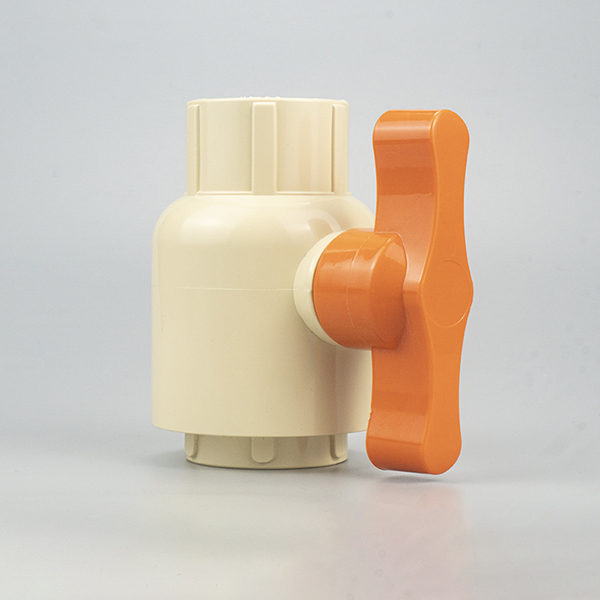

Plastic Union Valve from Leading China Manufacturer - Quality & Reliability

As a manufacturer based in China, I’m excited to share our high-quality Plastic Union Valve that meets a variety of industrial needs. This valve, crafted from durable materials, ensures reliable performance while remaining lightweight and corrosion-resistant. Ideal for both water and chemical applications, it offers easy installation with its user-friendly design. Having worked closely with clients across different sectors, I understand the importance of efficiency and reliability in operations. Our Plastic Union Valves stand out due to their exceptional sealing capabilities and long lifespan, helping you reduce maintenance costs in the long run. We take pride in our stringent quality control processes, ensuring that every valve leaving our facility meets high standards. When you choose our product, you’re not just getting a valve; you’re investing in peace of mind. Let’s take your projects to the next level with our trusted Plastic Union Valve—where quality meets affordability!

Plastic Union Valve Service Industry Giant

In the rapidly evolving landscape of the manufacturing and service industries, the plastic union valve sector is experiencing significant growth, driven by rising global demand for durable, reliable solutions. As businesses across various sectors seek to optimize their operations, the critical role of high-quality plastic union valves cannot be understated. These components are essential for ensuring seamless fluid transfer in applications ranging from agriculture to chemical processing, highlighting the need for industry giants that can provide robust products and services. The advantages of plastic union valves are numerous, including their resistance to corrosion, lightweight nature, and easy installation and maintenance. This makes them an ideal choice for industries that require both efficiency and longevity in their piping systems. As global procurement managers search for competitive suppliers, understanding the intricacies of the plastic union valve market becomes essential. Factors such as material selection, design innovations, and adherence to international quality standards play crucial roles in supplier differentiation. Working with a trusted provider in the plastic union valve service industry means not just securing a product but gaining a partnership that facilitates growth and innovation. As the market expands, the focus on sustainability and cost-effectiveness is driving refinements in manufacturing processes and supply chains. By leveraging advanced technologies and materials science, manufacturers are poised to meet the evolving needs of industries worldwide, ensuring that the future of fluid management is as efficient and sustainable as possible.

Plastic Union Valve Service Industry Giant

| Product Type | Material | Size (mm) | Connection Type | Pressure Rating (psi) | Application |

|---|---|---|---|---|---|

| Ball Valve | PVC | 20 | Socket | 150 | Water Supply |

| Butterfly Valve | CPVC | 50 | Flanged | 200 | Chemical Handling |

| Gate Valve | PP | 100 | Threaded | 300 | Slurry Transfer |

| Check Valve | PVC | 25 | Socket | 150 | Backflow Prevention |

| Pressure Relief Valve | HDPE | 30 | Flanged | 150 | Pressure Control |

Related Products