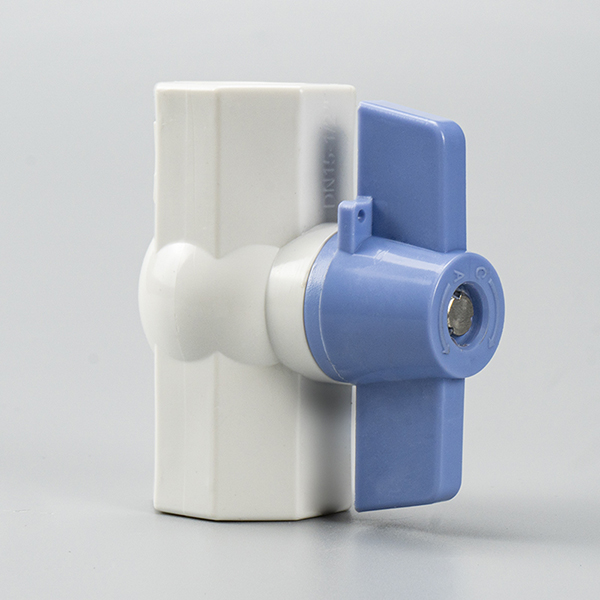

Top China Manufacturer of Plastic Shut-Off Valves for All Applications

As someone who understands the unique needs of B2B purchasers, I can confidently say that our Plastic Shut-Off Valve is a game-changer. Sourced directly from reputable manufacturers in China, these valves offer exceptional reliability and durability at competitive prices. Whether you're in manufacturing, construction, or any industry requiring precision flow control, this valve is designed to meet your needs effectively. With an impressive selection tailored for various applications, you’ll find these valves easy to install and maintain. Plus, the lightweight plastic construction ensures corrosion resistance and minimizes transportation costs. I’ve seen firsthand how these valves enhance operational efficiency, allowing businesses to keep processes running smoothly. Let’s talk about a solution that not only fits your budget but also provides outstanding performance. Reach out to us to discuss how our Plastic Shut-Off Valves can add value to your operations. Let’s connect and elevate your business together!

Plastic Shut-Off Valve Leads the Global Market Delivers Unmatched Quality

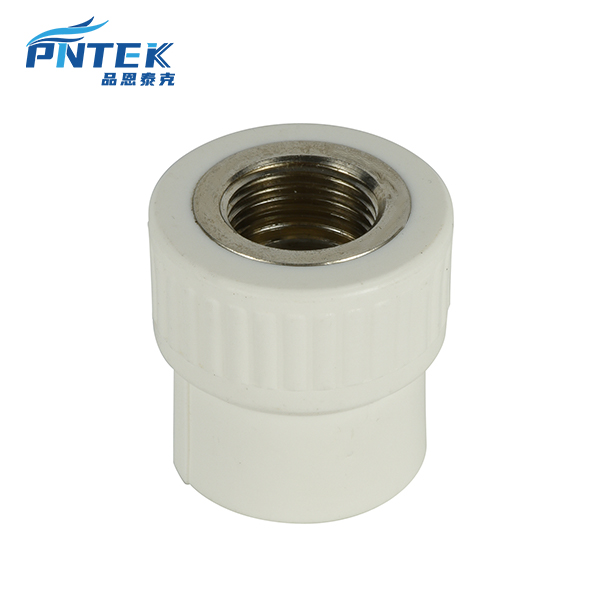

In the evolving landscape of industrial components, plastic shut-off valves have emerged as a critical component across various applications. Renowned for their reliability and efficiency, these valves play a crucial role in fluid control systems, making them an indispensable choice for industries ranging from water treatment to chemical processing. The global demand for these valves has surged, driven by their unmatched quality, lightweight design, and resistance to corrosion, all of which contribute to prolonged operational efficiency and reduced maintenance costs. The unique attributes of plastic shut-off valves make them an ideal solution for modern industrial challenges. Their superior performance in harsh environments, coupled with ease of installation, positions them as the preferred choice among procurement professionals seeking cost-effective and durable options. Additionally, advancements in manufacturing technology have enabled the production of these valves to meet the highest international standards, ensuring consistent quality and reliability. This commitment to excellence not only enhances operational safety but also minimizes downtime, which is crucial for maintaining productivity in competitive markets. As global suppliers strive to meet the increasing demand, the focus on sustainability is more pronounced than ever. The adoption of eco-friendly materials and processes in the production of plastic shut-off valves showcases a commitment to environmental responsibility. For procurement professionals, partnering with manufacturers who prioritize quality and sustainability represents a strategic advantage in today's conscientious market. Investing in high-quality plastic shut-off valves can lead to significant long-term returns, making them a smart choice for businesses looking to optimize their supply chains while enhancing overall operational performance.

Plastic Shut-Off Valve Leads the Global Market Delivers Unmatched Quality

| Dimension | Measurement | Material | Pressure Rating | Temperature Range | Applications |

|---|---|---|---|---|---|

| 1/2 inch | 15 mm | PVC | 150 PSI | -20 to 60 °C | Water Supply, Irrigation |

| 3/4 inch | 20 mm | CPVC | 200 PSI | -10 to 80 °C | Chemical Processing, water treatment |

| 1 inch | 25 mm | PP | 150 PSI | -20 to 70 °C | Oil & Gas, HVAC systems |

| 1 1/4 inch | 32 mm | PVC | 150 PSI | -20 to 60 °C | Piping, Agricultural Irrigation |

| 1 1/2 inch | 40 mm | CPVC | 200 PSI | -10 to 80 °C | Industrial Flow Control |

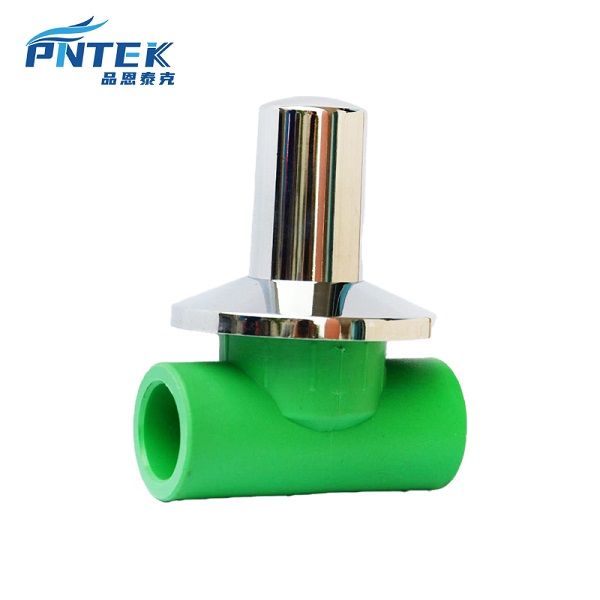

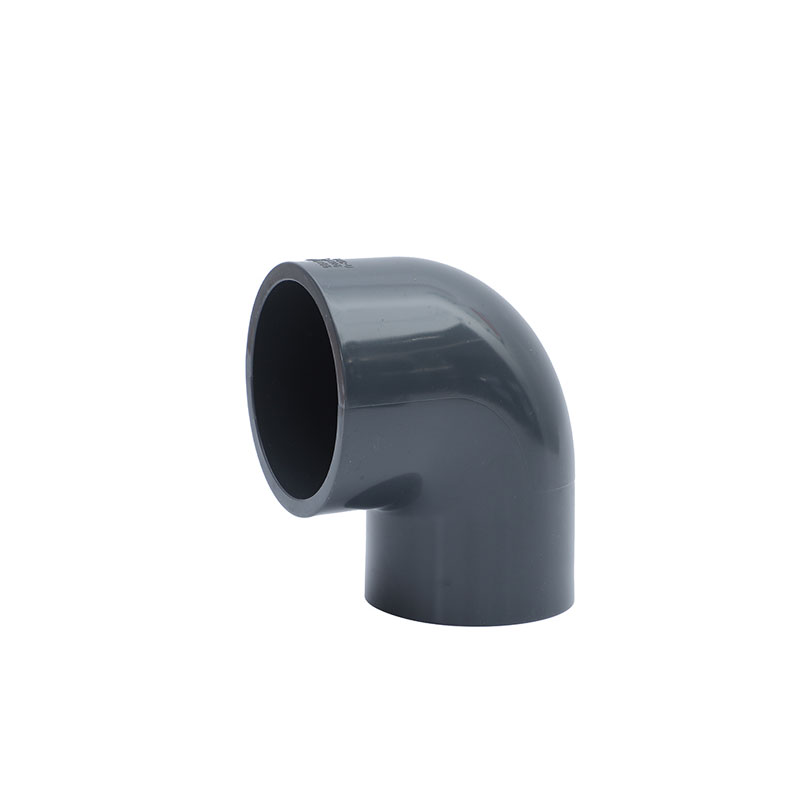

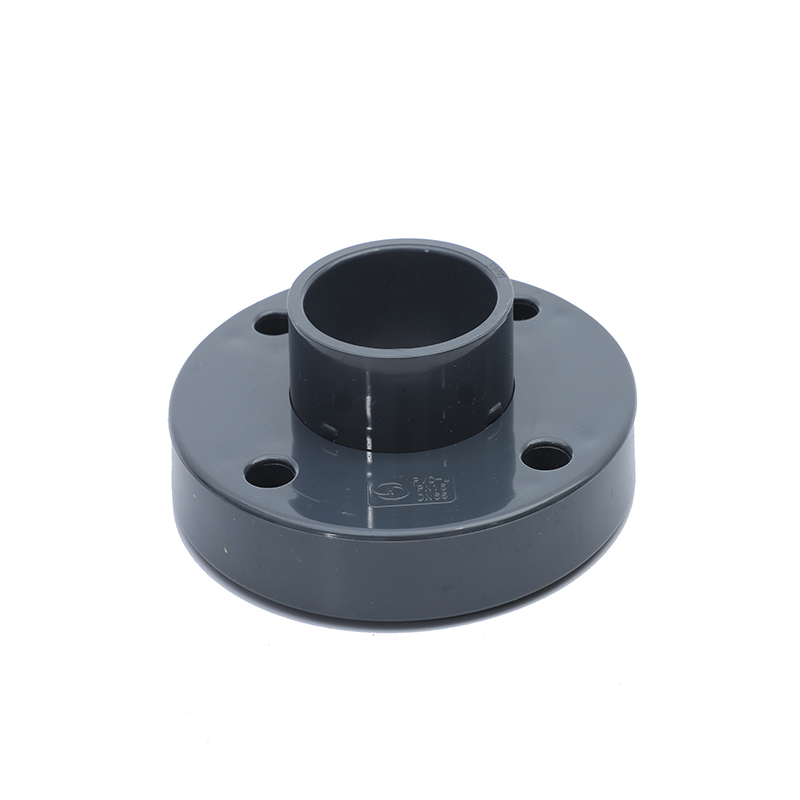

Related Products