Top Non Return Ball Valve Manufacturer in China for Quality Solutions

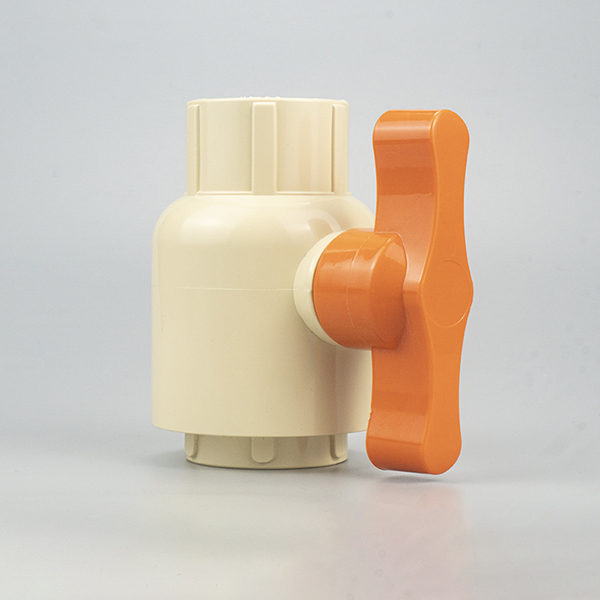

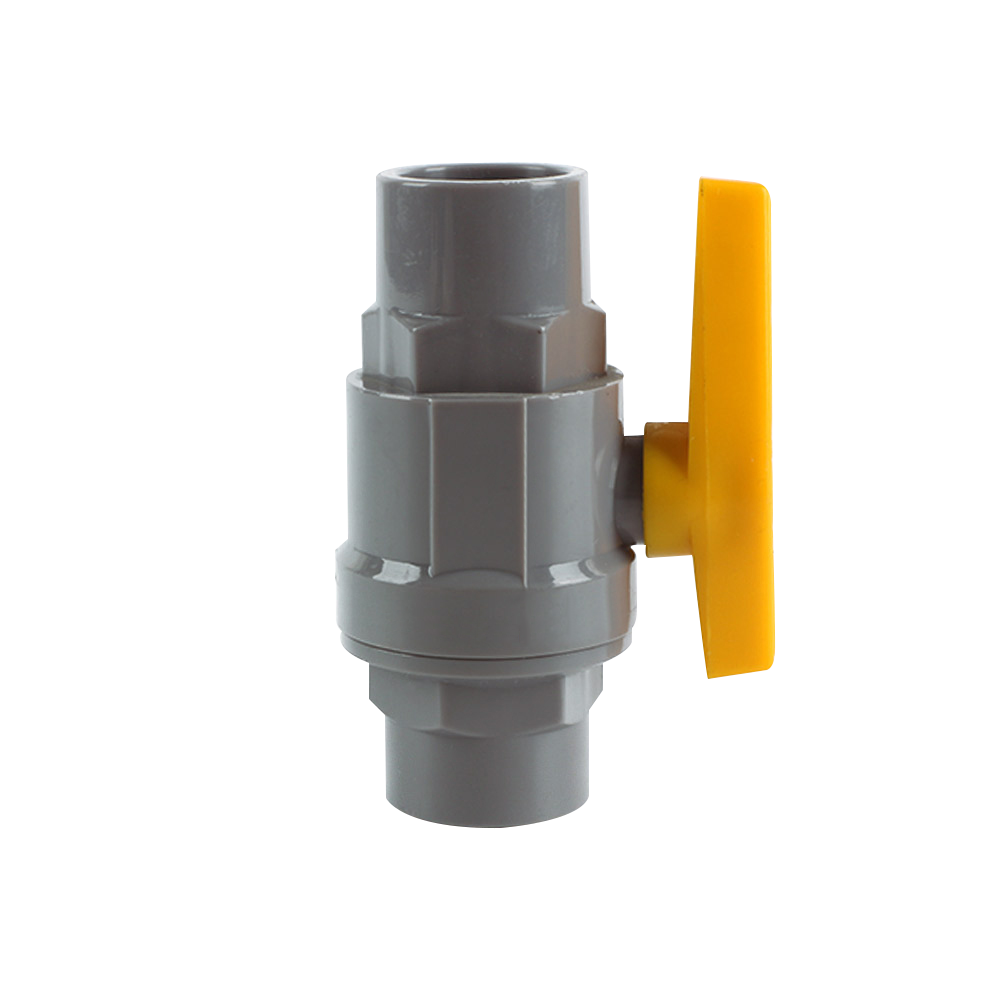

In my experience as a trusted supplier of Non Return Ball Valves, I’ve found that quality and durability are key factors for B2B purchasers. Our Non Return Ball Valves, manufactured to the highest standards in China, ensure reliable performance in various industrial applications. These valves effectively prevent backflow, protecting your systems and enhancing operational efficiency. I take pride in our robust manufacturing process, which adheres to strict quality controls, ensuring each valve is built to last. With a focus on reliability, we’ve designed these valves for easy installation and low maintenance, making them the perfect choice for your projects. Whether you’re looking to enhance your supply chain or improve your production capabilities, we are ready to meet your needs with competitive pricing and flexible ordering options. Let’s connect to discuss how our Non Return Ball Valves can benefit your business and contribute to your success.

Non Return Ball Valve Application Market Leader

In the ever-evolving landscape of industrial applications, non-return ball valves have emerged as essential components for ensuring efficient and secure fluid control. These valves play a crucial role in preventing backflow, thereby enhancing the safety and reliability of various systems in sectors such as oil and gas, water treatment, and chemical processing. Their unique design, which allows fluid to flow in one direction while blocking reverse flow, makes them ideal for high-pressure environments where integrity is paramount. As global demand for durable and high-performance valve solutions continues to rise, the non-return ball valve market is witnessing significant growth. Manufacturers and suppliers are increasingly focusing on innovation, with advancements in materials and design that cater to the specific needs of various industries. Buyers seeking to enhance their operational efficiency can benefit from exploring the latest technologies that provide improved sealing capabilities and longer service life, ultimately reducing maintenance costs and downtime. For procurement professionals looking to optimize their supply chain, partnering with leading manufacturers of non-return ball valves can offer a competitive advantage. By investing in proven technologies and reliable sources, companies can ensure that their infrastructure remains robust and capable of meeting the demands of modern applications. Emphasizing quality and performance in sourcing decisions not only enhances operational safety but also supports sustainable practices by minimizing resource waste through improved system efficiency.

Non Return Ball Valve Application Market Leader

| Application | Market Share (%) | Growth Rate (CAGR %) | Region | Key Features |

|---|---|---|---|---|

| Water Supply Systems | 30 | 5.5 | North America | High durability, Low maintenance |

| Oil and Gas | 25 | 4.8 | Middle East | Chemical resistance, High pressure tolerance |

| Power Generation | 20 | 6.2 | Asia Pacific | Reliable sealing, Wide temperature range |

| Chemical Processing | 15 | 3.9 | Europe | Corrosion resistance, Precise flow control |

| HVAC Systems | 10 | 4.0 | Latin America | Energy efficient, Space saving design |

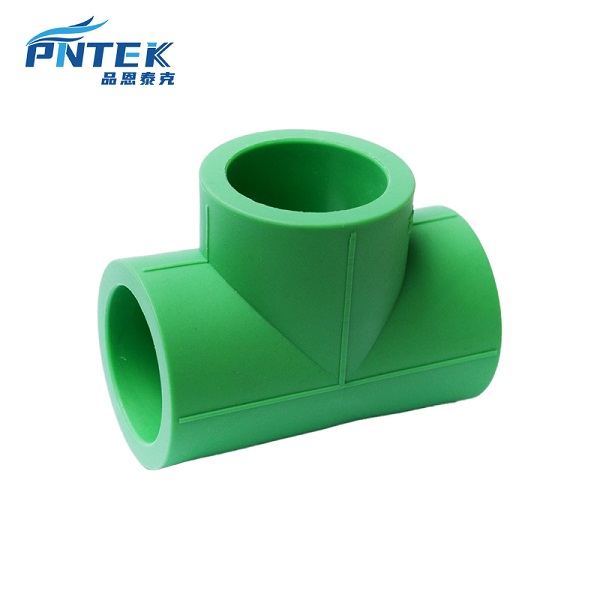

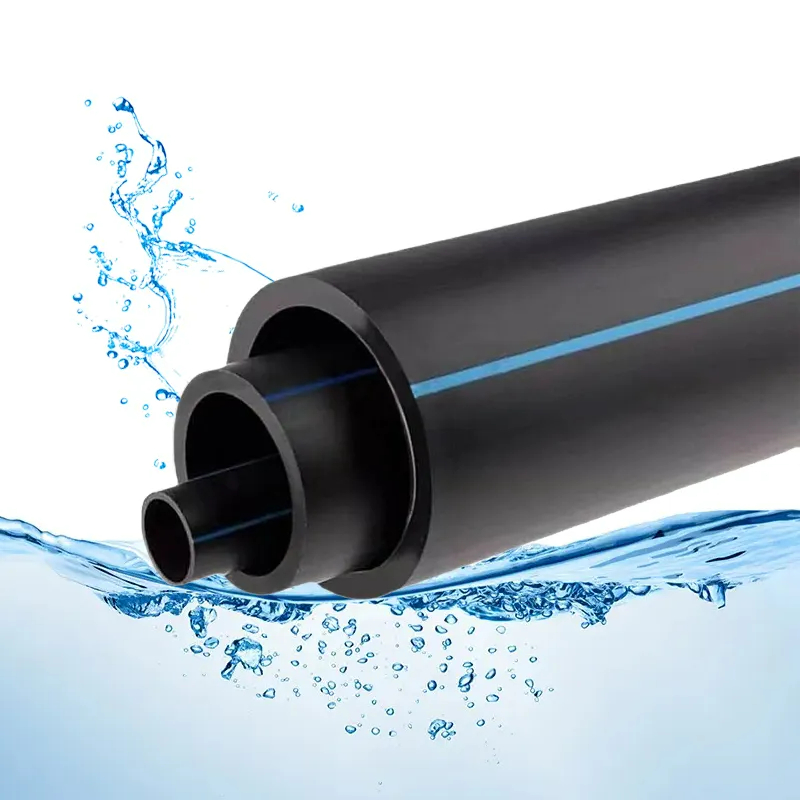

Related Products