PN16 Rubber Bellows PE Manufacturer in China - Quality & Durability

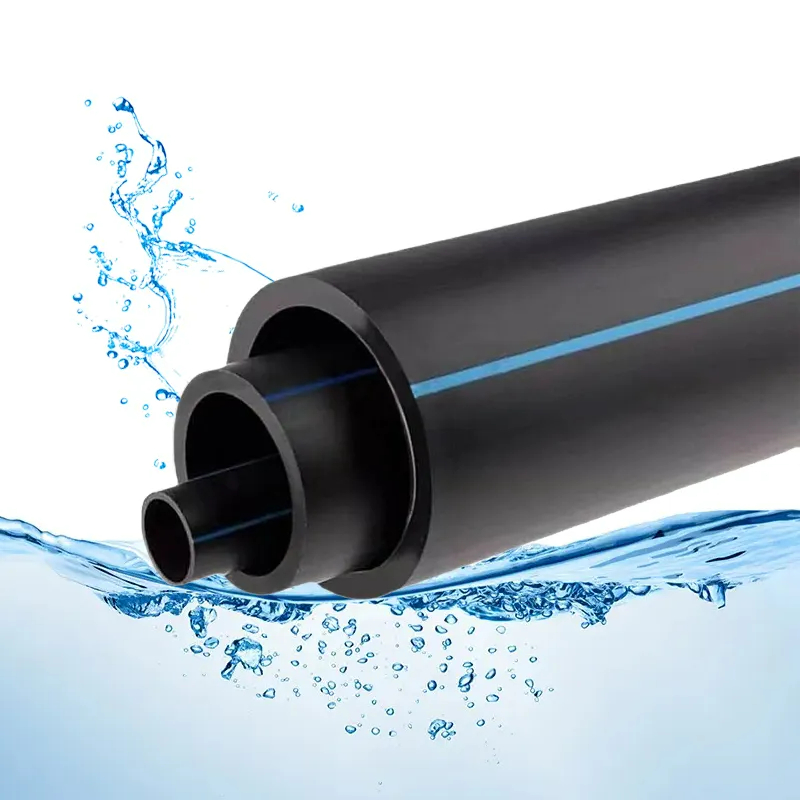

When I think about the essential components for industrial applications, PN16 Rubber Bellows PE stands out. These high-quality bellows are designed to withstand pressure and offer reliable performance, making them perfect for various industries. Sourced directly from leading manufacturers in China, I can assure you that the quality is top-notch and meets international standards. Whether you’re in the automotive or construction sector, these bellows provide the flexibility and durability needed to manage movements and shocks in piping systems. The rubber material ensures long-lasting usage, reducing the need for frequent replacements. With my vast experience in sourcing, I’ve seen how investing in these bellows can greatly enhance operational efficiency while minimizing downtime. If you’re interested in reliable components that can withstand the test of time, PN16 Rubber Bellows PE from a trusted China manufacturer is definitely the way to go.

PN16 Rubber Bellows PE Now Trending Supplies the World\u2019s Top Brands

In today's rapidly evolving manufacturing landscape, the demand for high-quality rubber bellows, particularly the PN16 models, has surged, positioning them as essential components in various applications. These flexible, durable, and versatile products not only provide protection against contaminants but also enhance the performance and longevity of machinery across diverse industries. With a trend towards globalization, manufacturers are sourcing these supplies from leading experts who understand the nuances of quality and compliance with international standards. The global marketplace now requires suppliers to maintain consistency in product excellence, catering to the needs of top brands across sectors such as automotive, aerospace, and industrial equipment. The PN16 rubber bellows are designed to withstand challenging environments while ensuring optimal functionality. As businesses seek reliable partners, it is crucial to collaborate with manufacturers who prioritize innovation and boast robust quality control measures. Investing in top-tier rubber bellows can significantly reduce operational costs, enhance product reliability, and ensure compliance with evolving industry regulations. As procurement professionals look for suppliers that not only deliver exceptional products but also understand the importance of customer service and rapid deployment, the spotlight shines on those who can provide comprehensive solutions tailored to specific business needs. Embracing these trends and aligning with capable manufacturers will pave the way for successful partnerships and sustainable growth in the global market.

PN16 Rubber Bellows PE Now Trending Supplies the World’s Top Brands

| Dimension | Material | Application | Certification | Usage Temperature |

|---|---|---|---|---|

| 50 mm | EPDM Rubber | Industrial Machinery | ISO 9001 | -30°C to +100°C |

| 75 mm | Nitrile Rubber | Automotive | CE Marked | -20°C to +80°C |

| 100 mm | Silicone Rubber | Food Processing | FDA Approved | -50°C to +200°C |

| 150 mm | Natural Rubber | Construction | RoHS Compliant | -10°C to +60°C |

Related Products