Top China Manufacturer of HDPE Molded Fittings for Quality Solutions

When you need durable and reliable solutions for your piping systems, I’m excited to present our HDPE molded fittings crafted for various industrial applications. Sourced from a trusted China manufacturer, these fittings are engineered to meet the highest standards of quality and performance. They offer excellent resistance to corrosion, chemicals, and UV rays, ensuring longevity in even the toughest environments. With a comprehensive range of sizes and configurations available, I can help you find the perfect fit for your project needs. Buying from us not only guarantees superior products but also ensures you’re partnering with a company that values customer satisfaction. Let’s simplify your supply chain with our cost-effective solutions and exceptional service. Together, we can achieve the efficiency and reliability your operations demand. If you're ready to elevate your piping systems, do reach out for samples and pricing details!

Hdpe Molded Fittings Products in 2025

As we look ahead to 2025, the landscape of HDPE molded fittings is anticipated to be shaped by technological advancements and evolving market needs. The demand for high-density polyethylene (HDPE) fittings is on the rise due to their durability, corrosion resistance, and ability to withstand harsh environmental conditions. Industries such as construction, plumbing, and agriculture are increasingly adopting HDPE fittings for their reliability and long lifespan, making them an attractive option for global purchasers. Sustainability considerations are also driving the market forward. Manufacturers are focusing on creating eco-friendly solutions that not only provide the necessary performance but also minimize environmental impact. With enhanced recycling processes and innovative production techniques, the future of HDPE molded fittings is set to align with global sustainability goals. This presents a significant opportunity for buyers looking for high-quality, sustainable products that meet modern regulatory standards. In addition, advancements in manufacturing technology are poised to improve the efficiency and cost-effectiveness of HDPE fitting production. Automation and smart manufacturing processes are expected to reduce lead times and enhance product quality. As the industry progresses towards more customized solutions, purchasers can look forward to tailored offerings that meet specific project requirements. By staying informed about these trends, global buyers can make strategic procurement decisions that align with their operational needs and sustainability commitments.

Hdpe Molded Fittings Products in 2025

| Product Name | Type | Size (inches) | Standard | Application | Material Grade |

|---|---|---|---|---|---|

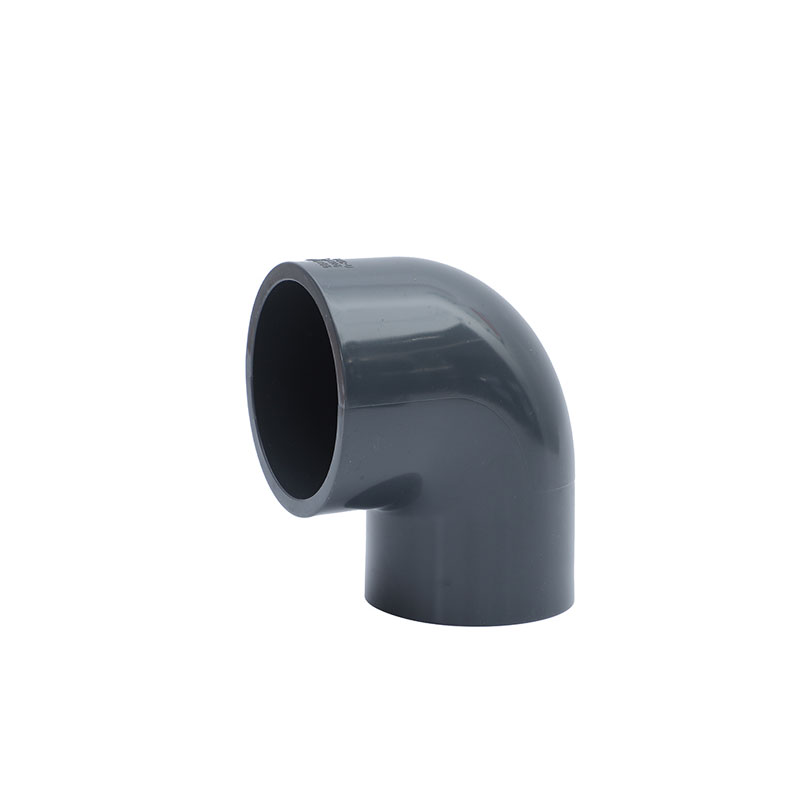

| HDPE Elbow | Elbow | 2 | ASTM D2683 | Water Supply | PE80 |

| HDPE Tee | Tee | 3 | ASTM D3035 | Irrigation | PE100 |

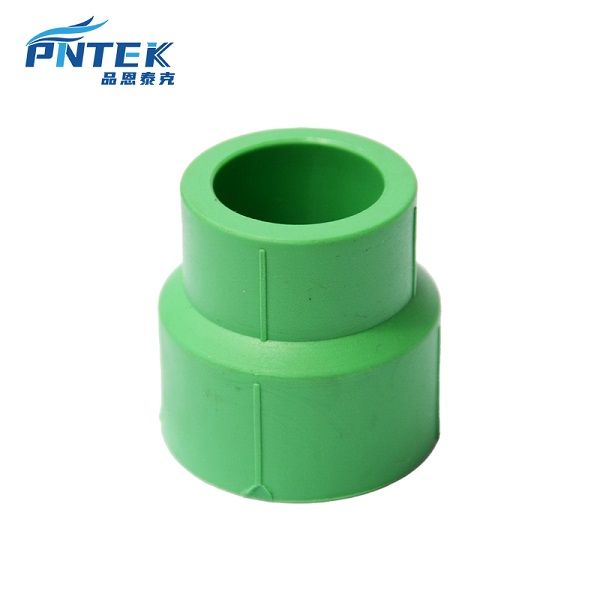

| HDPE Reducer | Reducer | 4 to 2 | ISO 4427 | Gas Supply | PE80 |

| HDPE Cap | Cap | 6 | ASTM D2239 | Sewage System | PE100 |

| HDPE Socket | Socket | 1 | AS/NZS 4130 | Drainage | PE80 |

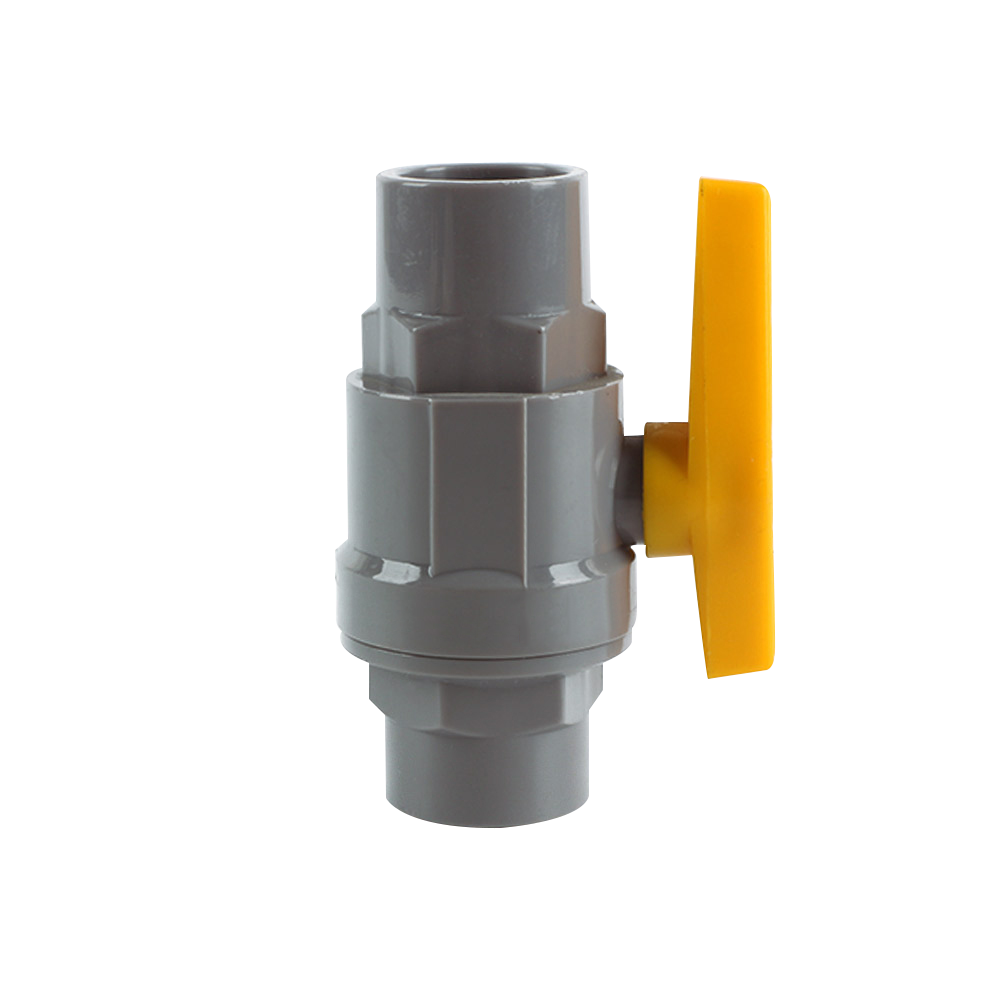

Related Products