Top China HDPE Fittings Manufacturer for Quality Solutions

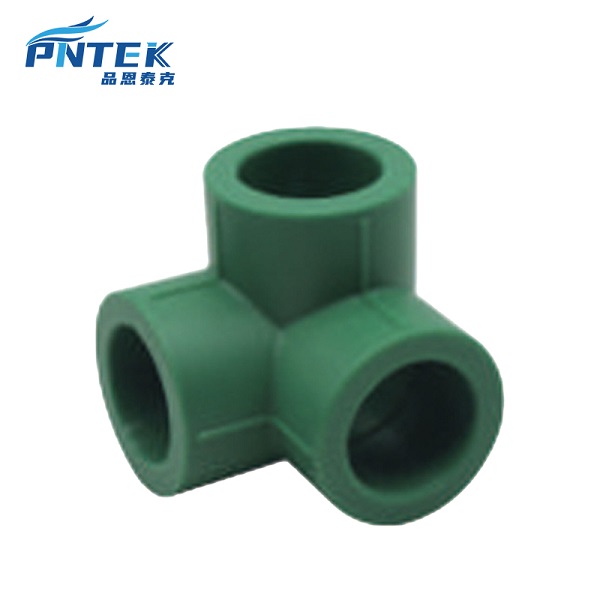

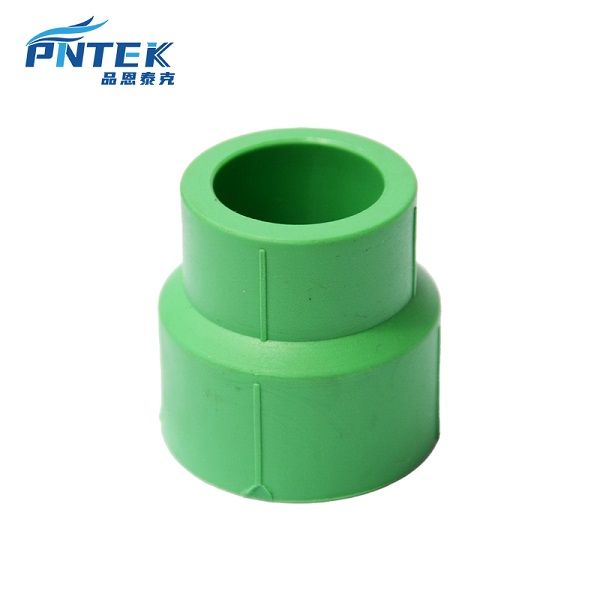

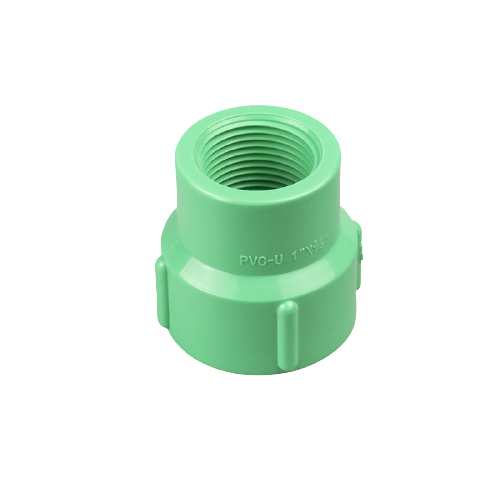

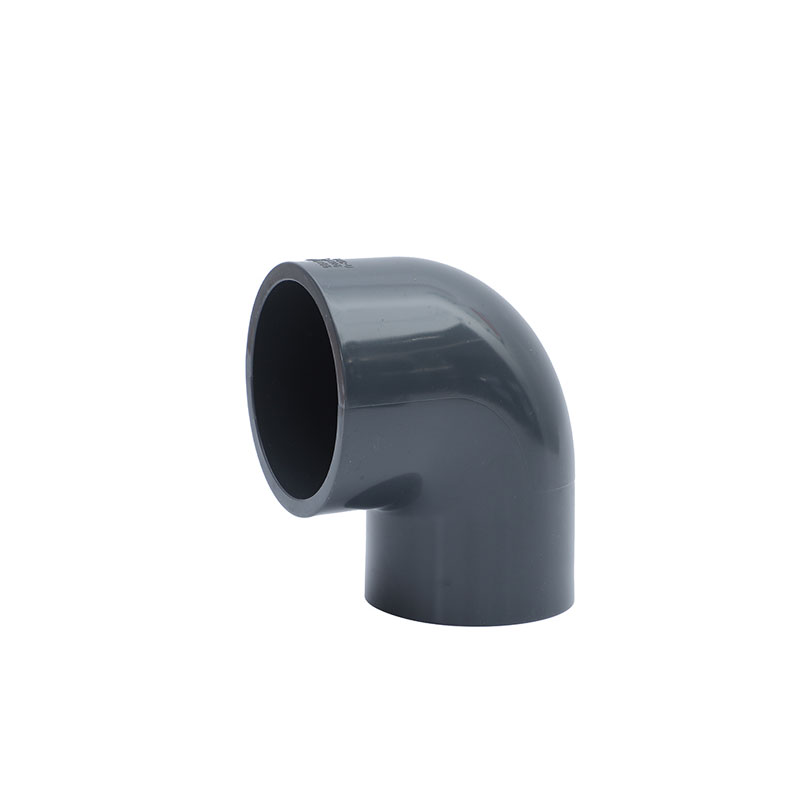

When it comes to sourcing reliable HDPE fittings from China, I understand the importance of quality and performance for your projects. As a manufacturer with years of experience, we deliver durable and versatile solutions that meet industry standards and requirements. Our HDPE fittings are designed for easy installation, offering exceptional resistance to corrosion and chemicals, ensuring longevity in various applications. I’ve seen firsthand how our products have helped businesses streamline their operations while maintaining a commitment to sustainability. With a wide range of sizes and types, our fittings cater to diverse needs, whether for water supply, gas distribution, or industrial applications. I take pride in collaborating closely with our clients to understand their specific needs, ensuring that the fittings we supply fit perfectly with their systems. If you’re looking to partner with a dependable manufacturer, I invite you to reach out and explore the range of HDPE fittings we offer.

China Hdpe Fittings Application in 2025

As we move towards 2025, the application of HDPE fittings in various sectors is poised to expand significantly, driven by the growing demand for durable and efficient piping solutions. With industries increasingly focusing on sustainability, HDPE (High-Density Polyethylene) fittings are becoming a popular choice due to their exceptional resistance to corrosion, lightweight nature, and ease of installation. This material not only provides a long service life but also minimizes maintenance costs, making it an ideal solution for both industrial and municipal applications. Globally, the construction, irrigation, and water management sectors are expected to spearhead the adoption of HDPE fittings. In developing regions, the push towards modern infrastructure development and improved water supply systems will further catalyze the demand for reliable and cost-effective piping solutions. Additionally, the growing trend of establishing eco-friendly systems will drive manufacturers and contractors to opt for HDPE, thanks to its recyclable properties and lower environmental impact compared to traditional materials. Furthermore, innovations in manufacturing processes and the development of new technologies will enhance the capabilities of HDPE fittings, offering even greater efficiency and performance. As procurement professionals evaluate their supply chains, the emphasis on reliable suppliers who can provide high-quality, compliant products will be paramount. In this evolving landscape, staying attuned to market dynamics and emerging applications will be essential for global buyers looking to leverage HDPE fittings in their projects.

China Hdpe Fittings Application in 2025

| Application Area | Market Size (Million USD) | Growth Rate (%) | Key Features |

|---|---|---|---|

| Water Supply Systems | 1200 | 5.2 | Corrosion Resistance, Lightweight |

| Agricultural Irrigation | 800 | 6.0 | Flexibility, UV Resistant |

| Construction and Infrastructure | 1500 | 4.8 | Durability, Cost-Effectiveness |

| Chemical Processing | 600 | 7.5 | Chemical Resistance, High Temperature Tolerance |

| Mining and Quarrying | 400 | 6.3 | Strength, Wear Resistance |

Related Products