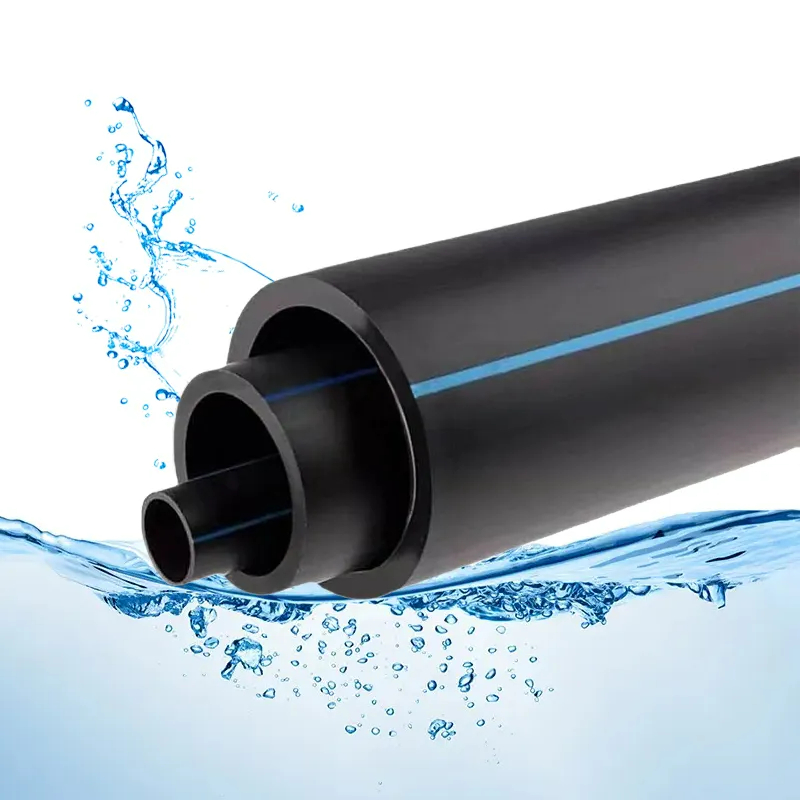

Hdpe Spiral Pipe Fitting Manufacturer in China - Quality & Reliability

Our HDPE spiral pipe fittings offer unmatched durability and flexibility, perfect for a variety of industrial applications. Sourced directly from trusted manufacturers in China, we ensure top-notch quality that meets your specific needs. Having worked extensively within the industry, I understand the importance of reliable fittings in maintaining seamless operations. These fittings are designed to withstand high pressure and harsh conditions, making them an ideal choice for projects requiring resilience. With competitive pricing and excellent service, we are committed to helping you reduce costs without compromising on quality. If you’re seeking a dependable solution to streamline your projects, our HDPE spiral pipe fittings are the answer. Let’s elevate your operations together—reach out today to learn more about how our products can support your business needs.

Hdpe Spiral Pipe Fitting Delivers Unmatched Quality Where Innovation Meets 2025

In the ever-evolving world of industrial solutions, the demand for high-performance materials and components is more critical than ever. As businesses strive for efficiency and sustainability, the significance of high-density polyethylene (HDPE) spiral pipe fittings cannot be overstated. These innovative fittings offer unparalleled quality and durability, essential for overcoming the challenges of various industrial applications in 2025 and beyond. The use of HDPE spiral technology not only enhances structural integrity but also provides excellent resistance to corrosion, making it ideal for fluid transport in a myriad of industries. Moreover, the adaptability of HDPE allows for easier installation and maintenance, ensuring that procurement managers can achieve their operational goals with minimized downtime and costs. As global trends shift towards sustainable practices, the superior lifecycle of HDPE products further aligns with the needs of environmentally conscious companies. By investing in HDPE spiral pipe fittings, businesses are not just enhancing their infrastructure; they are also committing to a greener future, which is increasingly appealing to conscientious buyers. In conclusion, the integration of advanced materials like HDPE in pipe fitting solutions represents a pivotal movement in industrial manufacturing. As we move into 2025, the focus on innovation and quality will continue to drive procurement decisions, positioning HDPE spiral pipe fittings as a vital component for international suppliers aiming to enhance their product offerings and establish a competitive edge in the marketplace. Unlocking the potential of these fittings can lead to transformative benefits for operations worldwide.

Hdpe Spiral Pipe Fitting Delivers Unmatched Quality Where Innovation Meets 2025

| Dimension (mm) | Material Type | Pressure Rating (bar) | Temperature Range (°C) | Application Area |

|---|---|---|---|---|

| 110 | HDPE | 10 | -40 to 60 | Water Supply |

| 160 | HDPE | 16 | -40 to 60 | Irrigation |

| 200 | HDPE | 10 | -40 to 60 | Sewage |

| 250 | HDPE | 16 | -40 to 60 | Industrial |

Related Products