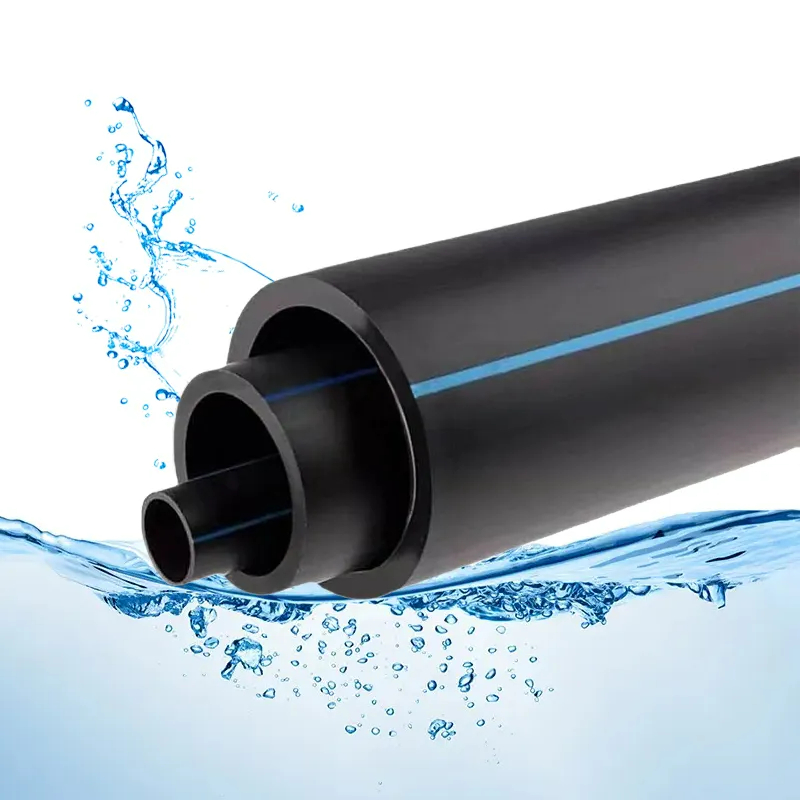

Hdpe Pipe Joints Manufacturer in China: Quality Solutions for Projects

When it comes to reliable and durable plumbing solutions, I find that HDPE pipe joints stand out. Manufactured in China, our HDPE joints are engineered to ensure a secure connection for various applications, from water supply to industrial projects. I appreciate that these joints are not only resistant to corrosion but also flexible enough to withstand ground movement, making them ideal for diverse environments. In my experience, the quality of these products is unmatched, which is crucial for long-term performance. By choosing our HDPE pipe joints, you’re not just securing a product; you're investing in sustainability and efficiency. Each joint goes through rigorous testing, ensuring they meet high manufacturing standards. Whether you're a supplier or a contractor, these joints will meet your project requirements and exceed your expectations. Reach out if you're ready to elevate your plumbing solutions with quality HDPE joints from a trusted manufacturer in China.

Hdpe Pipe Joints in 2025 Where Service Meets Innovation

As we look ahead to 2025, the landscape of HDPE pipe joints is poised for significant transformation, driven by a relentless pursuit of innovation and enhanced service delivery. The demand for high-density polyethylene (HDPE) pipes is steadily rising due to their superior resistance to corrosion, longevity, and flexibility compared to traditional materials. This increasing popularity among global procurement professionals is met with technological advancements that ensure these joint systems meet the rigorous standards of modern infrastructure projects. One of the most exciting trends is the integration of smart technologies in HDPE pipe joint manufacturing. Innovations such as IoT-enabled monitoring systems allow for real-time tracking of joint performance, ensuring optimal functionality and reducing the risk of failures. Additionally, advancements in joint design are emphasizing ease of installation and maintenance, minimizing downtime and costs for end-users worldwide. As global markets increasingly focus on sustainability, these developments are crucial in aligning with eco-friendly initiatives, making HDPE an even more attractive option for large-scale projects. In conclusion, by 2025, HDPE pipe joints will likely embrace a perfect blend of cutting-edge technology and superior service standards, offering global procurement specialists the reliability and efficiency needed in modern construction and infrastructure endeavors. Staying ahead of trends in service and innovation will be critical for businesses aiming to lead in this competitive market. Embracing these changes will not only facilitate smoother operations but also drive significant value for stakeholders across the globe.

Hdpe Pipe Joints in 2025 Where Service Meets Innovation

| Joint Type | Material | Max Pressure (psi) | Temperature Range (°F) | Installation Method | Innovation Features |

|---|---|---|---|---|---|

| Electrofusion Joint | HDPE | 160 | -40 to 180 | Electrical Fusion | Self-monitoring capabilities |

| Butt Fusion Joint | HDPE | 200 | -40 to 140 | Heat Fusion | Rapid jointing process |

| Mechanical Joint | HDPE | 150 | 0 to 100 | Bolted Connection | Ease of disassembly |

| Socket Fusion Joint | HDPE | 130 | -40 to 140 | Heat Fusion | Compact design for tight spaces |

| Compression Joint | HDPE | 100 | 0 to 80 | Compression Fitting | Seals without heat |

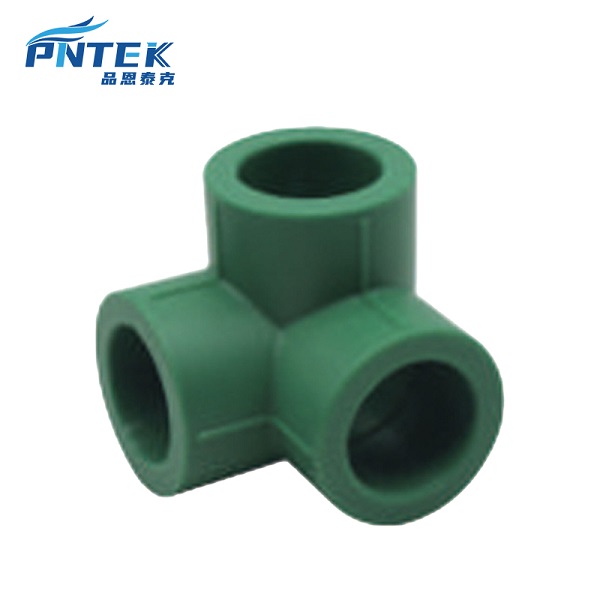

Related Products