Top PP Valves Manufacturer in China: Quality Solutions for Your Needs

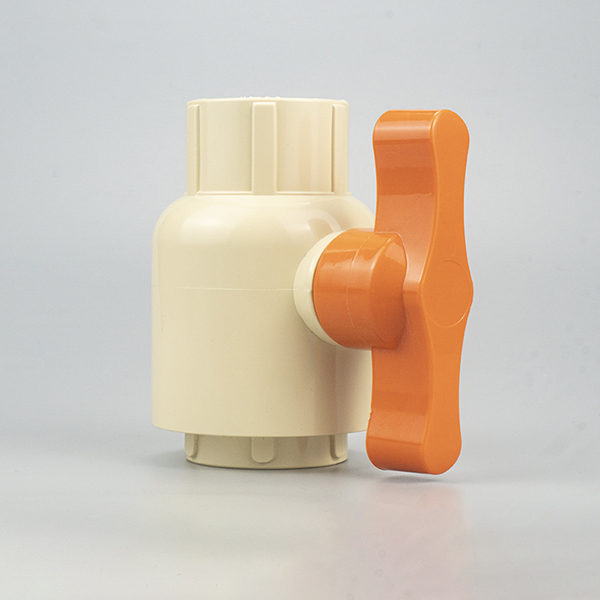

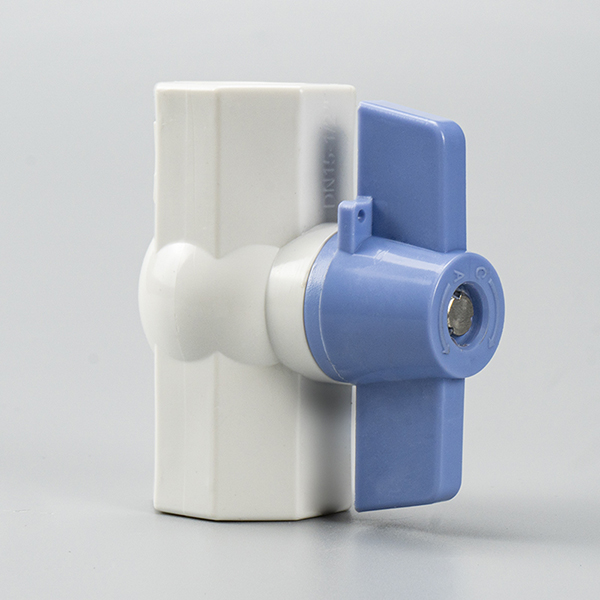

When searching for reliable PP valves, I understand the importance of quality and performance. As a trusted manufacturer in China, our products are designed with durability and efficiency in mind, suitable for a variety of applications. I've seen firsthand how these valves outperform others in tough environments, offering peace of mind for users. What sets our PP valves apart is that they are crafted using advanced techniques and high-grade materials. They’re resistant to corrosion and ensure a leak-free operation, which is exactly what you need in industrial settings. I take pride in the fact that we provide comprehensive support and tailored solutions to meet your specific requirements. You can rely on us not just for products, but also for excellent customer service and technical guidance throughout the purchasing process. With our commitment to exceptional quality and reliability, you're making a smart choice for your business needs. Let’s take the next step together!

PP Valves Now Trending Where Service Meets Innovation

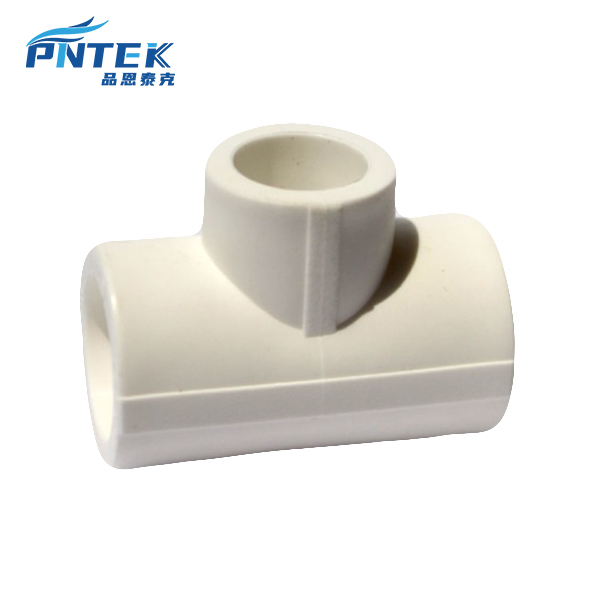

In today's rapidly evolving industrial landscape, the demand for high-quality, reliable, and innovative solutions has never been more critical. One area that has seen impressive advancements is the valve industry, particularly with the rise of PP valves. These products are not just becoming a staple in manufacturing and process applications but are also setting new benchmarks for efficiency and sustainability. The latest trends highlight how these valves are redefining service delivery through their exceptional durability and performance. PP valves are crafted from high-performance polypropylene, which offers exceptional resistance to chemicals and corrosion. This makes them an ideal choice for various industries, including chemical processing, water treatment, and food and beverage. As global procurement professionals seek efficient solutions, the integration of such innovations into operational frameworks ensures reduced downtime and maintenance costs. Furthermore, with the ability to handle high pressure and temperature, these valves meet stringent industry standards while promoting eco-friendly practices. Moreover, service excellence is paramount in the procurement decision-making process. Suppliers that leverage cutting-edge technology to enhance customer support and streamline logistics will stand out in a competitive marketplace. By focusing on these dual pillars of service and innovation, businesses can secure a competitive edge, attract discerning clients, and foster long-term partnerships in the ever-expanding global market.

PP Valves Now Trending Where Service Meets Innovation

| Dimension | Material | Application | Temperature Range | Certifications |

|---|---|---|---|---|

| 1/2 inch | Polypropylene | Water Supply | -10°C to 80°C | ISO 9001 |

| 3/4 inch | Polypropylene | Chemical Handling | -20°C to 90°C | FDA Compliant |

| 1 inch | Polypropylene | Oil & Gas | -30°C to 100°C | CE Marked |

| 1 1/4 inch | Polypropylene | Food Processing | -10°C to 75°C | NSF Certified |

| 1 1/2 inch | Polypropylene | HVAC Systems | -40°C to 90°C | RoHS Compliant |

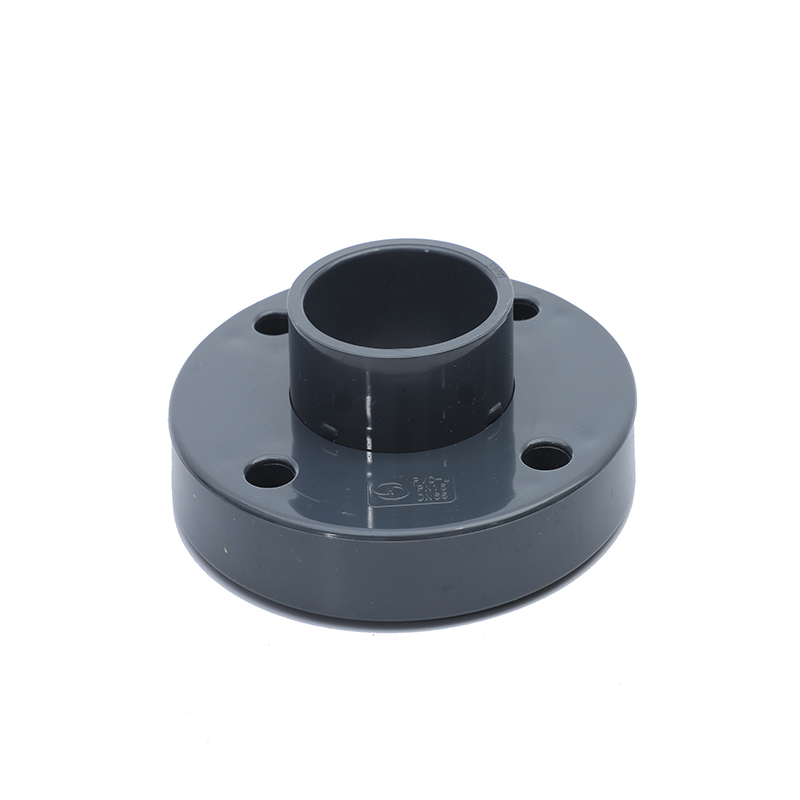

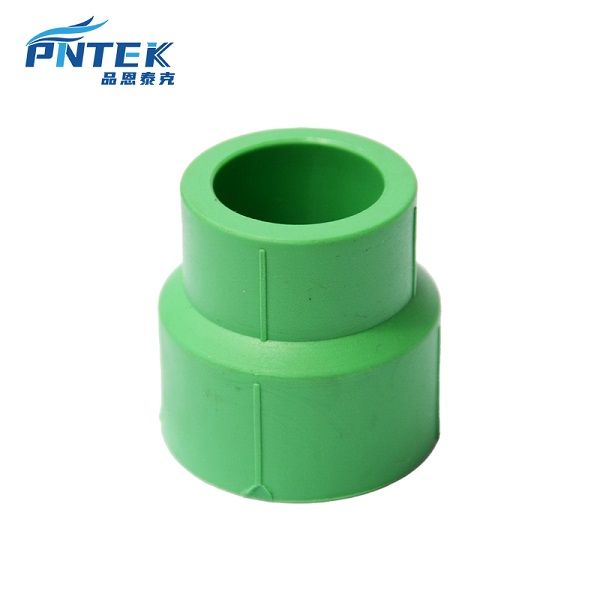

Related Products