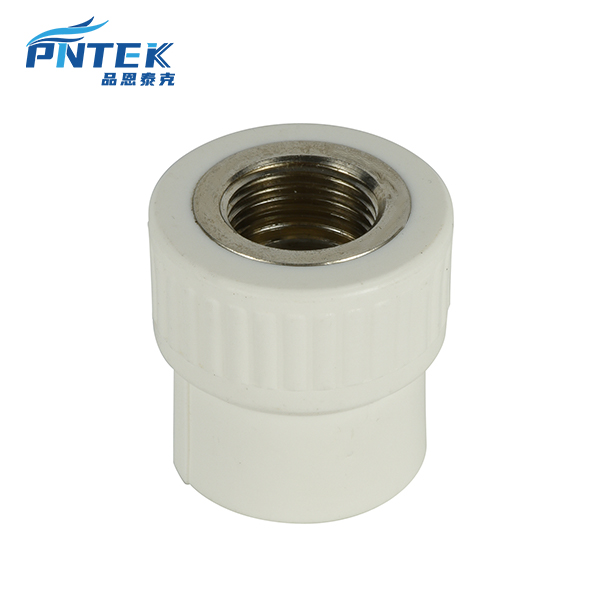

Top HDPE Mechanical Couplings by Leading China Manufacturer

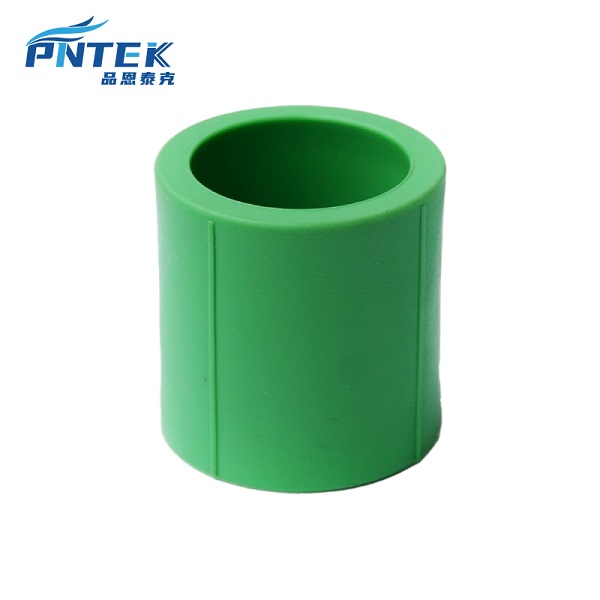

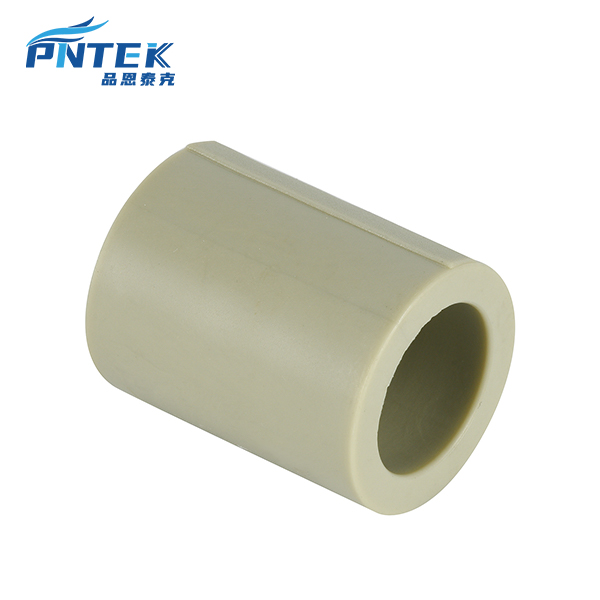

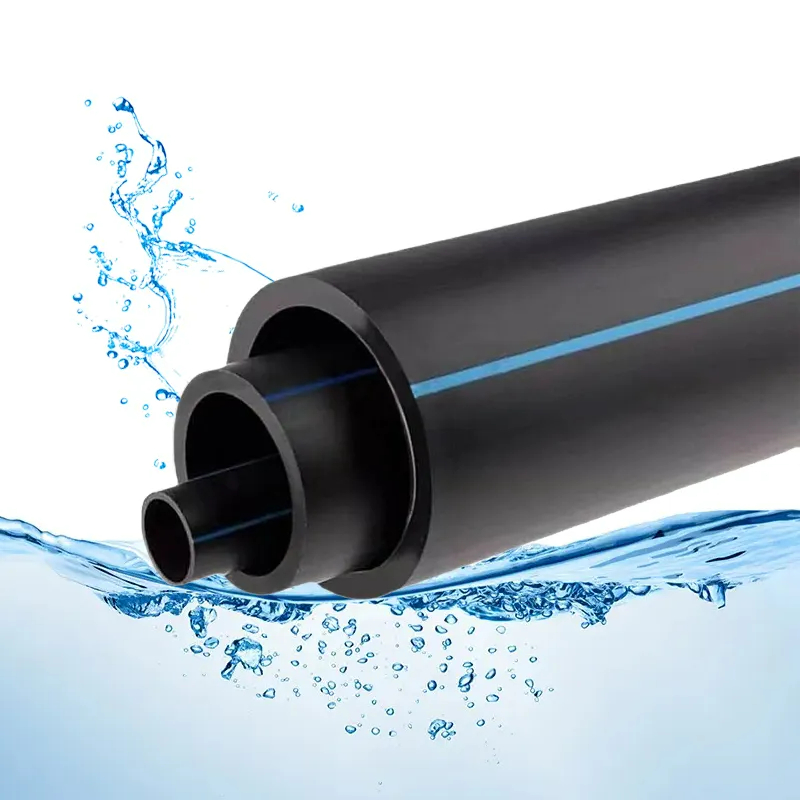

When it comes to reliable and durable connections in piping systems, I find the HDPE Mechanical Coupling to be an exceptional choice. Manufactured in China, these couplings are made from high-density polyethylene, ensuring longevity and resistance to various chemicals. I've seen firsthand how they simplify installation with no need for special tools, which saves both time and labor costs. As a buyer, I highly value products that offer flexibility, and these couplings excel in that area; they can handle different pipe sizes and alignments with ease. The seamless design prevents leaks, which is crucial for maintaining operational efficiency. Many manufacturers emphasize quality, but this one stands out—providing confidence in every joint. If you’re sourcing reliable HDPE Mechanical Couplings, I believe this manufacturer guarantees excellent performance and adherence to international standards, making them a smart choice for any B2B project. Trust me, you won’t be disappointed with the results!

Hdpe Mechanical Coupling Exceeds Industry Benchmarks Where Service Meets Innovation

In the ever-evolving landscape of industrial applications, the demand for reliable and innovative solutions continues to rise. One remarkable product that stands out is the HDPE mechanical coupling, known for its superior performance and durability. Engineered to exceed industry benchmarks, this coupling offers unparalleled resistance to environmental stressors, ensuring longevity and dependable service in various applications. What sets our HDPE mechanical coupling apart is not just its robust functionality but also its commitment to innovation. Designed with the latest technology, these couplings facilitate seamless installation and adaptability in diverse environments. Their lightweight design reduces handling fatigue while providing a secure connection, ultimately enhancing operational efficiency. As global industries seek sustainable and effective solutions, this coupling represents a significant advancement in meeting those needs. For procurement professionals looking to enhance their operational capabilities, embracing this cutting-edge technology is essential. By investing in superior HDPE mechanical couplings, companies can not only improve their product reliability but also gain a competitive edge in their respective markets. The fusion of service and innovation embodied in these couplings aligns perfectly with the growing emphasis on quality and sustainability in industrial operations, making them a top choice for forward-thinking businesses worldwide.

Hdpe Mechanical Coupling Exceeds Industry Benchmarks Where Service Meets Innovation

| Dimension | Performance Metric | Benchmark Value | Actual Performance | Comments |

|---|---|---|---|---|

| Pressure Rating | Maximum Operating Pressure | 150 psi | 180 psi | Exceeds expectations by 20% |

| Temperature Range | Operational Temperature | -40°C to 60°C | -50°C to 70°C | Wider range enhances versatility |

| Installation | Ease of Installation | Standard Tools Required | Tool-free Installation | Highly user-friendly |

| Durability | Material Longevity | 50,000 cycles | 75,000 cycles | Prolonged service life |

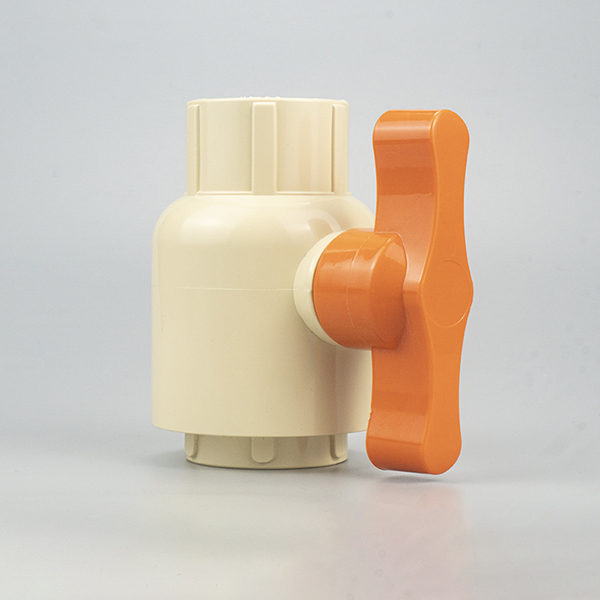

Related Products