Explore Top Valve Types from Leading China Manufacturers

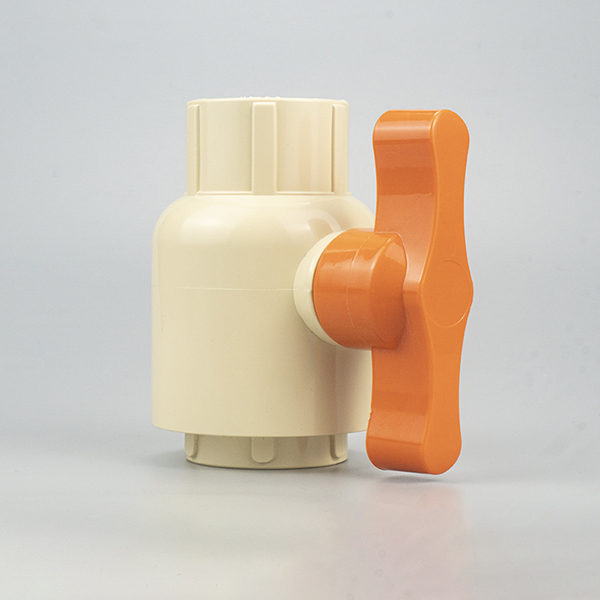

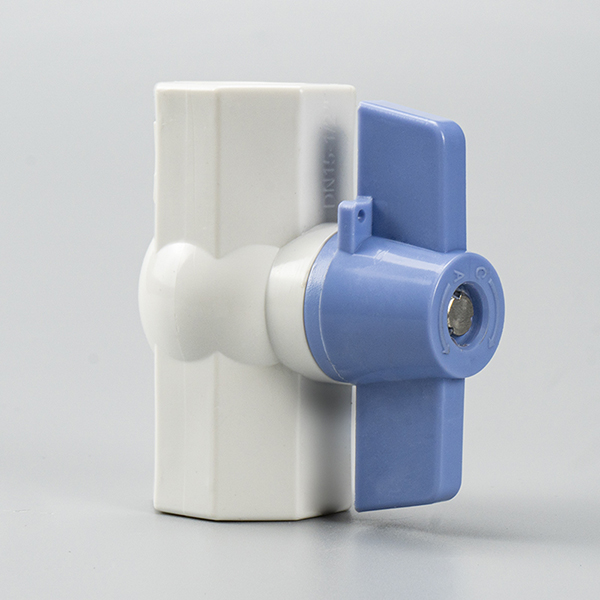

When it comes to selecting the right valves types for your projects, understanding your options can make all the difference. As a professional in sourcing quality components, I've found that valves come in various designs catering to specific needs—whether it’s for controlling flow, pressure, or direction. Sourcing from reliable manufacturers in China has proven beneficial for consistent quality and cost-effectiveness. Our extensive range includes ball valves, gate valves, check valves, and more, ensuring that every requirement is met. What sets us apart is not just our product variety but our dedication to customer satisfaction. Partnering with a trusted China manufacturer means you can expect durability and performance that meets international standards. Feel free to reach out if you’re interested in learning more about our valve types and how we can help optimize your operations with our high-quality solutions.

Valves Types Dominates Industry Giant

In the ever-evolving landscape of industrial manufacturing, the variety and functionality of valve types play a crucial role in determining process efficiency and operational integrity. From regulating fluid flow to controlling pressures, the right valve type can significantly impact performance across numerous sectors, including oil and gas, water treatment, and chemical processing. Understanding which valve types dominate the industry can aid global purchasers in making informed decisions that enhance their operations. Among the most commonly employed valve types are globe valves, ball valves, and butterfly valves, each offering unique advantages. Globe valves are renowned for their excellent throttling capabilities and reliability, making them ideal for applications that require variable flow control. Ball valves, prized for their swift operation and minimal pressure drop, are essential in applications demanding quick shut-off. Butterfly valves, with their compact design and lightweight structure, are popular in large-scale industrial processes where space and weight constraints are critical. Businesses looking to optimize their systems must evaluate how these valves can work seamlessly within their operational framework. Moreover, anticipating industry trends such as automation and sustainability enhances the procurement strategy. The increasing incorporation of smart technologies in valve manufacturing can lead to more efficient monitoring and control, contributing to energy savings and reduced environmental footprints. As global sourcing of these essential components continues to grow, staying informed about innovative valve technologies will be crucial for organizations committed to maintaining a competitive edge in their respective industries.

Valves Types Dominates Industry Giant

| Valve Type | Application | Material | Size Range | Pressure Rating |

|---|---|---|---|---|

| Ball Valve | Oil & Gas | Stainless Steel | ½" to 12" | 150 to 600 psi |

| Gate Valve | Water Supply | Cast Iron | 2" to 60" | 150 to 300 psi |

| Globe Valve | Power Generation | Brass | ½" to 24" | 150 to 900 psi |

| Check Valve | Chemical Processing | PVC | 1" to 12" | 50 to 150 psi |

| Butterfly Valve | HVAC Systems | Aluminum | 2" to 48" | 150 to 300 psi |

Related Products