Top China Manufacturer of Injection Molded PE Elbows for Your Needs

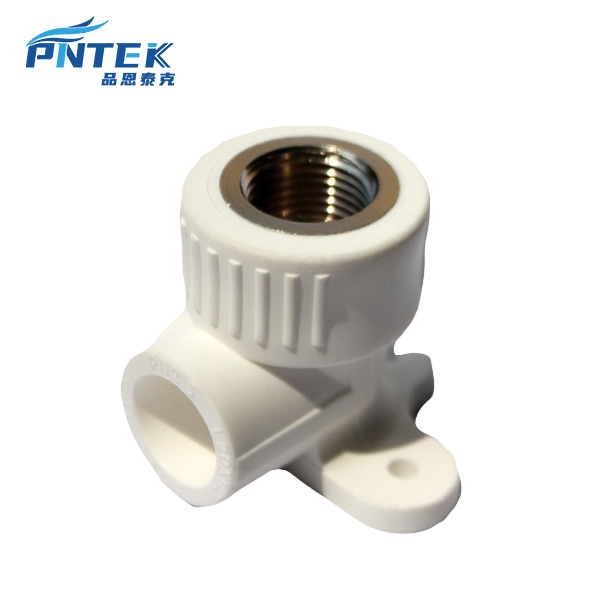

When it comes to reliable fittings, I trust our Injection Molded PE Elbow designed for seamless connections in various applications. Manufactured in China, this elbow showcases exceptional durability and resistance to various chemicals, making it an ideal choice for demanding environments. The precision molding process ensures a consistent and secure fit, helping you minimize leaks and enhance the overall efficiency of your project. I understand that quality and cost-effectiveness are crucial for B2B purchases. That’s why our Injection Molded PE Elbow stands out—offering competitive pricing without compromising on quality. By choosing our product, you’re not just getting a fitting; you’re investing in the long-term performance of your systems. With our dedicated customer support and extensive manufacturing experience, we’re here to ensure you find exactly what you need. Let's enhance your supply chain together with dependable solutions!

Injection Molded PE Elbow Factory Custom Solutions,

Injection molded polyethylene (PE) elbows are essential components in various industries, offering reliable solutions for fluid and air transfer systems. By leveraging advanced manufacturing techniques, these custom solutions can be tailored to meet specific demands, ensuring compatibility with diverse applications. The durability and resistance to corrosion and chemicals make PE elbows a preferred choice in sectors ranging from plumbing and irrigation to automotive and HVAC systems. In the global market, the need for high-quality, precise components is paramount. Injection molding allows for the efficient production of complex geometries, ensuring that every elbow fits seamlessly within existing systems. Manufacturers can provide customized sizes and designs, enabling clients to optimize their systems for performance and efficiency. This level of customization not only enhances functionality but also contributes to cost savings by reducing waste and minimizing installation time. Collaborating with a reliable partner for injection molded PE elbows can significantly impact your supply chain. When sourcing, it is crucial to consider factors such as material quality, production capabilities, and adherence to international standards. A dedicated manufacturer can offer expertise and flexibility, allowing you to focus on your core business while ensuring you receive top-notch components tailored to your operational needs. Investing in quality injection molded solutions will ultimately enhance your project's success and longevity.

Injection Molded PE Elbow Factory Custom Solutions

| Elbow Size | Angle | Material | Color | Application |

|---|---|---|---|---|

| 1/2 inch | 90° | Polyethylene | Black | Water Supply |

| 3/4 inch | 45° | Polyethylene | Green | Irrigation |

| 1 inch | 90° | Polyethylene | Blue | Gas Supply |

| 1 1/4 inch | 45° | Polyethylene | Yellow | Chemical Handling |

| 2 inch | 90° | Polyethylene | Transparent | Drainage |

Related Products