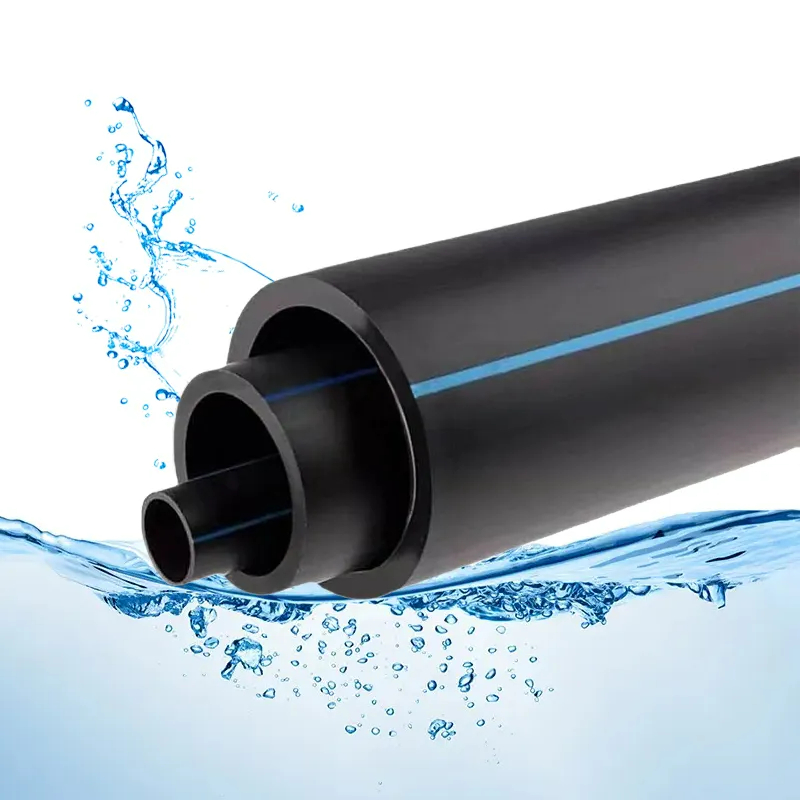

Top HDPE Pipe Fitting Manufacturers in China - Quality You Can Trust

As a dedicated player in the industry, I understand the importance of quality in your projects. Our HDPE pipe fittings are crafted to the highest standards, making them a reliable choice for any application. Aimed at businesses seeking robust solutions, we proudly manufacture these fittings right here in China. Their durability and resistance to corrosion ensure long-lasting performance, meaning fewer replacements and lower maintenance costs for you. We focus on providing competitive pricing without compromising quality, allowing you to maximize your project budgets. Whether you need fittings for water supply, irrigation, or industrial purposes, our range can meet your demands. Let's connect and discuss how our HDPE pipe fittings can enhance your operations and help achieve your project goals efficiently. Your success is our priority!

Pipe Fitting Hdpe in 2025 Industry Leaders

As we look towards 2025, the landscape of the pipe fitting industry, particularly in the realm of HDPE (High-Density Polyethylene), is set to transform drastically. The growing demand for durable, lightweight, and resistant materials is driving innovations and advancements in production techniques. Global procurement professionals are increasingly focused on sourcing HDPE pipe fittings that not only meet strict quality standards but also align with sustainability goals. In this evolving market, understanding the dynamics of supplier capabilities and the latest technological innovations is essential for making informed purchasing decisions. A significant trend on the horizon is the integration of smart technology into pipe fitting solutions. As industries move towards automation, HDPE fittings that feature advanced monitoring and control systems will become more prevalent. This shift not only enhances operational efficiency but also helps in reducing maintenance costs. Procurement leaders must therefore prioritize suppliers who are at the forefront of these technological advancements and can provide comprehensive solutions that meet the growing demands of various sectors, including construction, agriculture, and water management. Moreover, with the global emphasis on sustainability, sourcing from environmentally responsible manufacturers will become increasingly vital. Buyers should seek HDPE products that are produced using recycled materials and efficient processes that reduce carbon footprints. Collaboration with manufacturers dedicated to sustainable practices not only ensures compliance with future regulations but also enhances brand reputation. As we move closer to 2025, keeping an eye on these trends will empower procurement professionals to make strategic sourcing decisions that boost their competitive edge in the international market.

Pipe Fitting Hdpe in 2025 Industry Leaders

| Leader Name | Market Share (%) | Product Line Variety | Region | Sustainability Initiatives |

|---|---|---|---|---|

| Leader A | 25 | High-Density PE, Fittings, Valves | North America | Recycling Programs, Eco-Friendly Materials |

| Leader B | 20 | Water Systems, Drainage Solutions | Europe | Carbon Offset Projects, Reduced Waste |

| Leader C | 15 | Industrial Fittings, Pipes | Asia | Sustainable Sourcing, Energy Efficiency |

| Leader D | 10 | Residential Solutions, Custom Products | Latin America | Water Conservation, Eco-Design |

| Leader E | 30 | Agricultural, Irrigation Systems | Africa | Plastic Reduction, Community Projects |

Related Products