Electrofusion Fittings: Leading China Manufacturer for Quality Solutions

When it comes to sourcing premium Electrofusion Fittings, I've found that choosing a reliable manufacturer from China can make a world of difference. These fittings provide a seamless joining solution for pipes, ensuring durability and a leak-free connection, which is essential for any project. As someone who’s dealt with various suppliers, I appreciate the quality and efficiency Chinese manufacturers offer in producing these specialized fittings. The range of sizes and types available means I can easily find the right fit for my needs, whether for industrial applications or residential projects. Plus, the competitive pricing helps keep my budget in check while maintaining high standards. Working with a Chinese manufacturer gives me confidence in obtaining products that not only meet international quality standards but also adhere to stringent regulations. With Electrofusion Fittings, I know I’m investing in long-lasting performance and reliability for my business.

Electrofusion Fittings Application Custom Solutions,

In the dynamic world of industrial solutions, electrofusion fittings offer a robust and reliable method for joining polyethylene pipes, vital for various applications in sectors such as water management, gas distribution, and telecommunications. These fittings utilize an electrofusion process, which involves the application of electrical energy to melt the surface of the fitting and pipe, creating a seamless and durable bond. With increasing demand for high-quality, custom-engineered solutions, businesses are seeking suppliers that can provide tailored fittings that meet specific requirements, including size, pressure ratings, and environmental considerations. Global procurement professionals are increasingly focused on sourcing materials that guarantee efficiency and longevity while reducing maintenance costs. Custom electrofusion fittings can be designed to suit various operational environments, ensuring optimal performance in extreme temperatures, corrosive environments, or high-pressure applications. Moreover, manufacturers are leveraging advanced technologies to enhance the precision and reliability of these fittings, further elevating their suitability for international standards and projects. Choosing the right partner for electrofusion fittings not only enhances project execution but also ensures adherence to regulatory compliance and sustainability goals. Companies that prioritize innovation and customer-centric solutions can provide significant advantages in today's competitive market, helping businesses streamline operations while maintaining the highest quality standards. By exploring custom electrofusion fitting solutions, global buyers can secure the best options for their project needs, contributing to successful outcomes and long-term partnerships.

Electrofusion Fittings Application Custom Solutions

| Application | Material | Size Range | Pressure Rating | Standards |

|---|---|---|---|---|

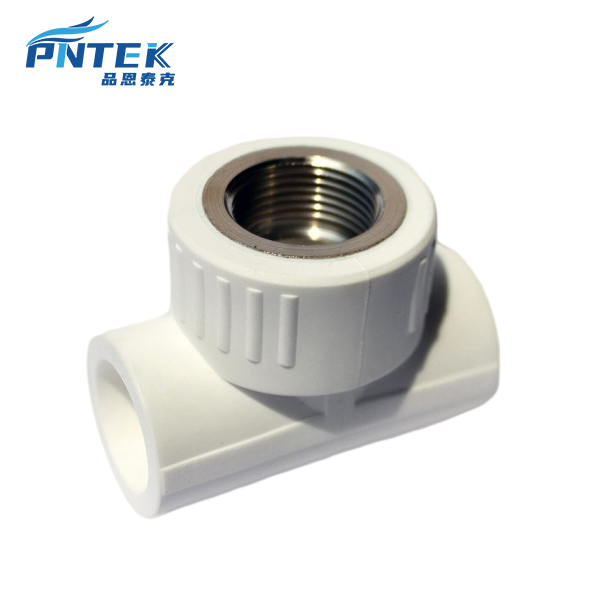

| Water Supply | PE100 | 20mm - 630mm | SDR11 | ISO 4427 |

| Gas Distribution | PE80 | 20mm - 200mm | SDR17 | ISO 4437 |

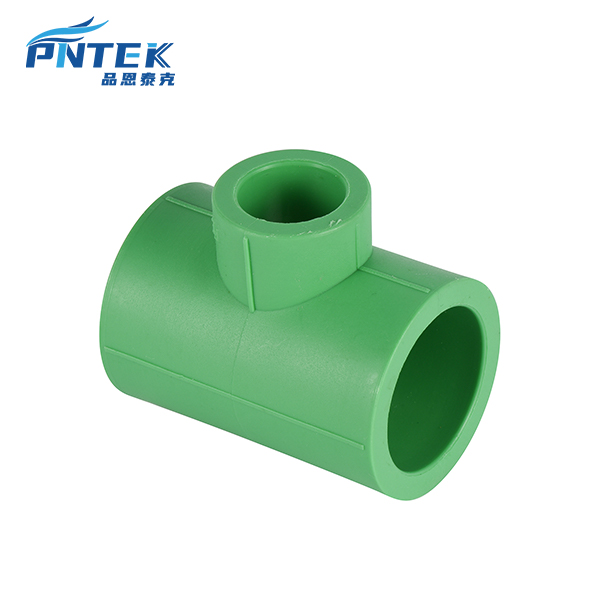

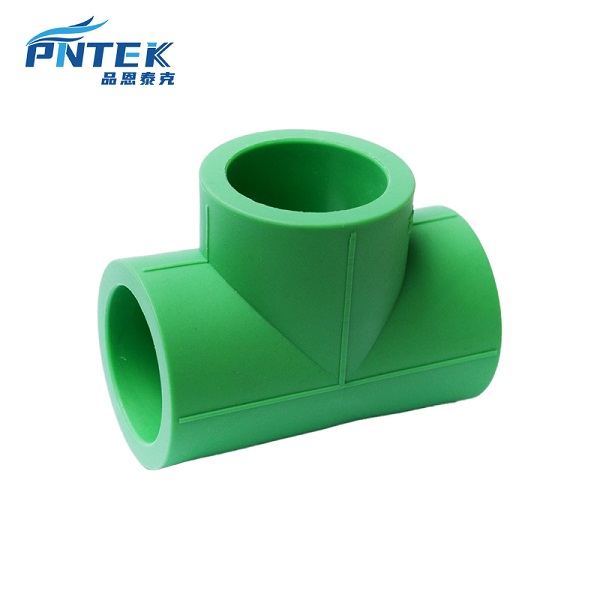

| Industrial Applications | PP | 25mm - 500mm | PN10 | ASTM D3261 |

| Wastewater | PVC | 32mm - 400mm | SDR26 | ASTM D3034 |

| Irrigation | HDPE | 16mm - 250mm | SDR17 | AS/NZS 4129 |

Related Products