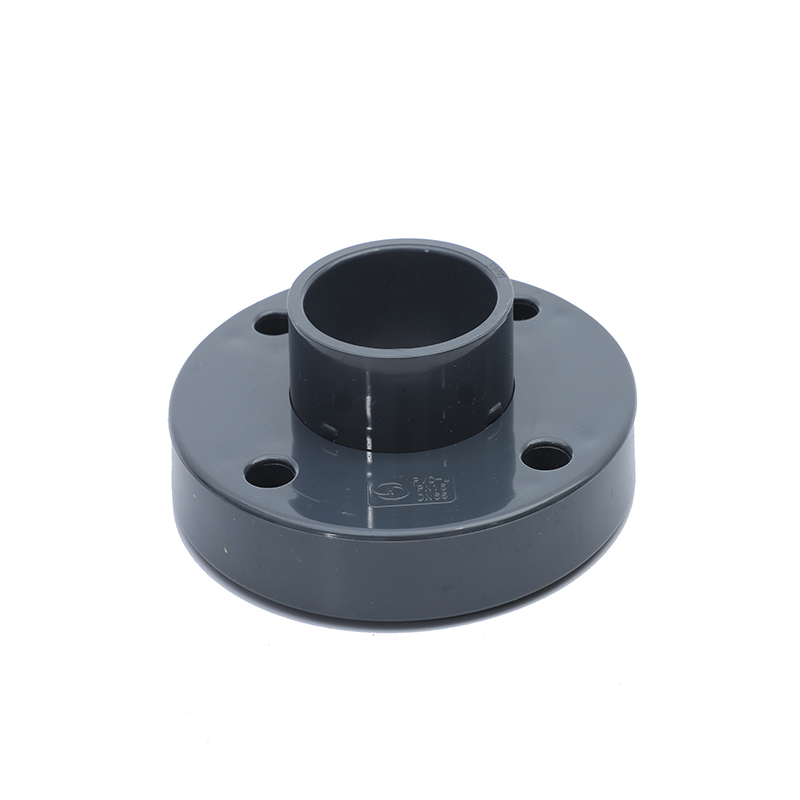

Related Products