Available Sizes of HDPE Pipes Fitting from China Manufacturer

When it comes to HDPE pipe fittings, understanding the available sizes is crucial for making the right choice for your project. I’ve found that as a buyer, knowing the different options can save both time and money. Sourced directly from a reliable manufacturer in China, our selection of HDPE fittings caters to various applications and ensures durability and longevity. From small diameters suitable for residential plumbing to larger sizes designed for industrial use, we have a comprehensive range of sizes. I appreciate that our products are crafted with high-quality materials that comply with international standards. If you're seeking dependable solutions that enhance efficiency and performance, our HDPE pipe fittings are definitely worth considering. Let's connect and discuss how our offerings can meet your specific needs.

Available Sizes Of Hdpe Pipes Fitting For the Current Year Now Trending

In the ever-evolving landscape of industrial materials, high-density polyethylene (HDPE) pipes and fittings have emerged as a preferred choice for various applications due to their durability, corrosion resistance, and ease of installation. As we move through this year, understanding the available sizes of HDPE pipe fittings is crucial for global buyers aiming to secure the best solutions for their projects. From small-scale agricultural systems to large municipal pipelines, the versatility of HDPE fittings allows for seamless integration into diverse infrastructures. Currently, the trending sizes for HDPE pipe fittings include a range from 20mm to 450mm in diameter, catering to a multitude of specifications. The most sought-after sizes include 25mm, 32mm, 50mm, and 110mm, which are frequently utilized in irrigation systems, drainage, and potable water supply. Buyers should also be aware of custom sizes that can be produced based on specific project requirements, enabling tailored solutions that meet unique operational demands. The rising trend towards sustainability and environmental responsibility in construction further highlights the importance of choosing HDPE fittings, as they are not only cost-effective but also contribute to reducing the carbon footprint of infrastructure projects. For procurement professionals, staying informed about the latest trends in HDPE pipe fittings is essential to optimize project efficiency and reduce costs. By exploring global suppliers and understanding the specifications relevant to their needs, buyers can ensure they are equipped with the best materials available this year. As industries continue to prioritize innovation and sustainability, HDPE fittings will undoubtedly play a pivotal role in shaping the future of pipeline solutions.

Available Sizes Of Hdpe Pipes Fitting For the Current Year Now Trending

| Size (Inch) | Outer Diameter (mm) | Wall Thickness (mm) | Length (m) | Standard |

|---|---|---|---|---|

| 1/2 | 20 | 2 | 6 | ASTM D3035 |

| 3/4 | 25 | 2.5 | 6 | ASTM D3035 |

| 1 | 32 | 3 | 6 | ASTM D3035 |

| 1 1/4 | 42 | 3.5 | 6 | ASTM D3035 |

| 1 1/2 | 48 | 4 | 6 | ASTM D3035 |

| 2 | 60 | 5 | 6 | ASTM D3035 |

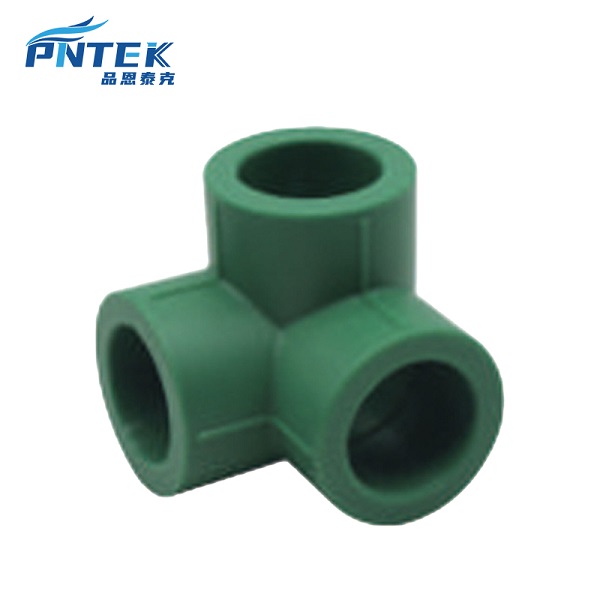

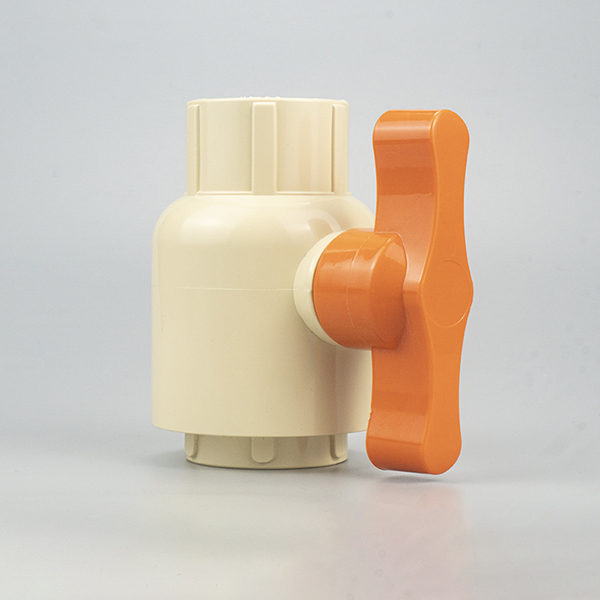

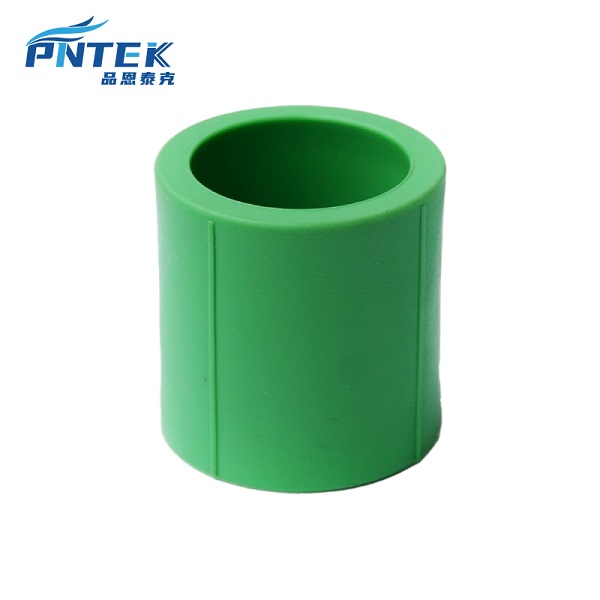

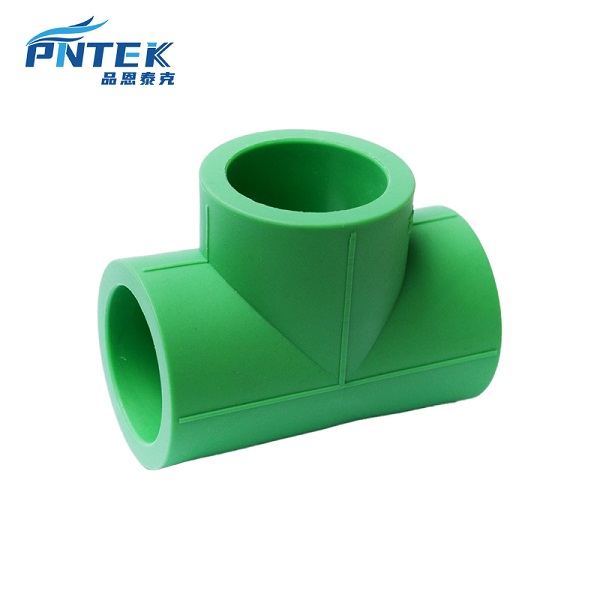

Related Products