China Manufacturer of Plastic PPR Pipe Fitting Mould for Quality Solutions

If you’re in the market for reliable plastic PPR pipe fitting moulds, I can help you find what you need. As a China-based manufacturer, we specialize in producing high-quality moulds that meet the demands of various industries. Our products are designed with precision to ensure optimal performance and durability, so you can trust them for your projects. I understand that sourcing the right mould can be a challenge, but with our extensive experience and commitment to excellence, we deliver solutions that enhance your production efficiency. Each mould we manufacture undergoes strict quality control to ensure it meets industry standards. Plus, we offer customized options to suit your specific requirements. Partnering with us means getting access to innovative designs and competitive pricing. Let's elevate your business together with our top-notch plastic PPR pipe fitting moulds that stand the test of time. Reach out to learn more about how we can support your manufacturing needs!

Plastic Ppr Pipe Fitting Mould Service Backed by Expertise From Concept to Delivery

In today's competitive market, the efficiency and reliability of plastic PPR pipe fitting molds are paramount for manufacturers looking to streamline production and enhance product quality. Our comprehensive mold service is designed to cater to your specific needs, starting from the initial concept all the way through to the final delivery. With our wealth of expertise, we ensure that every mold is engineered with precision to meet international standards, enhancing your production capabilities while reducing lead times. Our team of skilled professionals leverages advanced technology and industry insights to design molds that not only fulfill your functionality requirements but also optimize production efficiency. By closely collaborating with our clients throughout the process, we ensure that each stage reflects your unique specifications and market demands. This commitment to excellence not only improves product performance but also contributes to cost-effective manufacturing, allowing you to focus on expanding your business. Choosing our mold service means investing in a partnership that prioritizes your success. We recognize the importance of timely delivery and quality assurance, providing you with confidence in your supply chain. As a global supplier, we are dedicated to helping you navigate the complexities of production while delivering exceptional results that stand out in the marketplace. Let us support you in achieving your business goals with our tailor-made PPR pipe fitting mold solutions.

Plastic Ppr Pipe Fitting Mould Service Backed by Expertise From Concept to Delivery

| Service Feature | Description | Benefits | Expertise Level |

|---|---|---|---|

| Design Consultation | Collaborative design sessions to finalize specifications | Tailored solutions for unique requirements | Advanced |

| Prototyping | Creation of initial molds for testing | Early feedback on design viability | Intermediate |

| Mold Production | Manufacturing of high precision molds | High efficiency and reduced production time | Expert |

| Quality Assurance | Rigorous testing of molds and fittings | Ensures high standards and reliability | Expert |

| Delivery and Support | Timely delivery along with ongoing support | Customer satisfaction and hassle-free experience | Advanced |

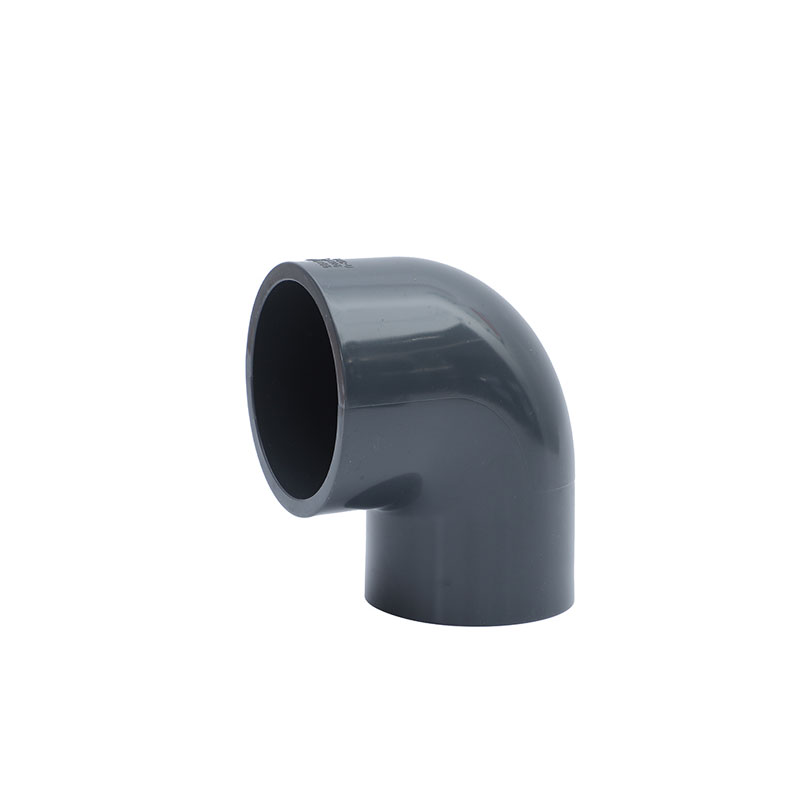

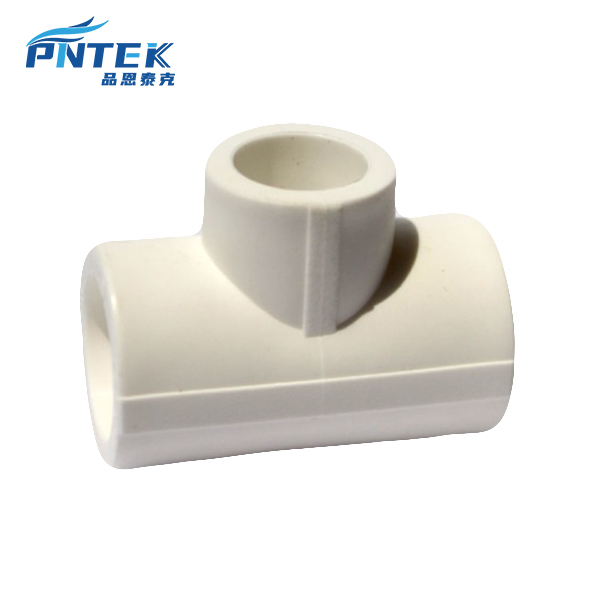

Related Products