Top China Manufacturer of Injection Molded PE Fittings for Your Needs

When you need reliable and high-quality injection molded PE fittings, I know that sourcing from a trustworthy manufacturer in China can make all the difference. Our fittings are designed to meet rigorous industry standards, ensuring durability and efficiency in diverse applications. With years of experience in the market, we guarantee that our products are crafted using top-grade materials, optimizing performance and longevity. I understand that when you’re making purchasing decisions, you want value for your investment. Our injection molded PE fittings not only offer cost-efficiency but also ease of installation and maintenance. We pride ourselves on providing exceptional customer service and quick turnaround times, allowing you to meet your project deadlines without hassle. Trust us as your partner in sourcing top-quality fittings that can enhance your operations. Let’s discuss how our products can fit into your business needs and help you achieve greater efficiency.

Injection Molded PE Fitting Stands Out Where Service Meets Innovation

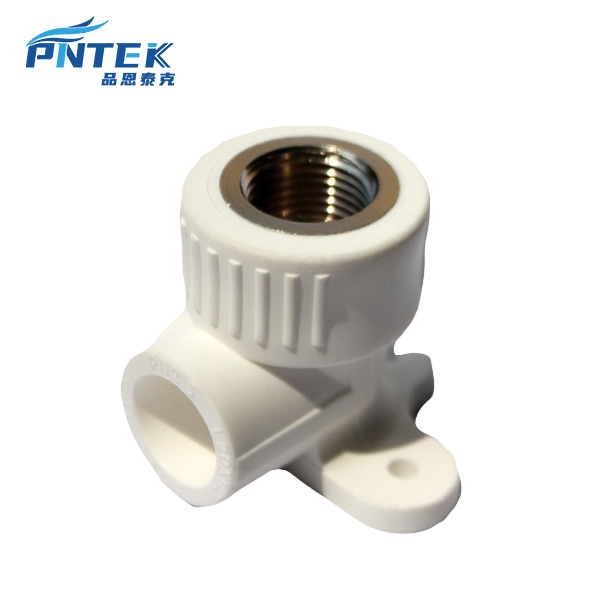

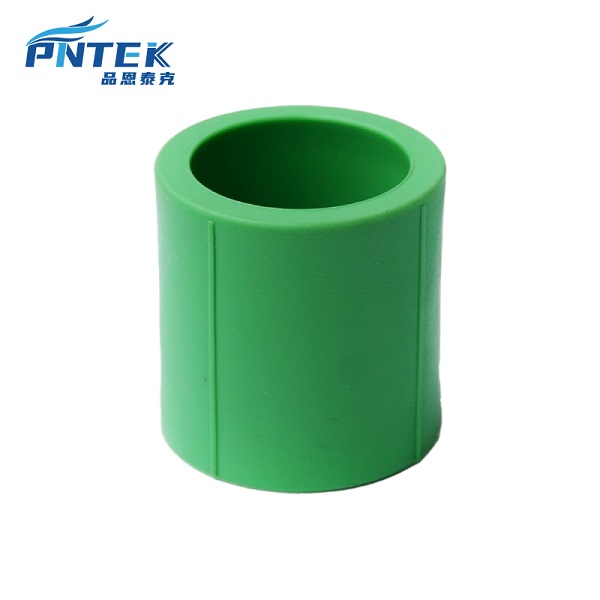

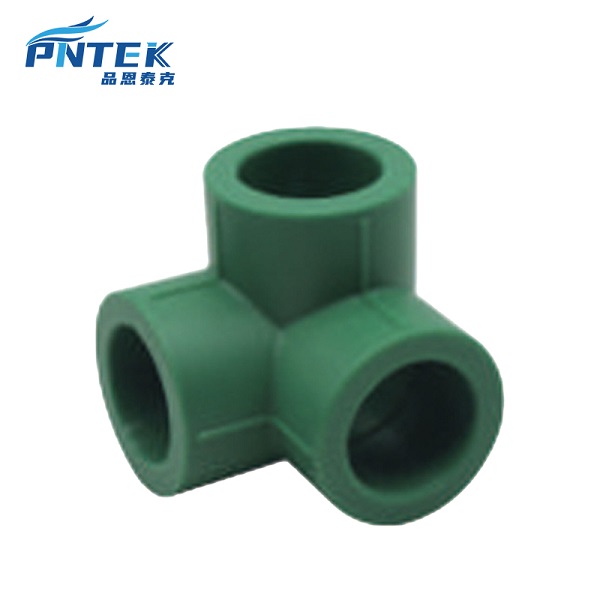

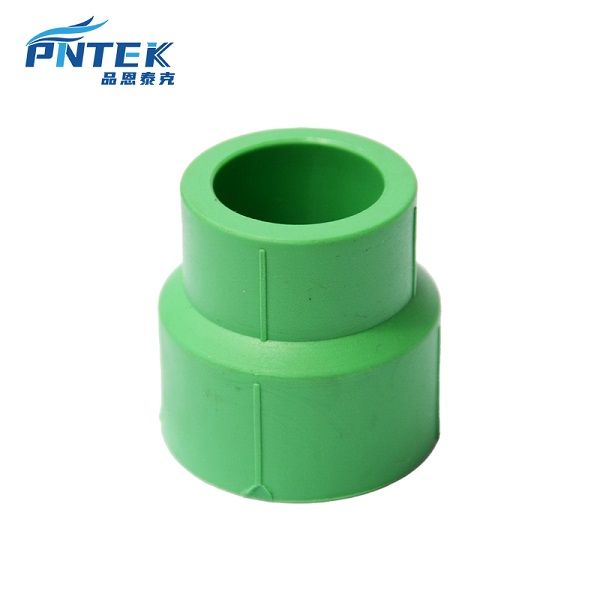

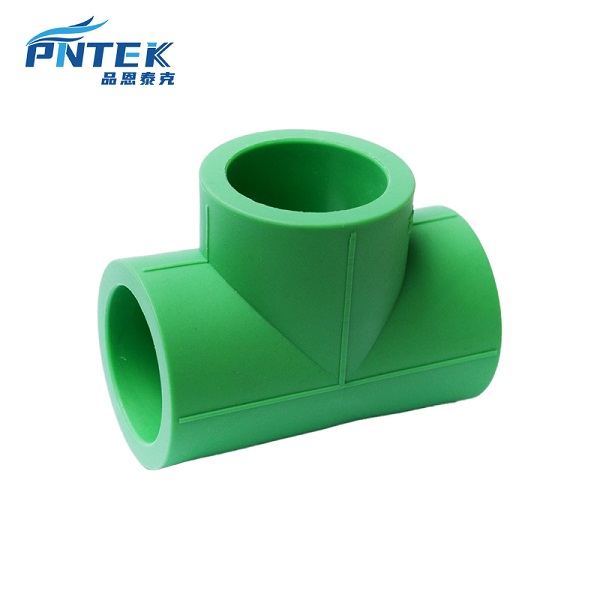

In the competitive landscape of industrial fittings, the injection molded PE fitting has emerged as a game-changer, seamlessly merging practicality with innovative design. This cutting-edge solution is tailored for global buyers looking for reliability and performance in their applications. Injection molding technology not only ensures precision but also enhances the durability and efficiency of the fittings, making them ideal for various industries, including plumbing, irrigation, and drainage. What sets these fittings apart is their exceptional resistance to harsh environments and chemicals, ensuring longevity and reducing the need for frequent replacements. Additionally, the streamlined production process allows for customization to meet specific client requirements, facilitating a quicker response to market demands. As businesses increasingly prioritize sustainability, injection molded PE fittings are designed to be eco-friendly, further attracting environmentally conscious purchasers. In a world where service excellence is just as crucial as product quality, our commitment to providing tailored solutions and robust customer support complements the innovative nature of these fittings. For global buyers seeking advanced, reliable, and sustainable options, our injection molded PE fittings represent the perfect blend of innovation and service, setting new standards in the industry.

Injection Molded PE Fitting Stands Out Where Service Meets Innovation

| Dimension | Material | Application | Innovative Feature | Service Type |

|---|---|---|---|---|

| 1/2 inch | Polyethylene (PE) | Plumbing | Crack Resistant | Fast Delivery |

| 3/4 inch | Polyethylene (PE) | Irrigation | UV Stabilized | Custom Solutions |

| 1 inch | Polyethylene (PE) | Industrial | High Pressure Rated | 24/7 Support |

| 2 inch | Polyethylene (PE) | Municipal Water | Anti-Corrosion | Technical Assistance |

| 4 inch | Polyethylene (PE) | Drainage | Flexible Joint Design | On-site Training |

Related Products