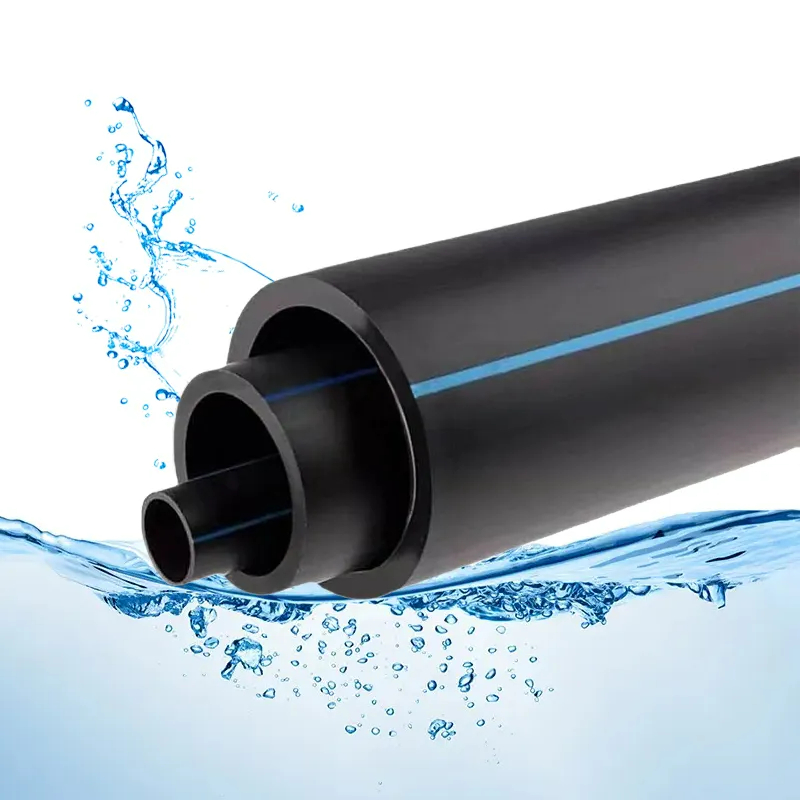

Top Electrofusion HDPE Manufacturer in China for Quality Solutions

When it comes to sourcing high-quality Electrofusion HDPE fittings, I understand the importance of reliability and performance in your projects. Manufactured in China, our products meet rigorous industry standards, ensuring excellence in every application. With years of experience, we pride ourselves on being a trusted manufacturer that provides durable and efficient solutions for water, gas, and industrial piping systems. Our Electrofusion HDPE fittings are designed for easy installation and superior strength, making them ideal for both new constructions and repairs. I know that finding the right supplier is crucial for your business, and I’m here to help simplify your decision. With competitive pricing and consistent quality control, you can rely on us for all your Electrofusion needs. Let’s work together to elevate your projects with our top-notch products that can withstand the test of time.

Electrofusion Hdpe Manufacturer For the Current Year

In the ever-evolving world of industrial materials, electofusion HDPE technology has emerged as a game changer, particularly for those in need of durable and reliable solutions. As companies worldwide look to optimize their supply chains and reduce costs, sourcing high-quality electofusion HDPE products is becoming increasingly critical. The current year presents unique opportunities for global buyers, as manufacturers are ramping up their production capabilities to meet increasing demand while adhering to stringent quality standards. The key to successful procurement lies in understanding the manufacturing processes and the innovative technologies that enhance the reliability of electofusion HDPE products. High-density polyethylene (HDPE) is known for its toughness and resistance to corrosion, making it an ideal choice for a variety of applications, including piping systems, water management, and infrastructure. By partnering with manufacturers that leverage state-of-the-art technologies and rigorous testing methods, buyers can ensure they are receiving products that not only comply with international standards but also enhance the longevity and performance of their projects. In addition to quality, sustainability is becoming a focal point for procurement strategies. Many manufacturers are now emphasizing eco-friendly practices by incorporating recycled materials and energy-efficient processes in their production lines. This shift not only meets growing environmental regulations but also aligns with the corporate social responsibility goals of buyers. As the marketplace continues to expand, staying informed about the latest advancements in electofusion HDPE manufacturing will empower global purchasers to make decisions that benefit both their projects and the planet.

Electrofusion Hdpe Manufacturer For the Current Year

| Manufacturer Location | Production Capacity (tons/year) | Certification | Year Established | Main Application |

|---|---|---|---|---|

| United States | 5000 | ISO 9001 | 2005 | Water Supply |

| Germany | 3000 | ISO 14001 | 2010 | Gas Distribution |

| China | 8000 | CE | 2015 | Drainage |

| Italy | 4000 | SGS | 2012 | Industrial |

| Brazil | 6000 | ISO 45001 | 2008 | Irrigation |

Related Products