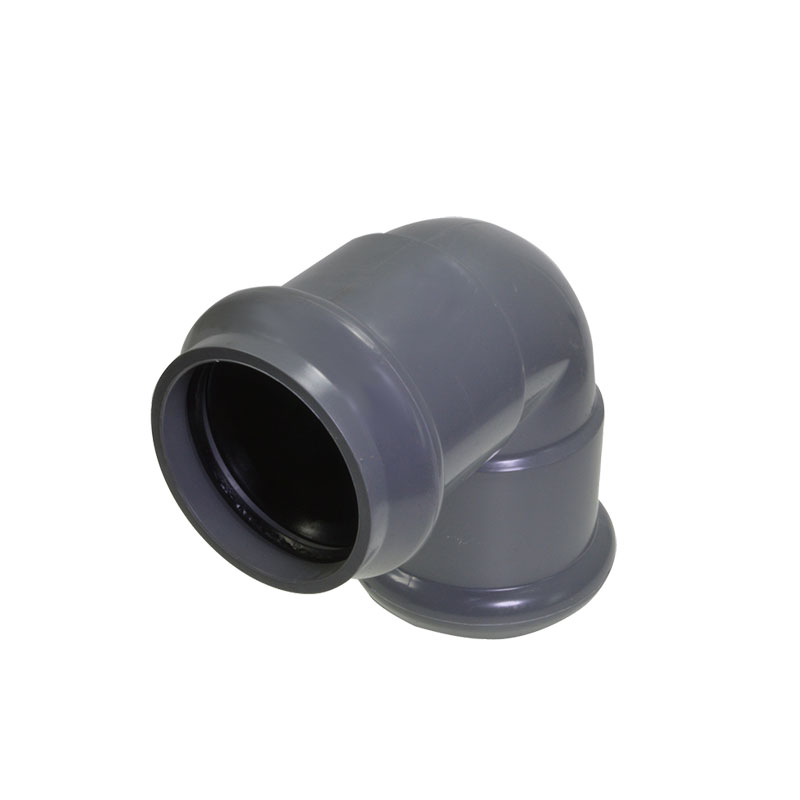

Top China Manufacturer of Spigot End Rubber Joint for Optimal Performance

As a manufacturer in China, we proudly present our Spigot End Rubber Joint, designed to meet the highest standards of quality and durability. These joints are essential for the flexibility and resilience needed in piping systems, ensuring effective pressure management and preventing leaks. I’ve seen firsthand how these rubber joints enhance the performance of various applications, from water supply to industrial uses. Our products are crafted with premium materials, guaranteeing long-lasting functionality. When you choose our Spigot End Rubber Joint, you're not just getting a product; you’re investing in reliability and efficiency for your projects. I believe in the importance of strong partnerships, and our commitment to customer satisfaction means you’ll receive not only top-quality products but also support throughout your purchasing journey. Let’s work together to meet your piping needs and elevate your operations!

Spigot End Rubber Joint Industry Leaders Market Leader

The spigot end rubber joint industry is critical for ensuring efficient and reliable connections in various piping systems. As global infrastructure projects continue to expand, the demand for high-quality rubber joints is on the rise. These components play a vital role in accommodating thermal expansion and vibrations, thereby enhancing the longevity and stability of installation systems. Consequently, industries ranging from water management to oil and gas are increasingly focused on sourcing robust solutions that meet international quality standards. In an ever-evolving market, procurement professionals must stay ahead by collaborating with industry leaders who prioritize innovation and sustainability. The latest advancements in material technology and manufacturing processes are driving the development of more resilient and versatile rubber joints. Suppliers that understand the nuances of their client’s needs and offer customizable options will hold a competitive edge. As environmental regulations tighten, sustainable manufacturing practices are becoming a key selling point for discerning global buyers. As you explore potential suppliers for spigot end rubber joints, consider the importance of quality assurance and cutting-edge designs. Engaging with experienced manufacturers ensures that you are not only receiving products that meet stringent performance criteria but also partner with a company committed to continuous improvement. With the right collaboration, you can guarantee the reliability and efficiency of your piping systems, ultimately contributing to the success of your projects on a global scale.

Spigot End Rubber Joint Industry Leaders Market Leader

| Dimension | Material Type | Pressure Rating (psi) | Temperature Range (°F) | Applications |

|---|---|---|---|---|

| 2" x 2" | EPDM | 150 | -20 to 200 | Water, Wastewater |

| 3" x 3" | NR | 200 | -10 to 180 | Oil, Fuel |

| 4" x 4" | NBR | 250 | -40 to 120 | Chemical Processing |

| 6" x 6" | Silicone | 150 | -70 to 450 | High Temperature Applications |

| 8" x 8" | Hypalon | 300 | 0 to 150 | Marine Applications |

Related Products