PPR Ball Valves Manufacturer in China: Quality & Efficiency Guaranteed

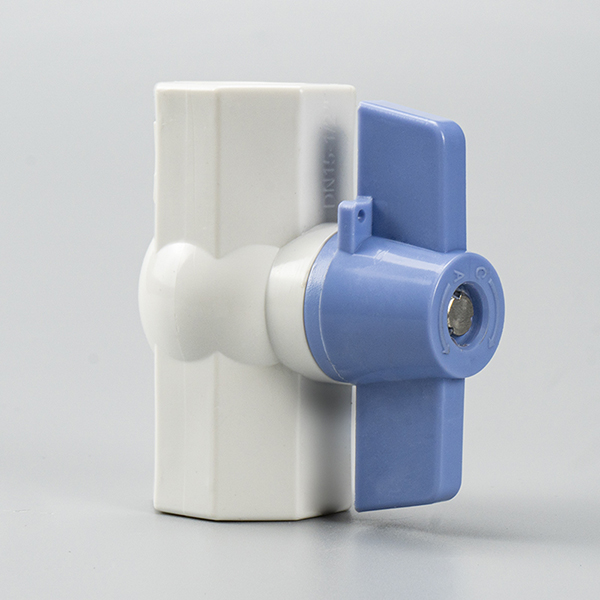

As a B2B purchaser seeking reliable solutions, I find PPR Ball Valves to be an essential component in plumbing and industrial applications. Sourced from a trusted manufacturer in China, these valves are crafted with precision and durability in mind. The lightweight yet robust design ensures easy installation and long-lasting performance, suitable for various fluid transfer tasks. I appreciate how these PPR Ball Valves resist corrosion and scaling, which means less maintenance and increased efficiency for our operations. Whether I'm working on a plumbing project or a larger industrial setup, these valves deliver both functionality and sustainability. Plus, the seamless integration with existing systems simplifies upgrades and installations. When partnering with a manufacturer like the ones in China, I ensure that quality meets affordability. I can confidently choose PPR Ball Valves to enhance our systems while maintaining budget constraints, making them an integral part of my procurement strategy.

PPR Ball Valves Industry Leaders From Concept to Delivery

In the world of industrial components, PPR ball valves have emerged as essential players in fluid control systems. These innovative products are known for their reliability, corrosion resistance, and cost-effectiveness, making them the go-to choice for various industries worldwide. From concept to delivery, the journey of these valves is meticulously crafted to meet the diverse needs of global procurers, ensuring that they receive high-quality solutions designed for both performance and longevity. The production process of PPR ball valves begins with rigorous design engineering, utilizing advanced technology to develop products that meet international standards. Once the design is finalized, the materials used are carefully selected to guarantee durability and resistance to a wide range of chemicals and temperatures. This attention to detail continues through the manufacturing phase, where skilled technicians and automated processes collaborate to produce valves that are not only functional but also adhere to precise specifications. Finally, ensuring customer satisfaction extends beyond delivery. Comprehensive quality control measures are implemented throughout the manufacturing process to guarantee that each valve performs optimally upon installation. Robust after-sales support and technical assistance complete the package, ensuring that global buyers receive not just a product, but a commitment to excellence that supports their operational needs for years to come. By choosing PPR ball valves, businesses can confidently enhance their operational efficiency while enjoying peace of mind in the quality and reliability of their equipment.

PPR Ball Valves Industry Leaders From Concept to Delivery

| Manufacturing Process | Material Type | Connection Type | Operating Pressure (Bar) | Temperature Range (°C) |

|---|---|---|---|---|

| Injection Molding | PPR | Socket Weld | 10 | 0 to 60 |

| Extrusion | PP-RCT | Threaded | 16 | -20 to 95 |

| Blow Molding | PPRC | Fusion Weld | 20 | 10 to 80 |

| Machining | PVC | Flanged | 5 | 0 to 70 |

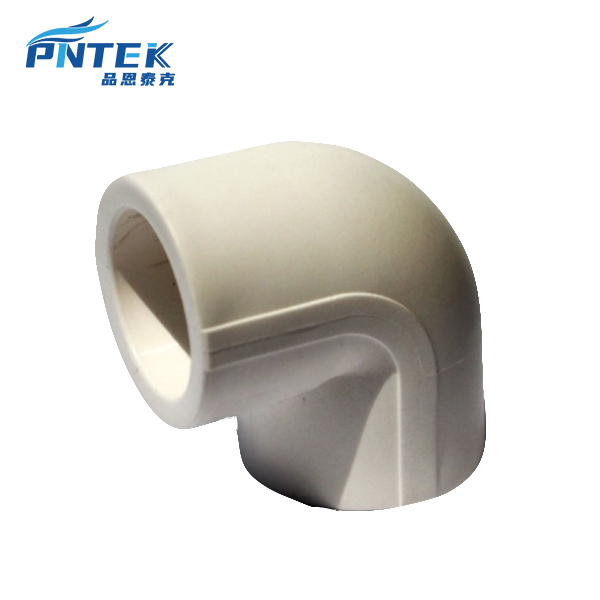

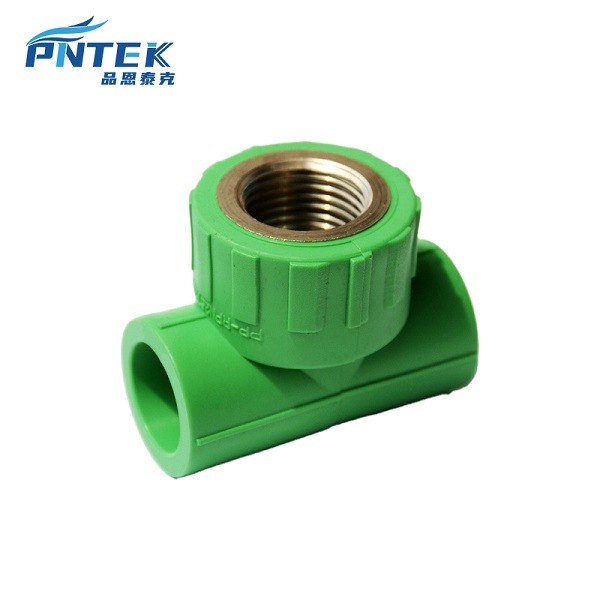

Related Products

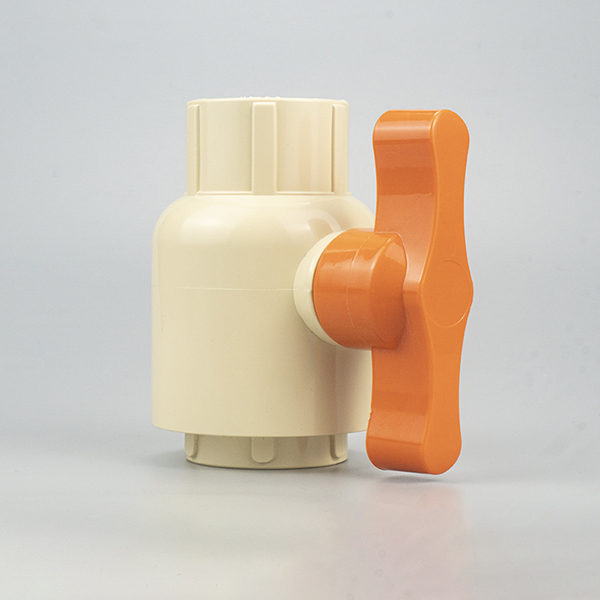

Top Quality PVC Ball Valves Pipe Fittings Two-pieces Ball Valve With Green Color Plastic Handle Stainless Steel Handle 3M Valve

Read More