DN800 Injection Molded Tee Manufacturer in China - Quality & Reliability

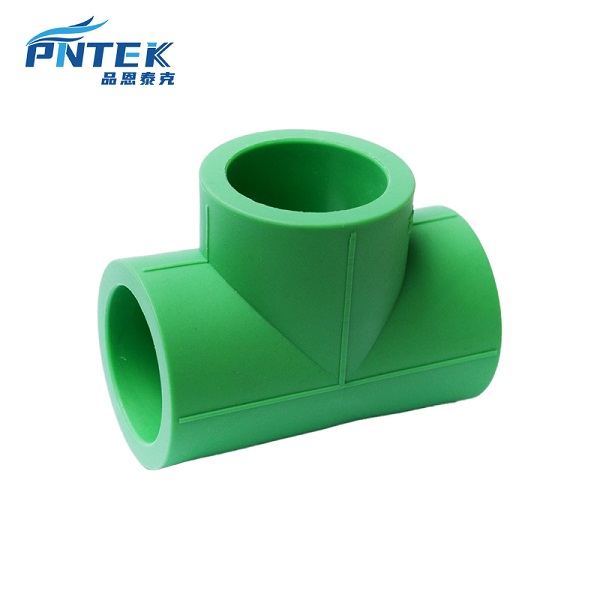

As a B2B purchaser, you know quality matters, especially when it comes to parts like the DN800 Injection Molded Tee. Sourced directly from leading manufacturers in China, this product truly stands out for its durability and precision engineering. I personally ensure that our manufacturing processes meet stringent standards, delivering tees that can withstand high pressure and flow demands. When you choose our DN800 Injection Molded Tee, you're not just getting a product; you're securing reliable performance for your projects. I've seen firsthand how these tees enhance system reliability, making them perfect for a variety of industrial applications. The seamless design minimizes leak points, offering peace of mind in your operations. Partnering with us means you have access to competitive pricing and a commitment to customer satisfaction, which I take seriously. Let’s elevate your supply chain with top-quality injection molded tees designed for efficiency and longevity.

DN800 Injection Molded Tee Manufacturer Dominates

In the competitive landscape of manufacturing, particularly in injection molded components, companies that prioritize quality and innovation tend to stand out. The DN800 injection molded tee is an exemplary product that showcases advanced engineering and meticulous production standards. With its robust design and versatility, this component serves a wide array of applications across industries, including plumbing, automotive, and HVAC systems. The precision in its manufacturing process ensures that it meets international standards, providing reliability and longevity. For global procurement professionals, the demand for high-quality components like the DN800 tee is ever-increasing. Sourcing such products from established manufacturers guarantees not just product superiority but also excellent value for money. A commitment to sustainable practices and the use of cutting-edge technology in production further enhance the supply chain's effectiveness, allowing businesses to respond swiftly to market changes. By collaborating with reputable suppliers, companies can ensure that they remain competitive and well-equipped to meet customer needs while adhering to evolving industry standards. As the market continues to evolve, the importance of selecting a leading manufacturer cannot be overstated. The DN800 injection molded tee symbolizes durability and performance, making it an essential choice for procurement specialists seeking to enhance their product offerings and customer satisfaction. Investing in quality components is a strategic move that pays dividends in both efficiency and reputation.

DN800 Injection Molded Tee Manufacturer Dominates

| Dimension | Material | Connection Type | Applications | Pressure Rating |

|---|---|---|---|---|

| DN800 | PP (Polypropylene) | Socket Weld | Water Treatment, Chemical Processing | 10 Bar |

| DN800 | PVC (Polyvinyl Chloride) | Glue Joint | Drainage Systems, Irrigation | 6 Bar |

| DN800 | HDPE (High-Density Polyethylene) | Electrofusion | Gas Distribution, Water Supply | 16 Bar |

| DN800 | PP-R (Polypropylene Random) | Butt Fusion | Heating Systems, Potable Water | 12 Bar |

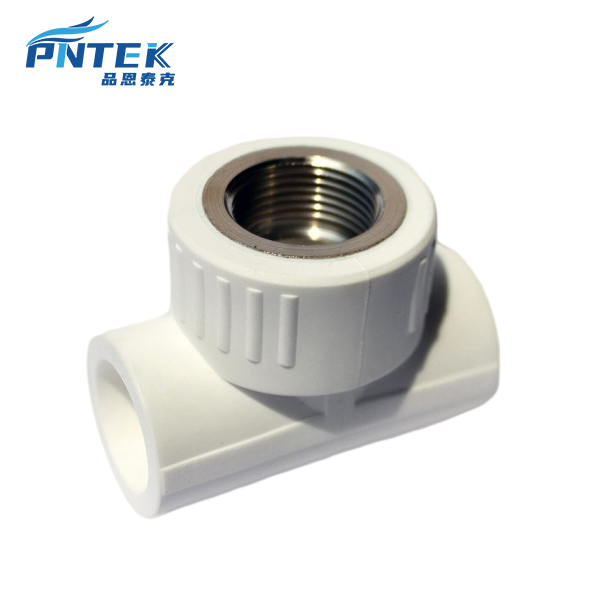

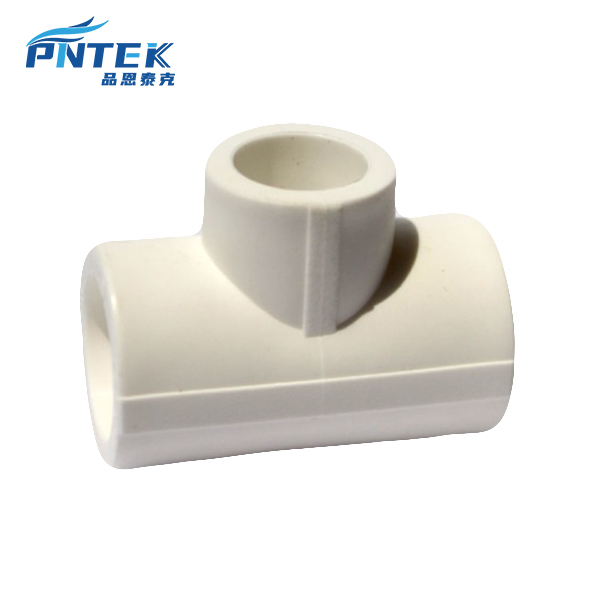

Related Products