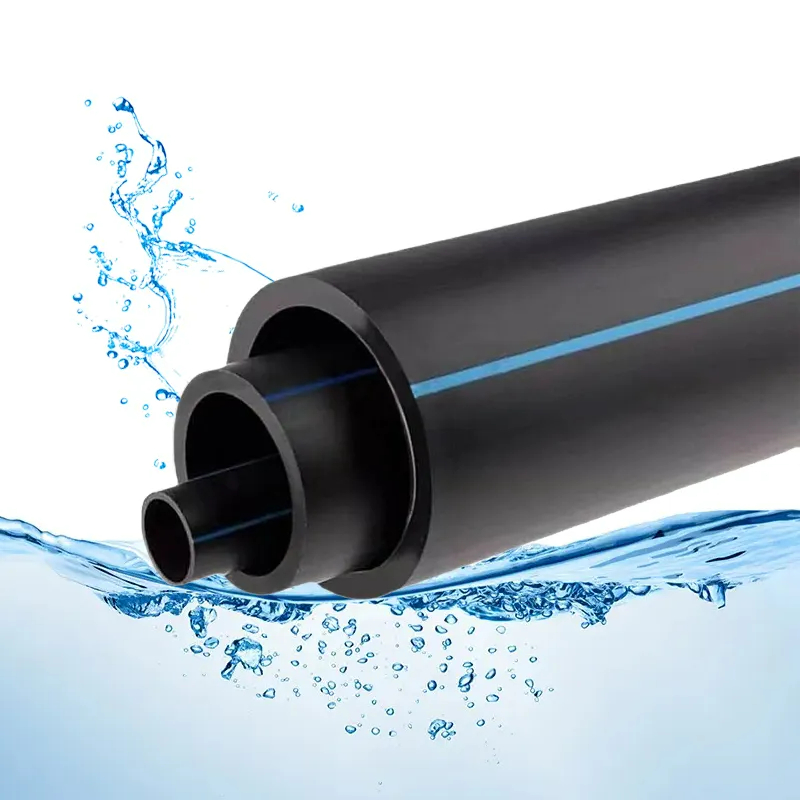

Top China Manufacturer of Polyethylene Compression Fittings

When it comes to polyethylene compression fittings, I always recommend choosing a reliable manufacturer from China. These fittings are designed for durability and efficiency in a wide range of applications, from irrigation systems to plumbing installations. As someone who has worked closely with these products, I can assure you that they provide a leak-proof seal and are easy to install, saving both time and labor costs. The versatility of these fittings makes them ideal for both residential and commercial projects. With a focus on quality, our fittings undergo rigorous testing to ensure they meet the highest standards. I also appreciate that they come in various sizes to suit different piping needs. Partnering with a trusted Chinese manufacturer means you can expect timely delivery and fair pricing without compromising on quality. If you’re looking to streamline your operations and enhance your project outcomes, consider polyethylene compression fittings as a reliable choice.

Polyethylene Compression Fitings Trusted by Pros Winning in 2025

In the ever-evolving landscape of industrial materials, polyethylene compression fittings have emerged as a preferred choice among professionals in various sectors. As we look towards 2025, the demand for high-quality, reliable fittings continues to surge, driven by advancements in technology and the need for efficient, cost-effective solutions. These fittings are not only designed for durability but also for easy installation and maintenance, making them ideal for both seasoned experts and newcomers alike. Professionals seeking reliable connectors recognize that polyethylene offers remarkable resilience against corrosion and environmental factors, ensuring longevity and consistent performance in diverse applications. The innovations in manufacturing processes have led to enhanced designs that optimize flow characteristics and minimize pressure loss, further contributing to operational efficiency. As the industry moves forward, the focus on sustainability is prompting manufacturers to enhance their offerings, ensuring that they meet the highest standards of quality while remaining environmentally friendly. As global procurement managers explore options for their projects, investing in state-of-the-art polyethylene compression fittings will undoubtedly be a strategic choice. With the right partner, businesses can secure a competitive edge by leveraging these advanced solutions, leading to improved project timelines and reduced costs. The future is bright for those who embrace these innovations, ensuring that their operations are not only efficient but also aligned with the requirements of a rapidly changing marketplace.

Polyethylene Compression Fittings Trusted by Pros Winning in 2025

| Type | Size (inches) | Material | Applications | Rating (out of 5) | Year of Release |

|---|---|---|---|---|---|

| Straight Connector | 1/2 | Polyethylene | Water Supply | 4.7 | 2023 |

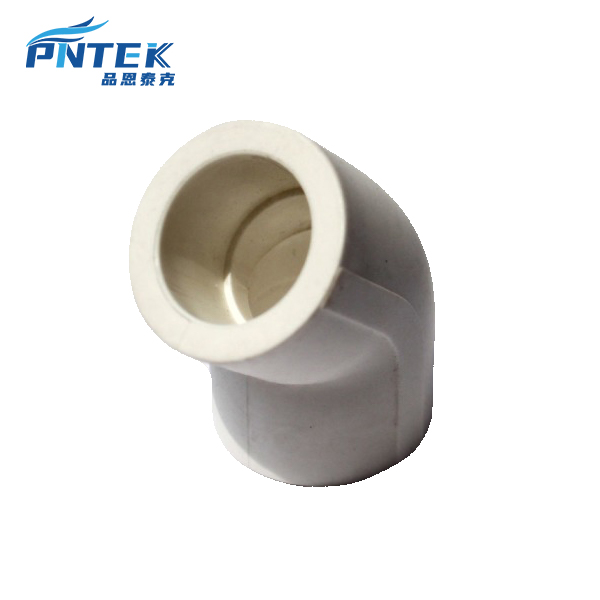

| Elbow Connector | 3/4 | Polyethylene | Irrigation | 4.5 | 2024 |

| Tee Connector | 1 | Polyethylene | Gas Lines | 4.8 | 2025 |

| Cap | 2 | Polyethylene | End of Line | 4.6 | 2023 |

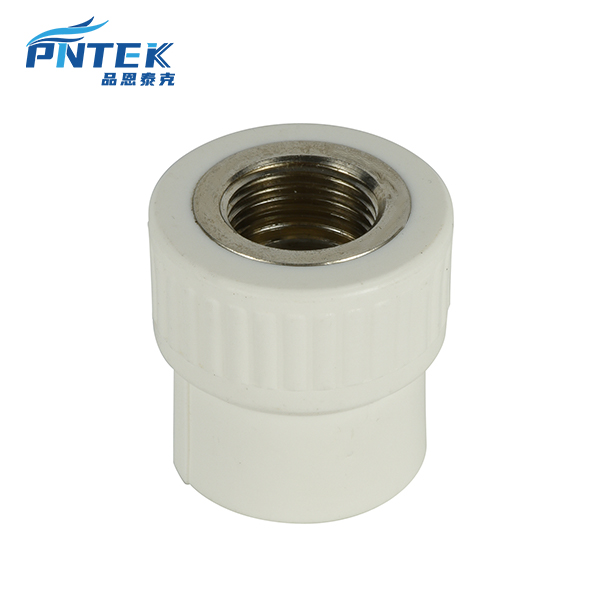

| Compression Coupling | 1/2 | Polyethylene | Pipe Joining | 4.9 | 2025 |

Related Products