Top China Manufacturer of HDPE Hot Melt Fittings for Quality Solutions

When I explore options for HDPE hot melt fittings, I often find myself drawn to high-quality products from reliable manufacturers in China. These fittings are essential for creating strong, durable connections in piping systems, and they have become a staple in various industries. As a purchaser, I appreciate the seamless installation and excellent resistance to chemicals and environmental stress that these fittings provide. Sourcing HDPE hot melt fittings from reputable China manufacturers guarantees not just superior performance but also competitive pricing. The advanced technology used in their production ensures long-lasting durability, making them an ideal choice for both small and large-scale projects. Whether it's for construction, plumbing, or agricultural applications, these fittings meet high standards and help streamline operations. If you're keen on boosting efficiency and reducing downtime in your projects, I'd recommend considering high-quality HDPE hot melt fittings for your next procurement.

Hdpe Hot Melt Fittings Ahead of the Curve Winning in 2025

As industries evolve, so do the materials and methods we rely on for efficient and sustainable solutions. HDPE (High-Density Polyethylene) hot melt fittings are shaping the future of plumbing and liquid transportation systems, offering exceptional durability, resistance to corrosion, and ease of installation. As we look ahead to 2025, the demand for these advanced fittings is anticipated to surge, driven by a growing emphasis on sustainability and energy efficiency across various sectors. These hot melt fittings offer a seamless connection that significantly reduces the likelihood of leaks compared to traditional joining methods. With their high resistance to temperature fluctuations, they are ideal for a range of applications, from residential plumbing to large-scale industrial projects. The global shift towards eco-friendly materials is also pushing the industry towards innovative solutions that reduce environmental impact, making HDPE fittings a top choice for forward-thinking companies. Investing in HDPE hot melt fittings is not just about current needs; it's a strategic move for future-proofing projects. As regulatory frameworks become increasingly stringent and consumers demand higher standards of quality and reliability, incorporating these fittings into supply chains will position businesses favorably in a competitive market. Embracing this technology today means aligning with the principles of sustainability and efficiency that will define successful operations in 2025 and beyond.

| Category | Material Type | Application | Temperature Range (°C) | Standard Compliance |

|---|---|---|---|---|

| HDPE Fittings | High-Density Polyethylene | Water Supply | -40 to 60 | ISO 4427 |

| Fittings Accessories | Polypropylene | Gas Distribution | -20 to 80 | EN 1555 |

| Joint Fittings | Cross-Linked Polyethylene | Waste Management | 0 to 80 | ASTM D2661 |

| Adapters | Polyethylene | Irrigation | -10 to 70 | AS/NZS 4129 |

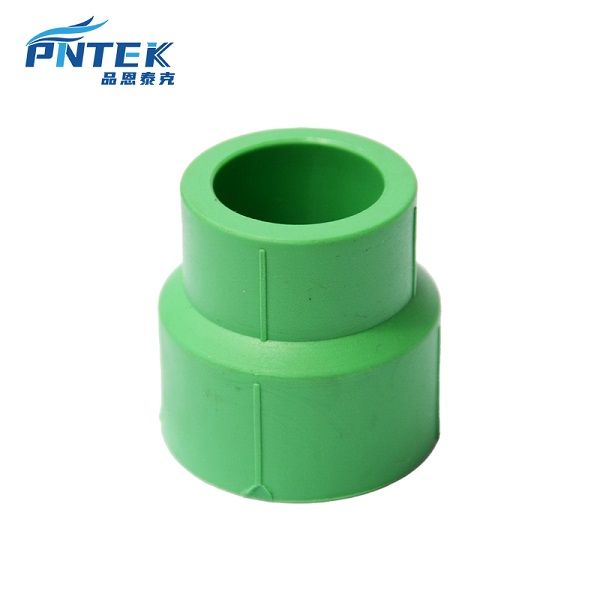

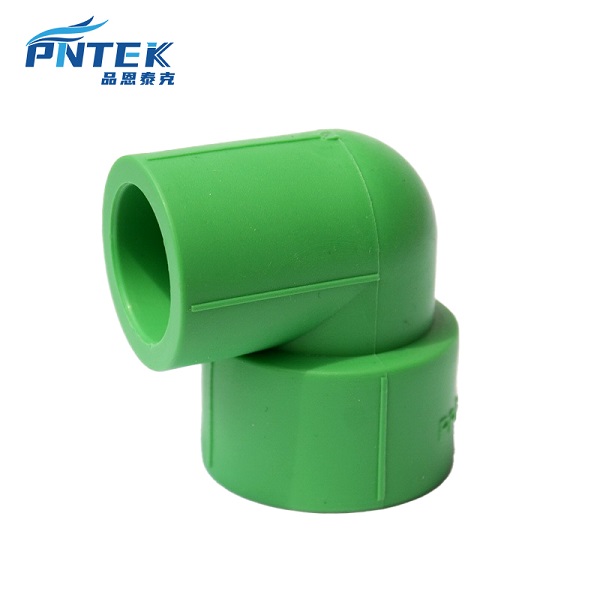

| Elbows | Polymer Blend | Industrial Applications | -40 to 90 | ISO 9001 |

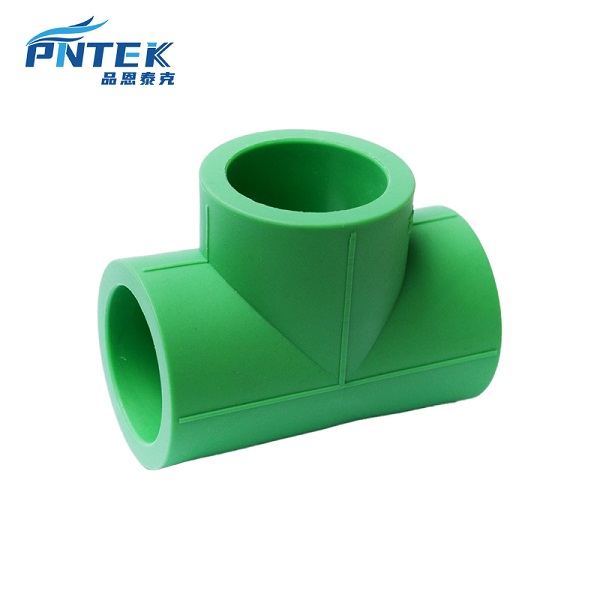

Related Products