Hdpe Pipe Fittings Elbow Pricing from China Manufacturer: Best Deals

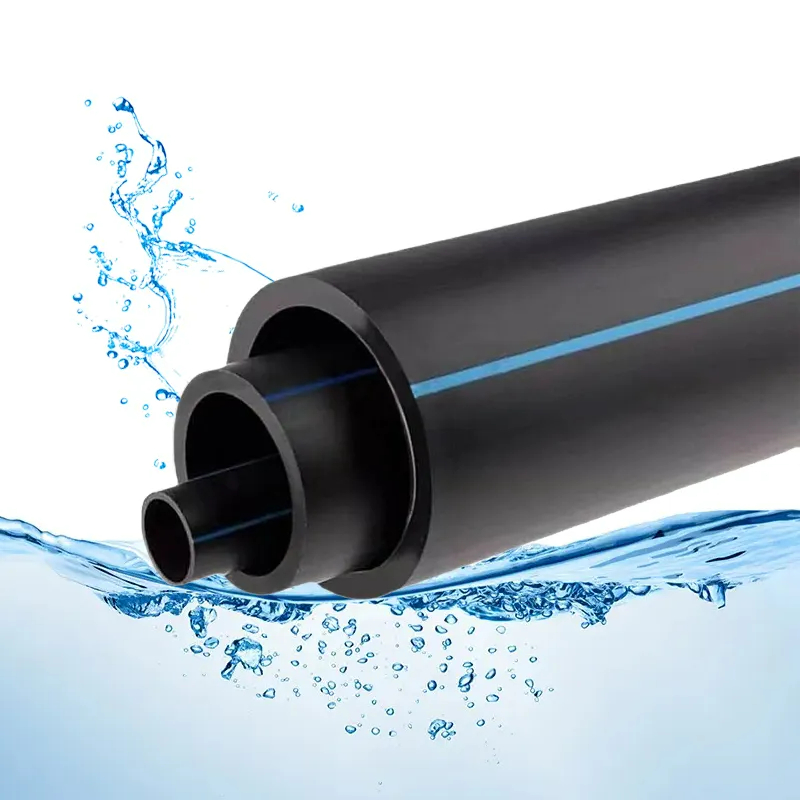

When it comes to sourcing HDPE pipe fittings elbow, I understand how crucial it is to find the right manufacturer in China who offers competitive pricing. Our HDPE elbow fittings are designed to ensure high performance and durability, making them ideal for various industrial applications. With our reliable manufacturing process, you can count on consistent quality and timely delivery, allowing you to meet your project deadlines effortlessly. Pricing is transparent and tailored to suit bulk orders, ensuring you get the best value without compromising quality. I’m here to help you navigate the options and provide you with various sizes and specifications to meet your unique needs. Let me assist you in making informed decisions for your pipeline solutions that align with industry standards. Grab the opportunity for competitive pricing and superior quality from a trusted source in China today.

Hdpe Pipe Fittings Elbow Pricing Now Trending Where Innovation Meets 2025

In today's rapidly evolving market, the pricing dynamics of HDPE pipe fittings, particularly elbows, have become a focal point for global buyers seeking innovative solutions. As we approach 2025, trends suggest that the demand for durable and versatile piping systems is on the rise, driven by construction growth, infrastructure development, and a heightened emphasis on sustainable practices. The use of high-density polyethylene (HDPE) materials not only offers excellent resistance to corrosion and chemicals but also ensures longevity in various applications, making it a preferred choice across multiple industries. As procurement professionals explore their options, it is essential to stay informed about the latest trends in HDPE elbow pricing. The market is influenced by factors such as raw material availability, production costs, and advancements in manufacturing technologies. Innovations in the production process can lead to reduced costs and improved product quality, benefiting buyers looking for cost-effective yet reliable solutions. Furthermore, as sustainability becomes a paramount concern, the integration of recycled materials in HDPE products is gaining momentum, promising additional savings and a lower environmental footprint. For global buyers, understanding regional market trends and supplier capabilities is crucial in navigating the pricing landscape. As competition intensifies, strategic partnerships with manufacturers that prioritize innovation can lead to more favorable pricing structures. By embracing new technologies and sustainable practices, suppliers are not only enhancing their product offerings but also positioning themselves as key players in the global supply chain for HDPE pipe fittings. As 2025 approaches, staying ahead of these trends will be vital for those looking to secure the best value in their procurement strategies.

Hdpe Pipe Fittings Elbow Pricing Now Trending Where Innovation Meets 2025

| Fitting Type | Material | Size (inch) | Shape | Application | Lead Time (Days) |

|---|---|---|---|---|---|

| Elbow 45° | HDPE | 2 | Angled | Water Supply | 15 |

| Elbow 90° | HDPE | 4 | Angled | Gas Distribution | 20 |

| Elbow 180° | HDPE | 6 | Curved | Drainage | 10 |

| Reducing Elbow | HDPE | 3 to 2 | Angled | Aquaculture | 25 |

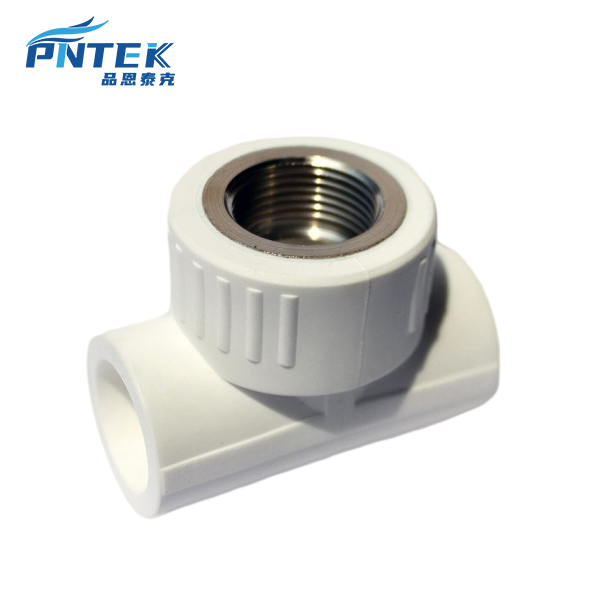

Related Products