Top Control Valve Manufacturers in China for Quality Solutions

When it comes to reliable control valves, I’ve found that the quality from China’s top manufacturers truly stands out. These control valves are engineered for precision and efficiency, ideal for various industrial applications. I appreciate how their durable construction can withstand harsh conditions while maintaining optimal performance. The manufacturers I work with focus on the latest technology to ensure that their products meet international standards. Whether it’s for regulating flow, pressure, or temperature, you can trust these control valves to perform exceptionally. What I really value is the commitment to customer satisfaction. The flexibility in design and customization options means I can find the perfect match for my operational needs. If you’re in the market for dependable control valves from a trusted Chinese manufacturer, I highly recommend exploring these options. You won’t be disappointed with the quality and service provided.

Control Valve Winning in 2025 Where Service Meets Innovation

In the rapidly evolving landscape of industrial automation, control valves stand at the intersection of service and innovation, paving the way for enhanced efficiency and reliability. As we look toward 2025, the demand for advanced control valve technologies is expected to surge, driven by the growing emphasis on sustainability and operational excellence in various sectors, from oil and gas to water treatment. This shift necessitates a robust understanding of market dynamics, and global procurement professionals need to adapt quickly to identify solutions that not only meet current needs but also anticipate future challenges. Innovation in control valve design and functionality is key to addressing the complexities of modern operational environments. The integration of smart technologies, such as IoT sensors and predictive maintenance analytics, empowers organizations to optimize their processes, ensuring that control valves are not only responsive but also data-driven. Additionally, embracing sustainable materials and energy-efficient designs aligns with global efforts for greener industrial practices. Procurement teams must be vigilant in sourcing products that embody these innovations, fostering partnerships with manufacturers dedicated to quality and sustainability. Ultimately, the synergy between exceptional service and cutting-edge innovation will define the market leading control valve solutions by 2025. An unwavering commitment to supporting clients—not just during the purchase phase, but throughout the entire lifecycle of the product—will be crucial. By focusing on enhancing customer experience through technical support, training, and rapid response times, procurement professionals can ensure they select partners who are as dedicated to their success as they are, transforming potential challenges into opportunities for growth and efficiency.

Control Valve Winning in 2025 Where Service Meets Innovation

| Dimension | Value | Comments |

|---|---|---|

| Market Growth Rate (%) | 8.5 | Increasing demand for automation |

| Technological Innovations | IoT Integration | Enhances efficiency and monitoring |

| Key Industries | Oil & Gas, Water Treatment | Major consumers of control valves |

| Sustainability Trends | Energy Efficiency | Focus on reducing emissions |

| Future Outlook | Smart Control Systems | Expected to dominate the market |

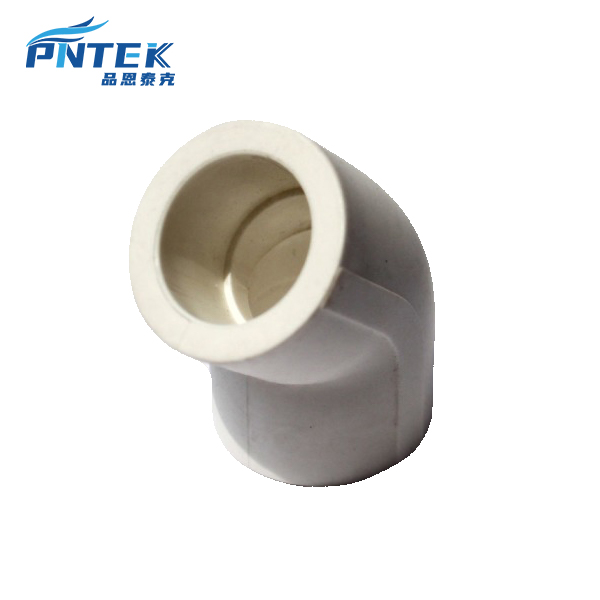

Related Products