Hdpe Electrofusion Branch Saddle - Top Manufacturer in China

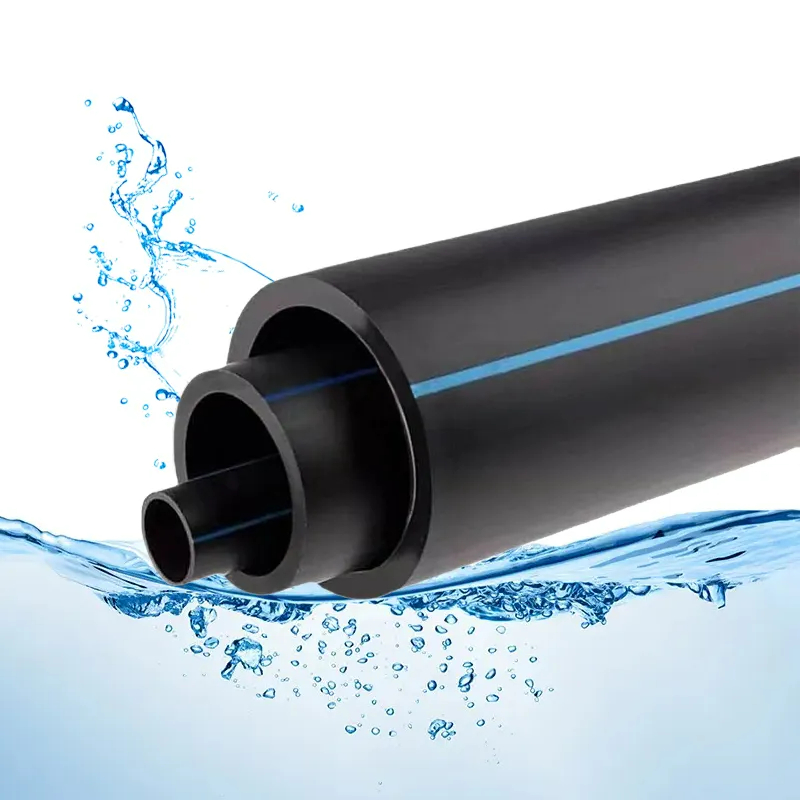

When it comes to reliable piping solutions, the Hdpe Electrofusion Branch Saddle is what I trust. This product is essential for seamless connections in various industrial applications, making it an ideal choice for manufacturers like those in China. Designed for durability, it helps ensure optimal performance and long-lasting results in any project. I have seen firsthand how easy it is to install, reducing labor costs and downtime. Plus, the electrofusion process ensures a secure and leak-proof joint, providing me peace of mind with every use. The quality of materials used in the saddle ensures that it can withstand challenging conditions, making it suitable for various environments. As a purchaser, you want proven reliability, and that’s exactly what this product delivers. Whether I’m working on new installations or repairs, the Hdpe Electrofusion Branch Saddle consistently meets my expectations. Choose this saddle for your next project, and you won’t regret it.

Hdpe Electrofusion Branch Saddle Ahead of the Curve Where Service Meets Innovation

In the dynamic world of pipeline technology, innovation and service are paramount. The recent advancements in HDPE electrofusion branch saddles offer exciting prospects for global procurement professionals seeking reliable and efficient piping solutions. These products are engineered to provide seamless connections and enhance the durability of joints, guaranteeing long-term performance even under the most demanding conditions. What sets the latest electrofusion branch saddles apart is their design, which promotes ease of installation while minimizing the risk of leaks. The innovative heating element technology ensures uniform fusion, leading to stronger and more resilient connections. Furthermore, these saddles are compatible with various pipe sizes and configurations, making them versatile for a range of applications across industries such as water supply, gas distribution, and waste management. As the industry continues to evolve, prioritizing sustainable practices and embracing cutting-edge technology is essential. With a commitment to excellence, the introduction of advanced HDPE electrofusion fittings is a step forward in supporting global procurement strategies, aligning service with innovation, and meeting the growing demands for efficient and environmentally friendly solutions. Embrace this opportunity to stay ahead of the curve and integrate quality pipe solutions into your operations.

Hdpe Electrofusion Branch Saddle Ahead of the Curve Where Service Meets Innovation

| Feature | Description | Material | Application | Standards |

|---|---|---|---|---|

| Ease of Installation | Designed for quick and efficient installation, minimizing labor costs. | High-Density Polyethylene (HDPE) | Used in water distribution and wastewater management. | ISO 4427, AS/NZS 4130 |

| Durability | Resistant to corrosion, impacts, and UV radiation. | HDPE | Suitable for high-demand applications. | ASTM D2683 |

| Compatibility | Compatible with various pipe materials including steel and PVC. | HDPE | Ideal for mixed-material installations. | EN 12201 |

| Temperature Range | Effective in a wide temperature range, making it versatile for various environments. | HDPE | Applicable in constricted and extreme climates. | ISO 14323 |

| Ease of Maintenance | Low maintenance requirements lead to lower lifecycle costs. | HDPE | Suitable for long-term installations with minimal disruptions. | ISO 2577 |

Related Products