High Quality Pipe Valves from Leading China Manufacturer

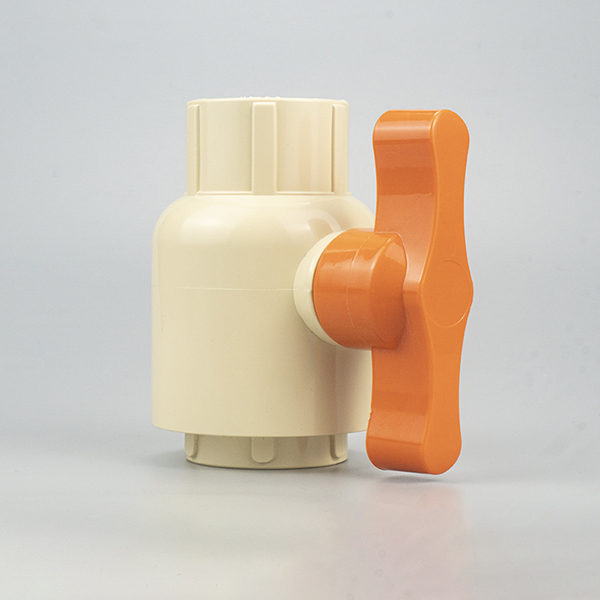

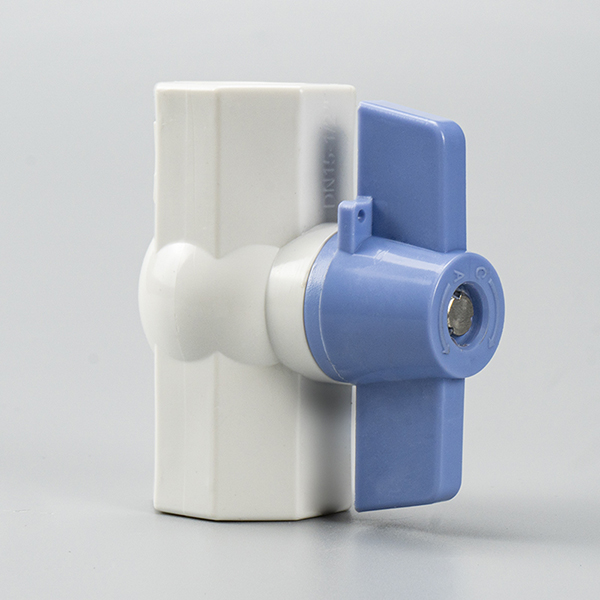

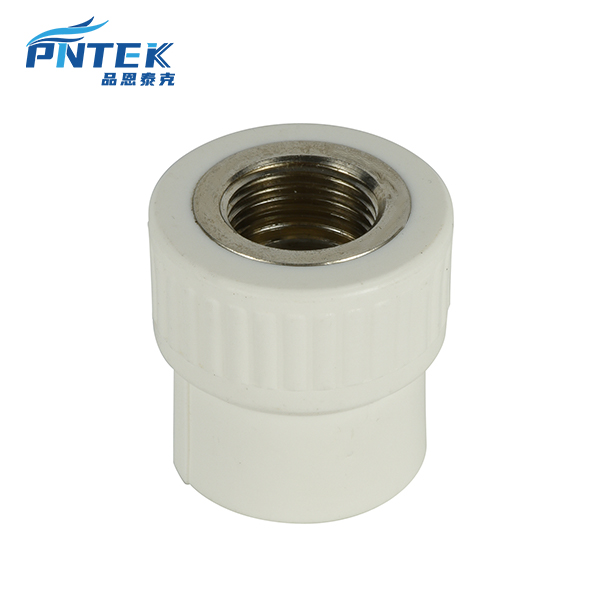

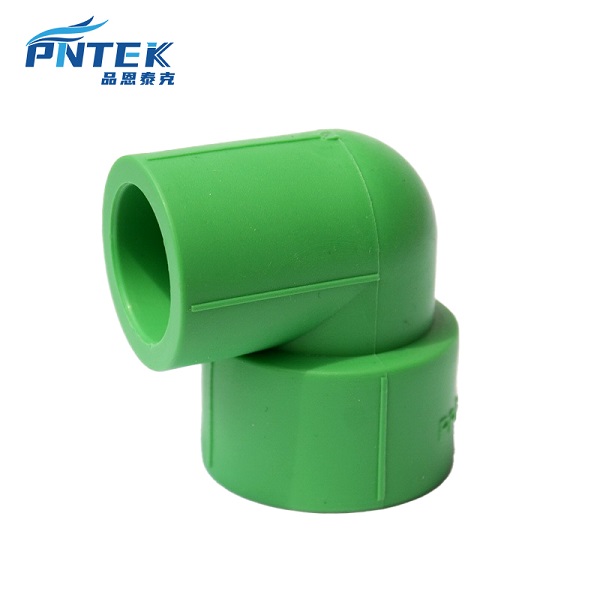

As a buyer in search of high quality pipe valves, I understand the importance of choosing a reliable manufacturer. I’ve found that sourcing from a trusted China manufacturer ensures I get durable and efficient products. With a focus on precision engineering, these valves are designed to meet stringent industry standards, making them ideal for various applications. I appreciate the diversity in designs and materials available, allowing me to tailor my orders to meet specific needs. The commitment to quality control in their production process not only guarantees performance but also longevity—saving me maintenance costs in the long run. Collaborating with a manufacturer that prioritizes innovation and customer satisfaction makes my procurement process smooth and worry-free. Whether I'm working on plumbing, industrial, or HVAC applications, knowing I have access to top-notch pipe valves from China gives me confidence in my projects.

High Quality Pipe Valves Winning in 2025 Factory-Direct Excellence

In today's competitive landscape, sourcing high-quality pipe valves is paramount for industries relying on reliable fluid control solutions. As we approach 2025, the call for factory-direct excellence has never been more vital. By cutting through the traditional supply chain complexities, factories can provide procurement professionals with top-tier products, often at reduced costs and improved delivery times. This direct relationship not only offers transparency in pricing but also fosters a deeper understanding of product specifications and compliance with industry standards. Investing in high-quality pipe valves means ensuring durability and performance. These components are critical in various applications, from petrochemical facilities to water treatment plants. As global procurement professionals make their purchasing decisions, they seek out manufacturers committed to rigorous quality control processes. This guarantees that each valve not only meets but exceeds industry standards, thus minimizing downtime and maintenance costs. Furthermore, innovative manufacturing techniques and materials are paving the way for more resilient and efficient valve designs, catering to the evolving demands of the market. As we move towards 2025, the emphasis on sustainability and efficiency will continue to shape procurement strategies. Companies that invest in state-of-the-art manufacturing technologies are better positioned to deliver products that not only perform but also adhere to environmental regulations. By partnering with a supplier focused on these values, procurement professionals can ensure they are making responsible choices that benefit both their operations and the planet. Embracing factory-direct excellence in sourcing high-quality pipe valves is not merely a trend but a strategic approach that can yield significant long-term benefits.

High Quality Pipe Valves Winning in 2025 Factory-Direct Excellence

| Valve Type | Material | Connection Type | Size (inches) | Temperature Rating (°C) | Pressure Rating (PSI) |

|---|---|---|---|---|---|

| Gate Valve | Carbon Steel | Flanged | 2 | 120 | 150 |

| Ball Valve | Stainless Steel | Socket Weld | 3 | 150 | 300 |

| Check Valve | Bronze | Threaded | 1.5 | 80 | 200 |

| Globe Valve | PVC | Clamp | 4 | 60 | 100 |

| Butterfly Valve | Cast Iron | Wafer | 6 | 80 | 150 |

Related Products