China Manufacturer of HDPE Pipe Fittings Machines - Quality Solutions

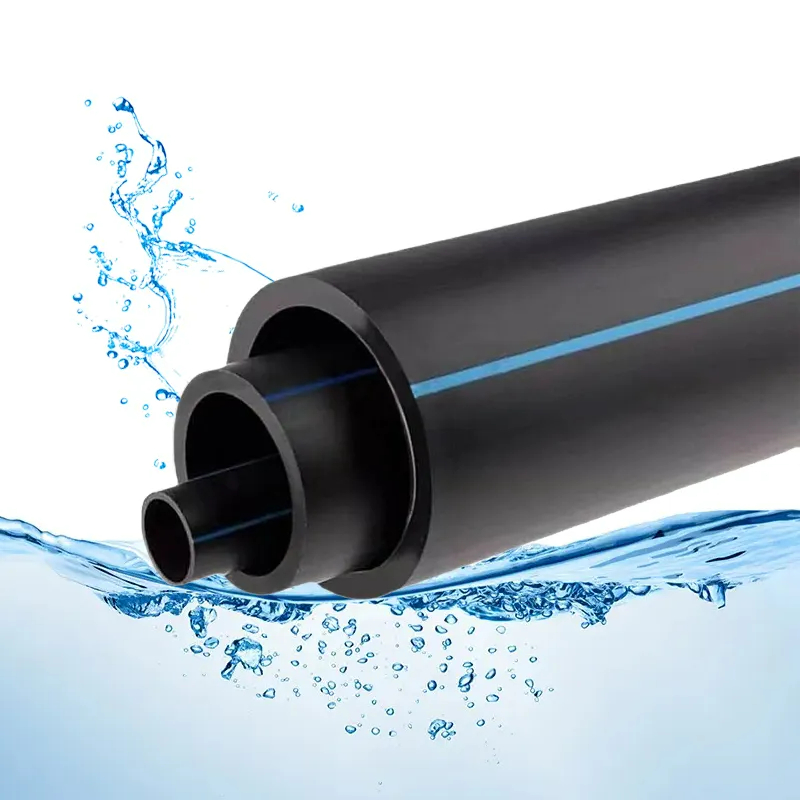

Are you in need of reliable Hdpe Pipe Fittings Machine? As a leading manufacturer in China, I understand the importance of quality and efficiency in your production line. Our machines are designed to meet high industry standards, ensuring that you get maximum output with minimal downtime. With advanced technology and user-friendly controls, these machines make it easy for you to produce durable, high-performance HDPE fittings tailored to your specific needs. Whether you're expanding your operations or starting a new project, investing in our Hdpe Pipe Fittings Machine will help you stay competitive in the market. We prioritize customer satisfaction and are committed to providing exceptional support throughout your purchasing experience. Let’s work together to enhance your manufacturing capabilities and grow your business. Don't hesitate to reach out for more information or to discuss your specific requirements!

Hdpe Pipe Fittings Machine in 2025 Custom Solutions,

As we look forward to 2025, the demand for high-density polyethylene (HDPE) pipe fittings is set to increase significantly, driven by urbanization and a global focus on sustainable infrastructure. Manufacturers are continuously seeking innovative solutions to meet these emerging needs. HDPE pipe fittings machines play a crucial role in this evolution, enabling producers to create custom solutions tailored to specific applications. The adaptability of these machines allows for precision manufacturing, which can efficiently handle various specifications while maintaining high-quality standards. Investing in advanced technology for HDPE pipe fittings production not only enhances operational efficiency but also reduces waste and energy consumption, aligning with global sustainability goals. The integration of automation and smart technologies in production lines promises to optimize performance and elevate product reliability, making it essential for businesses to adopt these innovations. As a result, procurement professionals are encouraged to explore partnerships with manufacturers who are committed to delivering cutting-edge solutions that meet diverse market demands. To stay competitive in an evolving landscape, companies should prioritize sourcing machinery that offers flexibility and scalability. Custom solutions will be key in addressing specific industry challenges, ensuring that producers can respond swiftly to market changes. As we approach 2025, embracing these trends will be paramount for businesses in the HDPE sector to thrive in a global market increasingly driven by efficiency and sustainability.

Hdpe Pipe Fittings Machine in 2025 Custom Solutions

| Dimension | Material | Usage | Custom Options | Production Rate (units/hr) |

|---|---|---|---|---|

| 25mm | HDPE | Water Supply | Color, Size | 120 |

| 32mm | HDPE | Gas Distribution | Shape, Length | 100 |

| 50mm | HDPE | Irrigation | End Type, Thickness | 80 |

| 75mm | HDPE | Drainage | Diameter, Coupling Type | 60 |

| 90mm | HDPE | Sewage | Connection Type, Material Finish | 40 |

Related Products