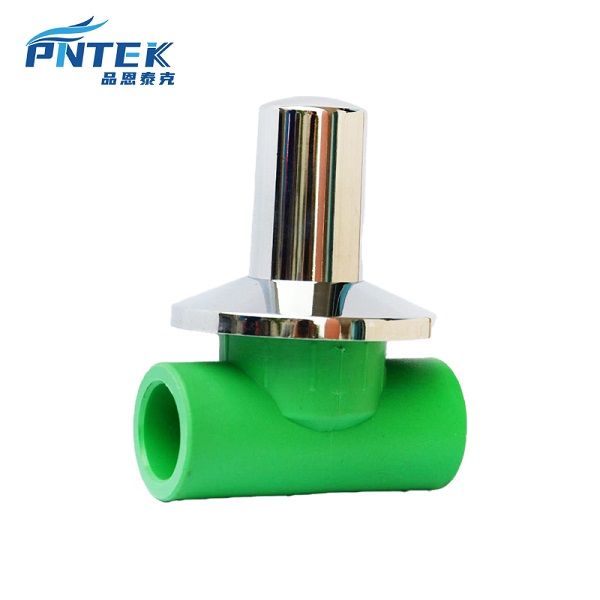

Find High-Quality Socket Ball Valves from Trusted China Manufacturers

When it comes to reliability and performance, our Socket Ball Valve stands out in the market. Designed with precision, this valve ensures a tight seal and smooth operation, making it ideal for various industrial applications. As a leading manufacturer in China, we prioritize quality in every product we offer. Our Socket Ball Valve is crafted from durable materials, ensuring longevity and resistance to corrosion, which is essential for efficient fluid control. Plus, our competitive pricing helps you maximize your budget without compromising on quality. Whether you’re in oil and gas, water treatment, or any other sector, you’ll find that our product meets stringent quality standards. Let me help you enhance your operations with our reliable Socket Ball Valve. Get in touch with us to learn more about how we can fulfill your specific needs right from our factory in China!

Socket Ball Valve Dominates Winning in 2025

In an increasingly competitive global market, the socket ball valve is emerging as a key player for businesses looking to enhance their operational efficiency and fluid management systems. As industries continue to evolve, the demand for robust, reliable, and high-performance valves is on the rise. The versatility and adaptability of socket ball valves make them an ideal choice for various applications, from oil and gas to water treatment and chemical processing. By 2025, it's projected that the socket ball valve will dominate the marketplace, offering unparalleled advantages such as ease of installation, improved flow control, and minimal maintenance requirements. With their straightforward design, these valves significantly reduce leakage risks while ensuring optimal performance under pressure. Moreover, the growing emphasis on sustainability and environmental protection is driving innovations in valve technology, and socket ball valves are at the forefront of this trend, employing advanced materials that withstand corrosive environments. For global buyers, investing in socket ball valves not only promises greater reliability and operational savings but also aligns with the industry's shift towards smarter, more efficient technologies. As manufacturers embrace automation and IoT integration, the socket ball valve will play a crucial role in driving operational excellence and meeting future demands. Adopting these valves now positions businesses to thrive in a rapidly changing landscape, making them a preferred choice for procurement professionals looking to secure a competitive edge in 2025 and beyond.

Socket Ball Valve Dominates Winning in 2025

| Application | Material | Size (inches) | Operating Pressure (PSI) | Temperature Range (°F) | Market Share (%) |

|---|---|---|---|---|---|

| Water Supply | Brass | 1 | 150 | 32 to 140 | 25 |

| Chemical Processing | Stainless Steel | 2 | 200 | -20 to 250 | 30 |

| Oil & Gas | Carbon Steel | 3 | 300 | 32 to 350 | 20 |

| HVAC Systems | PVC | 1.5 | 100 | 32 to 140 | 15 |

| Food and Beverage | 316 Stainless Steel | 2.5 | 150 | 32 to 212 | 10 |

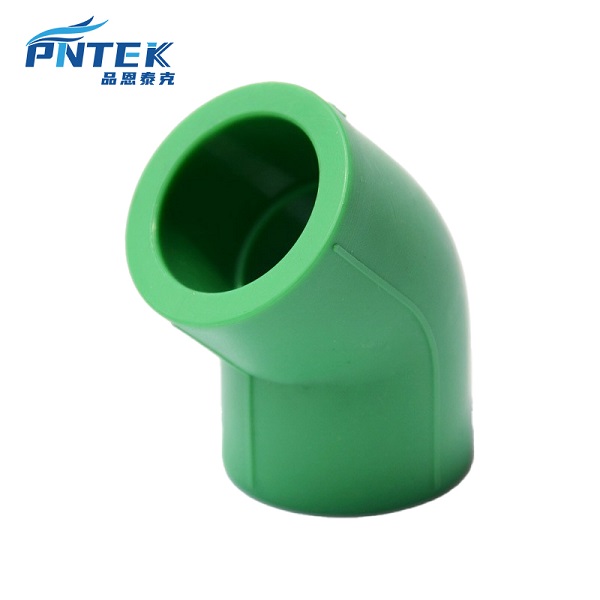

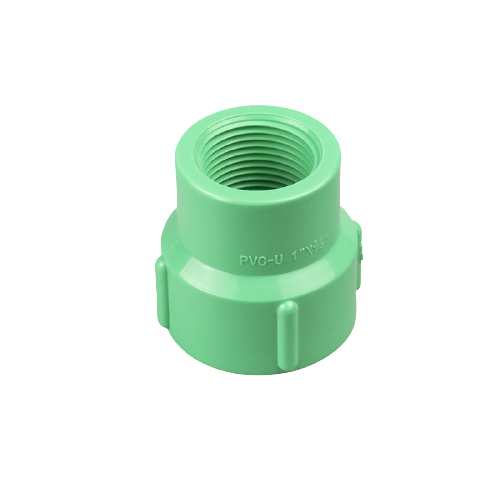

Related Products