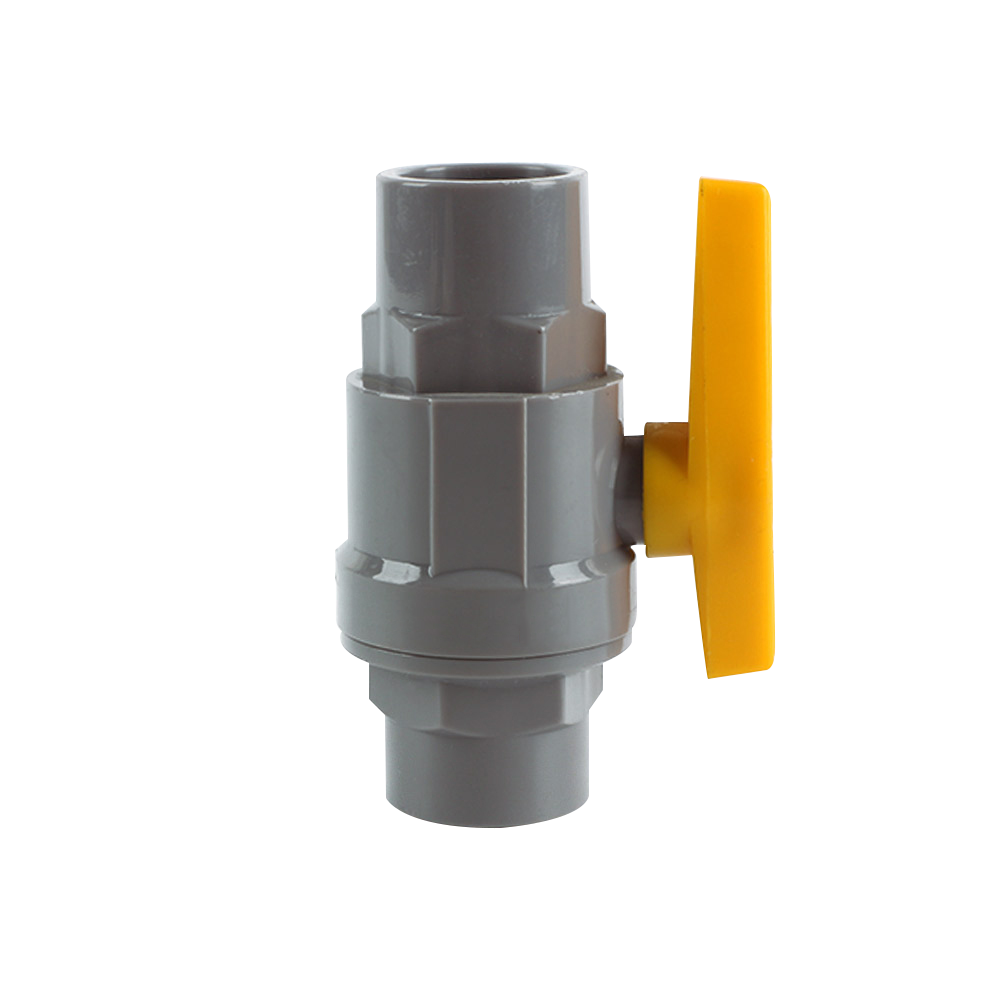

China Manufacturer of High-Quality Sockt Ball Valves for Your Needs

If you're in the market for a reliable sock ball valve, you’ve come to the right place. Our sock ball valves are designed for optimal performance and durability, making them an essential component for various industrial applications. As a leading manufacturer in China, we prioritize quality and precision in our products. I understand that choosing the right valve can be crucial for your operations, and that’s why our sock ball valves are engineered to provide maximum efficiency and long-lasting service. With customizable options and competitive pricing, we strive to meet your specific needs while ensuring timely delivery. Let’s work together to enhance your project’s performance; our expert team is ready to support you with any inquiries. Trust in our commitment to excellence and let our sock ball valves be your go-to solution for all your fluid control needs.

sockt ball valve in 2025 From Concept to Delivery

In the rapidly evolving world of industrial automation, the sock ball valve is emerging as a pivotal component for various applications. As we look ahead to 2025, the journey of sock ball valves from concept to delivery is set to revolutionize efficient fluid control systems across multiple industries. These valves are distinguished by their unique design, which combines the functionality of traditional ball valves with the added advantage of enhanced flow characteristics. This results in reduced pressure drops and minimized turbulence, making them an ideal choice for precise control in demanding environments. The development and manufacturing process of sock ball valves involves cutting-edge technology and rigorous testing to ensure reliability and performance. As global procurement professionals seek high-quality components, the focus has shifted towards valves that not only meet industry standards but also provide exceptional durability and longevity. By optimizing materials and refining production techniques, manufacturers are poised to deliver sock ball valves that can withstand extreme conditions and deliver consistent results over time. This ensures that businesses can maintain operational efficiency while minimizing downtime and maintenance costs. As we approach 2025, the demand for sock ball valves is expected to grow significantly, driven by advancements in automation and the need for sustainable solutions. Procurement specialists should be prepared to adapt to this trend by sourcing innovative products that align with their operational goals. Collaboration with leading manufacturers will be crucial in harnessing the benefits of these advanced valves and ensuring timely delivery and support. Embracing this technology will not only enhance fluid management systems but also support broader initiatives aimed at improving energy efficiency and reducing environmental impact in industrial settings.

Sockt Ball Valve in 2025: From Concept to Delivery

| Aspect | Details |

|---|---|

| Material Selection | Stainless Steel, Brass, PVC |

| Operating Pressure | Up to 150 PSI |

| Temperature Range | -20°C to 120°C |

| Control Type | Manual, Electric, Pneumatic |

| Applications | Water Treatment, Oil & Gas, Chemical Processing |

| Regulatory Compliance | ANSI, API, ISO Standards |

| Expected Lifespan | 10-15 Years |

| Market Trends | Increasing demand for automation and smart valves |

| Future Innovations | Integration with IoT for monitoring and control |

Related Products