Quality Plastic Ball Valve Dn50 from Leading China Manufacturer

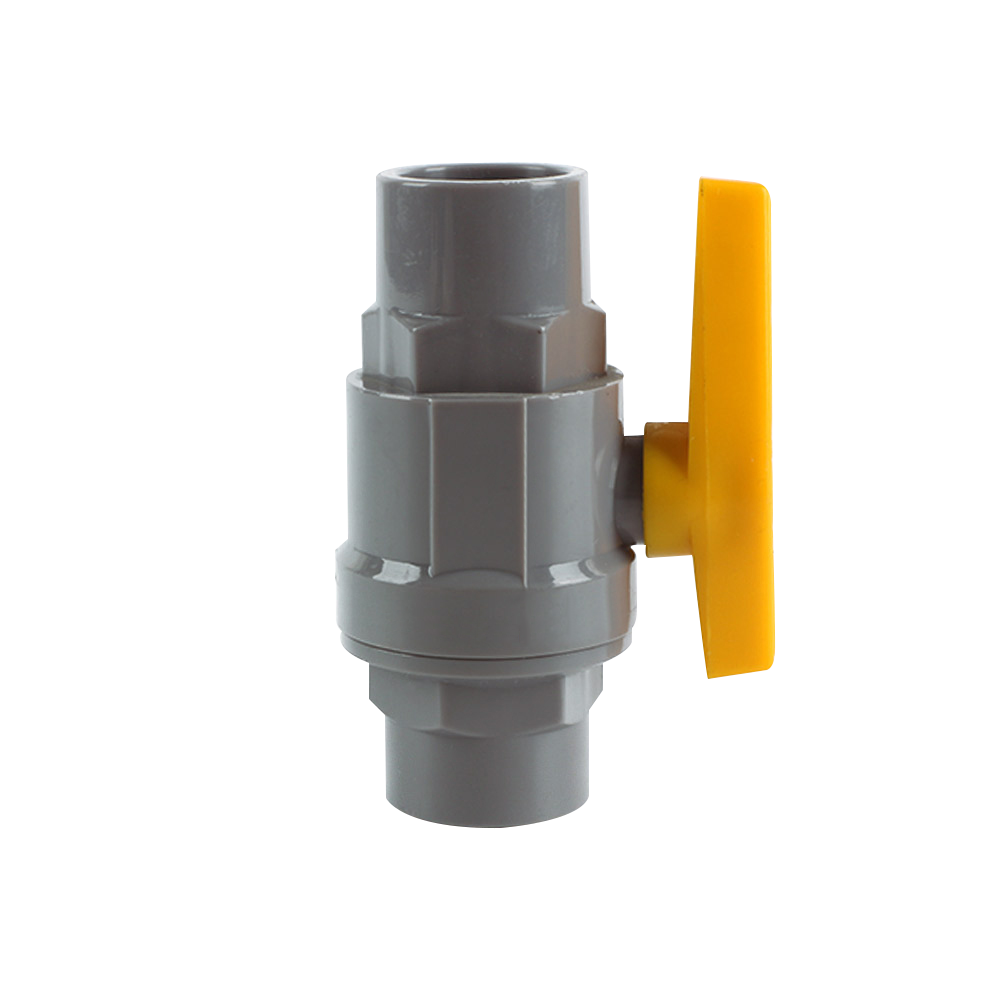

When I think about reliable performance in fluid control, the Plastic Ball Valve Dn50 stands out. Crafted for durability and efficiency, this valve is perfect for a range of applications, especially in industrial settings. Our product is manufactured in China, ensuring top-notch quality that meets various industry standards. With its robust plastic body, it offers excellent resistance to corrosion, making it ideal for aggressive fluids. I understand the importance of sourcing the right components for your projects, and this valve’s easy installation and maintenance will save you valuable time. Whether you're a small business or a large manufacturer, investing in our Plastic Ball Valve Dn50 means choosing reliability and performance. Don’t hesitate to reach out to me for more details on how our manufacturing capabilities can meet your needs. You’ll find that working with a trusted supplier makes all the difference in project execution!

Plastic Ball Valve Dn50 Service From Concept to Delivery

When it comes to achieving seamless operations in fluid management, the choice of valve plays a crucial role. Our focus on the plastic ball valve DN50 exemplifies our commitment to delivering high-quality solutions from concept to delivery. Designed with precision and engineered for durability, this valve meets the rigorous demands of various industrial applications, providing effective and reliable service even under challenging conditions. Our comprehensive service approach ensures that every step, from the initial design phase to the final delivery of the product, is meticulously executed. By collaborating closely with clients, we can tailor solutions to meet specific needs, ensuring optimal performance and efficiency. The use of high-grade materials in the manufacturing process further enhances the durability and corrosion resistance of our plastic ball valves, making them ideal for a plethora of environments. In an increasingly competitive global market, the emphasis on quality and efficiency cannot be overstated. Our commitment to excellence not only guarantees performance but also fosters long-lasting partnerships with our clients. With a robust supply chain and a focus on innovation, we are equipped to meet your procurement needs, ensuring that each plastic ball valve DN50 not only meets but exceeds your expectations.

Plastic Ball Valve Dn50 Service From Concept to Delivery

| Service Stage | Description | Duration | Responsible Team | Quality Control Method |

|---|---|---|---|---|

| Concept Development | Initial design concepts and specifications | 2 Weeks | Design Team | Concept Review Meetings |

| Prototyping | Creating prototypes for testing functionality | 3 Weeks | Engineering Team | Prototype Testing & Feedback |

| Production Planning | Finalizing production processes and materials | 1 Week | Production Team | Planning Review Sessions |

| Manufacturing | Manufacturing of the ball valve | 4 Weeks | Manufacturing Team | In-Process Quality Inspections |

| Delivery | Shipping the finished product to the client | 1 Week | Logistics Team | Shipping Document Verification |

Related Products