High-Quality PPR Fittings Mould Manufacturer in China - Durable Solutions

When it comes to sourcing top-quality PPR fittings mould, I understand the importance of reliable options. That's why I trust the expertise of manufacturers in China, where innovation meets affordability. Each mould is designed with precision, ensuring durability and excellent performance for various applications. These PPR fittings moulds not only meet international standards but are also created with the latest technology to enhance efficiency in production. I have seen firsthand how a well-crafted mould can significantly impact the quality of the final product, reducing waste and increasing profitability. If you’re navigating the competitive landscape of plumbing supplies, investing in high-quality PPR fittings mould is a game changer. I encourage you to consider partnering with a reputable manufacturer in China to elevate your product line and meet your customers' needs effectively. Let's make your procurement process seamless and successful!

Ppr Fittings Mould Manufacturer Factory

When seeking high-quality PPR fittings, choosing the right mold manufacturer can significantly impact the efficiency and effectiveness of your production process. For global procurement specialists, understanding the capabilities and advantages of partnering with a reputable manufacturer is crucial. A well-established factory ensures that each mold is crafted with precision, utilizing advanced technologies and materials, thereby reducing production waste and enhancing the overall quality of the fittings. Moreover, a reliable manufacturer emphasizes quality control at every stage of production. With rigorous testing and inspection protocols in place, you can be assured that the final products meet international standards while supporting sustainability initiatives. Engaging with a partner that prioritizes innovation and customization allows businesses to tailor their product offerings to meet the specific demands of diverse markets, ultimately driving competitive advantage. In a rapidly evolving industry, staying ahead requires collaboration with a mold manufacturer that not only understands the technical aspects but also the market dynamics. By investing in a strong partnership, procurement professionals can leverage improved lead times, cost-effectiveness, and a comprehensive support system that aligns with their strategic goals. This holistic approach ensures that your supply chain remains robust and responsive to the ever-changing needs of your customers.

Ppr Fittings Mould Manufacturer Factory

| Mould Type | Material | Production Time (Days) | Cavities | Weight (kg) | Application |

|---|---|---|---|---|---|

| Socket Mould | Steel | 30 | 4 | 150 | Pipes & Fittings |

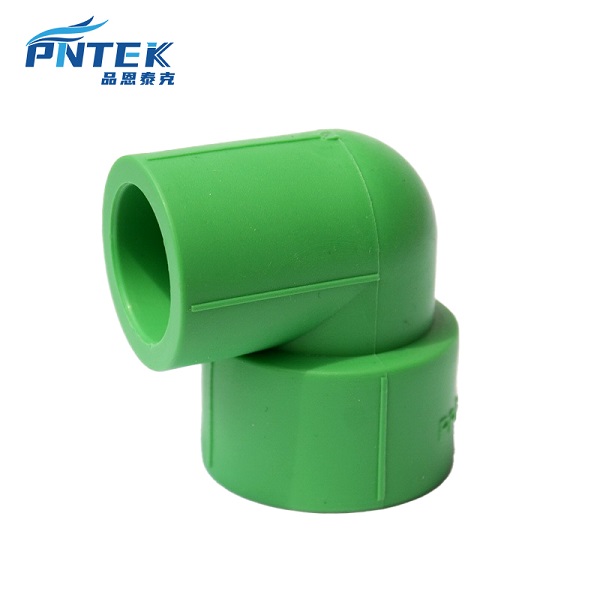

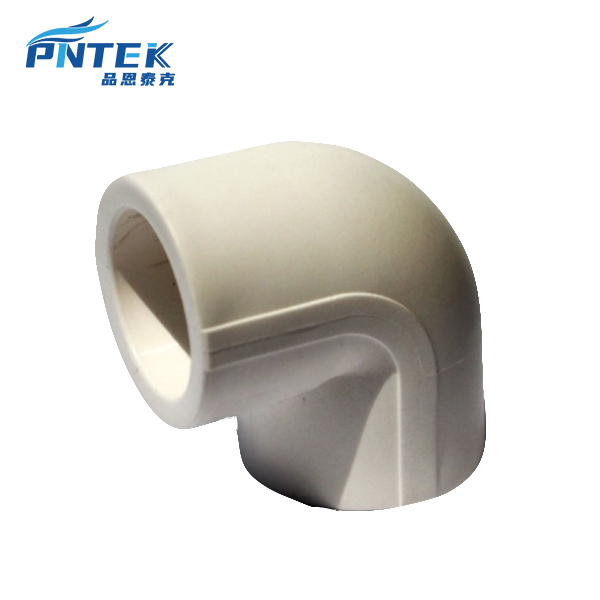

| Elbow Mould | Aluminum | 25 | 2 | 120 | Bending Pipes |

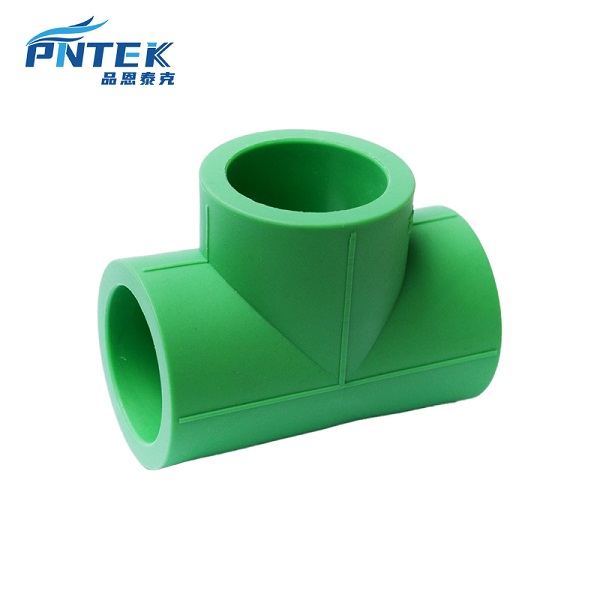

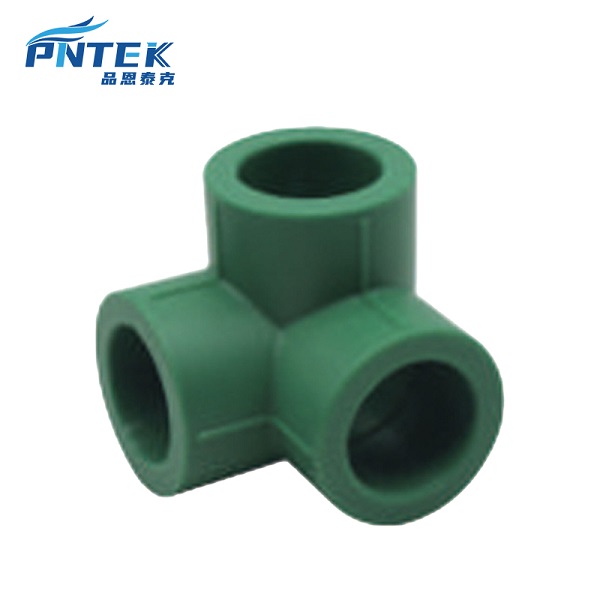

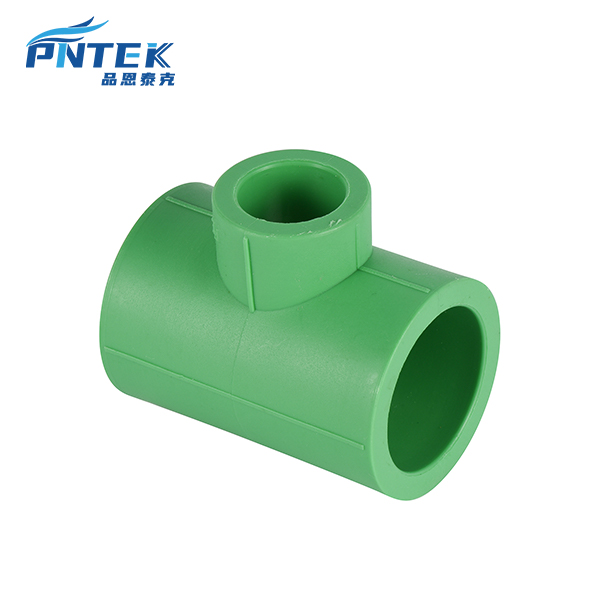

| Tee Mould | Stainless Steel | 28 | 3 | 200 | Pressure Systems |

| Cap Mould | Plastic | 20 | 1 | 80 | Water Supply |

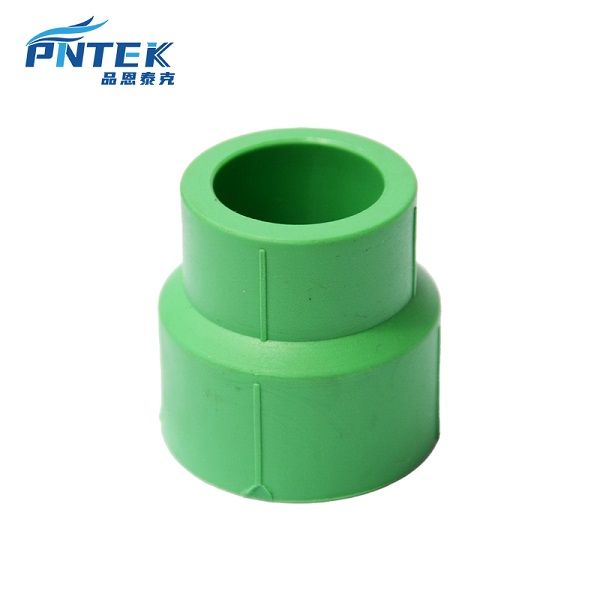

| Reducer Mould | Copper | 35 | 5 | 220 | Gas Supply |

Related Products