Hdpe Pipe Joint Fittings Manufacturer in China - Quality & Reliability

As a leading manufacturer in China, I understand the importance of durable and reliable HDPE pipe joint fittings for your projects. Our products are designed to provide long-lasting performance, ensuring that your pipeline systems remain efficient and secure. With advanced manufacturing techniques and strict quality control, we ensure that every fitting exceeds industry standards. Whether you're working on agricultural irrigation, water supply systems, or industrial applications, our HDPE pipe joint fittings are perfect for any configuration. I pride myself on offering a wide range of sizes and types to meet the diverse needs of our clients. Plus, with our commitment to customer satisfaction, I’m always here to support you with expert advice and tailored solutions. When you choose our HDPE fittings, you’re not just purchasing a product; you’re investing in peace of mind, knowing that you're using top-quality materials for your infrastructure needs. Let's connect and discuss how we can help you achieve your project goals efficiently.

Hdpe Pipe Joint Fittings Industry Leaders Where Service Meets Innovation

In the dynamic landscape of the HDPE pipe joint fittings industry, where service meets innovation, leaders are continuously redefining quality and efficiency. The demand for high-performance joint fittings is on the rise, driven by industries that require reliable solutions for fluid transport, from agriculture to industrial applications. By adopting advanced manufacturing technologies and innovative design practices, leading companies are not only enhancing product durability but also ensuring consistent performance under varying conditions. Global procurement specialists are increasingly looking for suppliers who provide not just products but comprehensive services that foster strong partnerships. A commitment to customer support, including timely delivery and customized solutions, plays a crucial role in decision-making. The integration of smart technologies, such as predictive maintenance and real-time monitoring, is transforming traditional practices, offering procurement managers greater transparency and control over their supply chains. As the industry evolves, sustainability remains a key focus. Leaders in the HDPE pipe joint fittings market are exploring eco-friendly materials and production methods, aligning their practices with global environmental standards. By investing in innovative solutions that prioritize both performance and sustainability, these companies are well-equipped to meet the growing expectations of global buyers seeking to enhance their operational efficiency while minimizing their ecological footprint.

Hdpe Pipe Joint Fittings Industry Leaders Where Service Meets Innovation

| Dimension | Material Type | Application | Connection Type | Innovation Features |

|---|---|---|---|---|

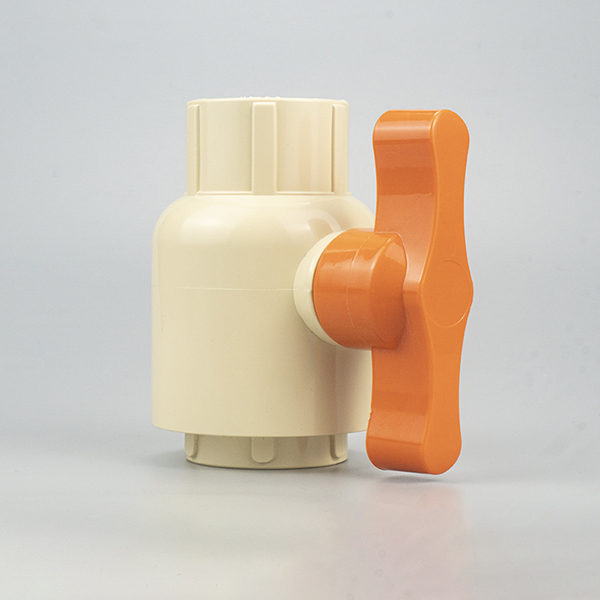

| 2 inch | HDPE | Water Supply | Butt Fusion | Enhanced Leak Resistance |

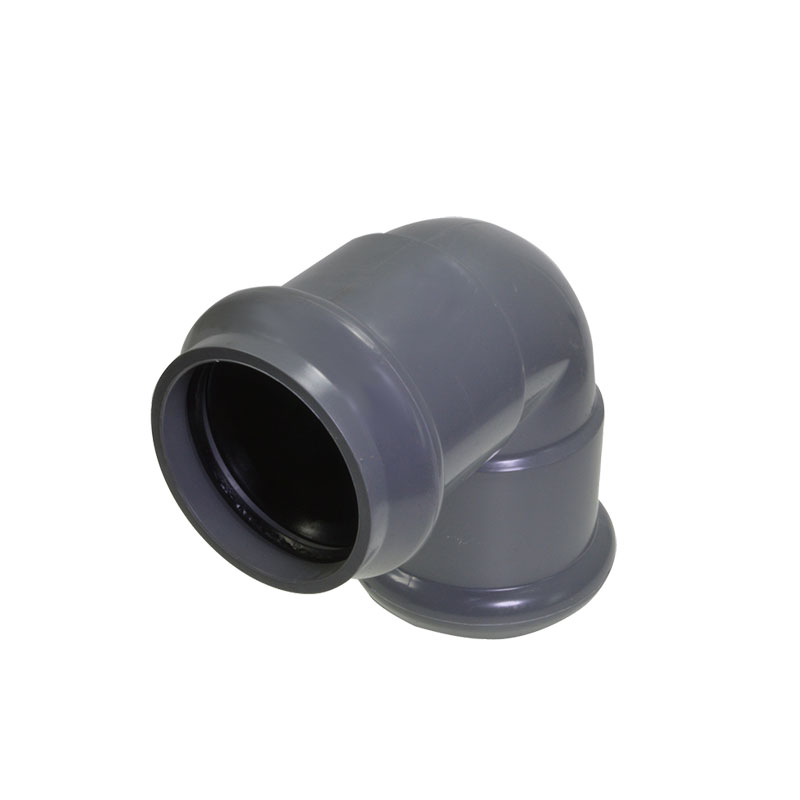

| 4 inch | PVC | Drainage | Socket Weld | Corrosion Resistance |

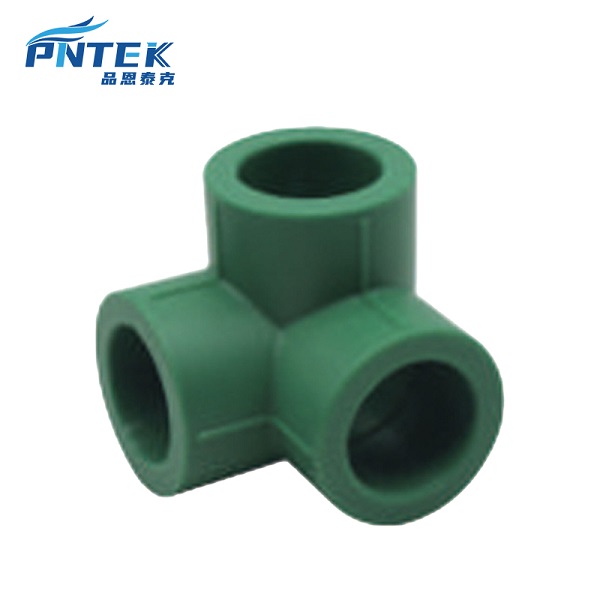

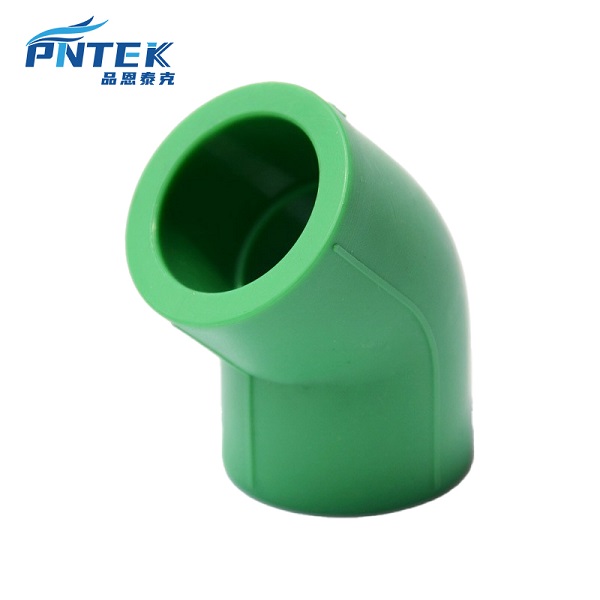

| 6 inch | PP | Chemical Processing | Electrofusion | High Impact Resistance |

| 8 inch | PVC | Irrigation | Flange | UV Stabilization |

| 10 inch | HDPE | Wastewater | Mechanical Joint | Flexible Design |

Related Products