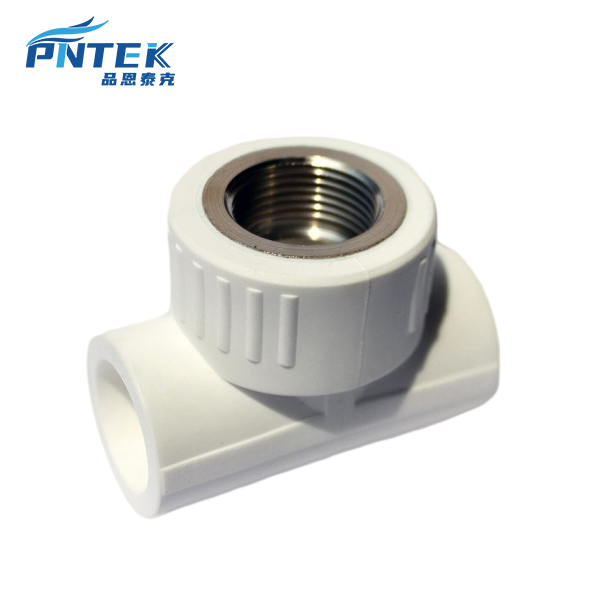

Top China Manufacturer of High-Quality Ball Valves for Every Need

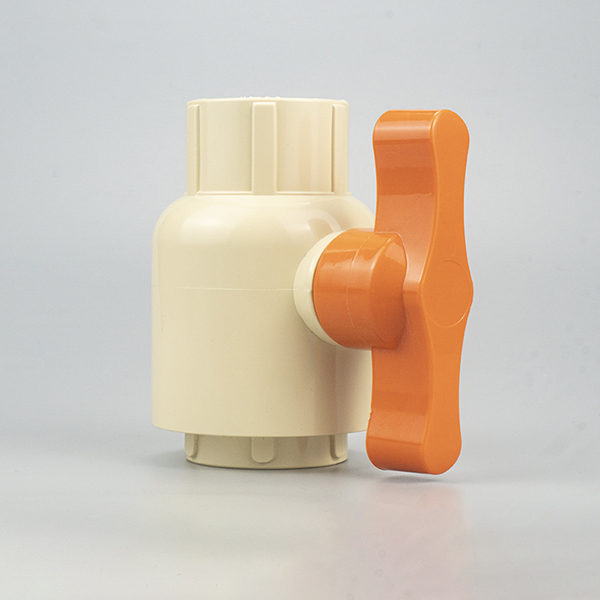

When it comes to sourcing high-quality valves, I understand that you need reliable solutions for your projects. Our Ball Valves, manufactured in China, offer exceptional durability and performance. With precision engineering, these valves guarantee smooth operation and efficient flow control in various applications. I know how crucial it is to find a trustworthy manufacturer who meets your quality standards. That's why our production process adheres to strict quality control measures, ensuring you receive only the best products. Whether you’re in the oil and gas industry or looking for solutions in HVAC systems, our Ball Valves can meet your specific needs. Choosing the right valve can make a significant difference in your operations, and I'm here to help you make an informed decision. Let’s simplify your procurement process with our competitive pricing and excellent customer service. Connecting with us means you’re getting a reliable partner for your valve requirements.

Valves Ball Valve Application Guarantees Peak Performance

Valves are essential components in various industrial applications, and the performance of ball valves is critical to ensuring operational efficiency. A well-designed ball valve not only guarantees tight sealing and consistent flow but also enhances safety and reliability in fluid management systems. For industries ranging from oil and gas to water treatment and pharmaceuticals, choosing the right ball valve can dramatically impact overall performance and cost-effectiveness. One of the key advantages of ball valves lies in their simplicity and durability. With a straightforward design featuring a spherical disc, they offer low resistance to flow, minimizing pressure drops and energy consumption. This is particularly beneficial for global buyers looking to optimize their processes while maintaining high standards of functionality. Furthermore, advancements in materials and manufacturing techniques have led to the development of ball valves that can withstand extreme conditions, such as high pressure and temperature variations, making them suitable for a wide range of applications. When sourcing ball valves, it is crucial to consider factors like material compatibility, size specifications, and certification standards. A supplier that understands the unique demands of different industries can provide tailored solutions that ensure peak performance. As manufacturers increasingly focus on sustainability and innovation, investing in high-quality ball valves can lead to significant long-term savings and enhance operational efficiency on a global scale.

Valves Ball Valve Application Guarantees Peak Performance

| Application | Industry | Size Range | Pressure Rating | Temperature Range | Material |

|---|---|---|---|---|---|

| Water Supply | Municipal | 1 inch - 12 inches | 150 psi | 32°F to 140°F | Brass |

| Natural Gas | Oil & Gas | 2 inch - 16 inches | 300 psi | -20°F to 150°F | Carbon Steel |

| Chemical Processing | Chemical | 0.5 inch - 10 inches | 150 psi | -40°F to 200°F | Stainless Steel |

| HVAC Systems | Building Services | 1 inch - 6 inches | 125 psi | 32°F to 180°F | Bronze |

| Fire Protection | Fire Safety | 2 inch - 12 inches | 250 psi | 32°F to 200°F | Ductile Iron |

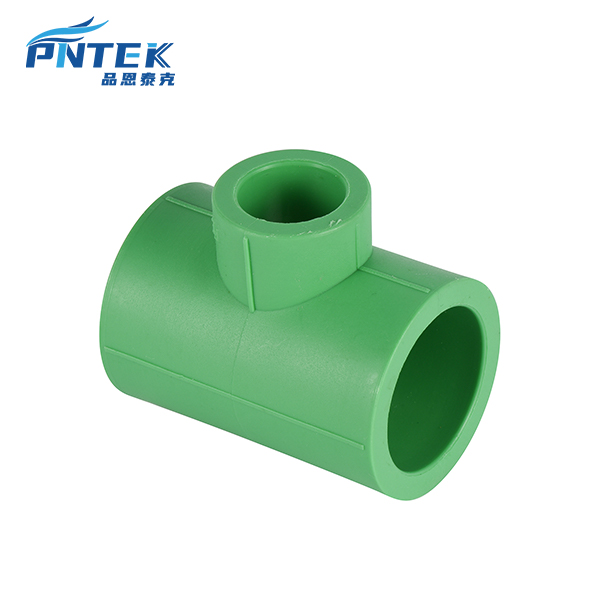

Related Products

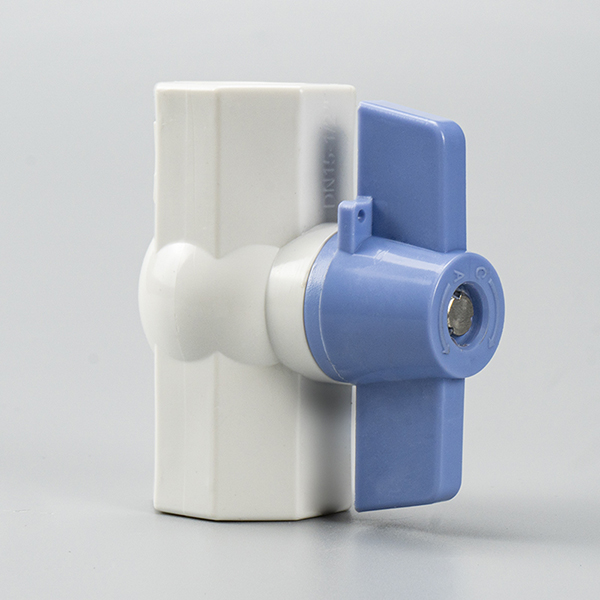

China Supplier PVC Compact Ball valve water Ball Valve with Blue body hydraulic valves Thailand

Read More